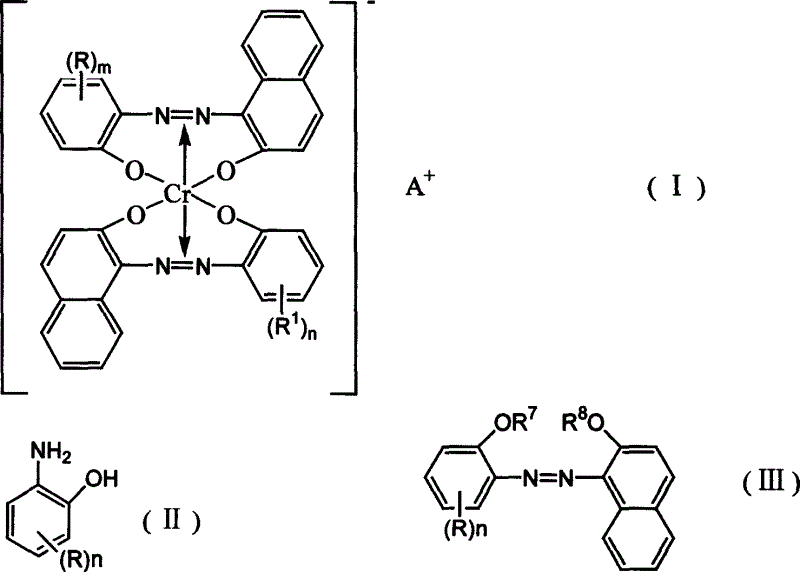

Method for preparing mono-azo 2:1 chromium complex dyes and and their use

A technology of chromium complexes and monoazo, which is applied in the direction of azo dyes, complex metal compounds of azo dyes, organic dyes, etc., can solve the undiscovered monoazo 2:1 type chromium complex dye preparation method and other issues, to achieve the effect of improving equipment utilization, high yield and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

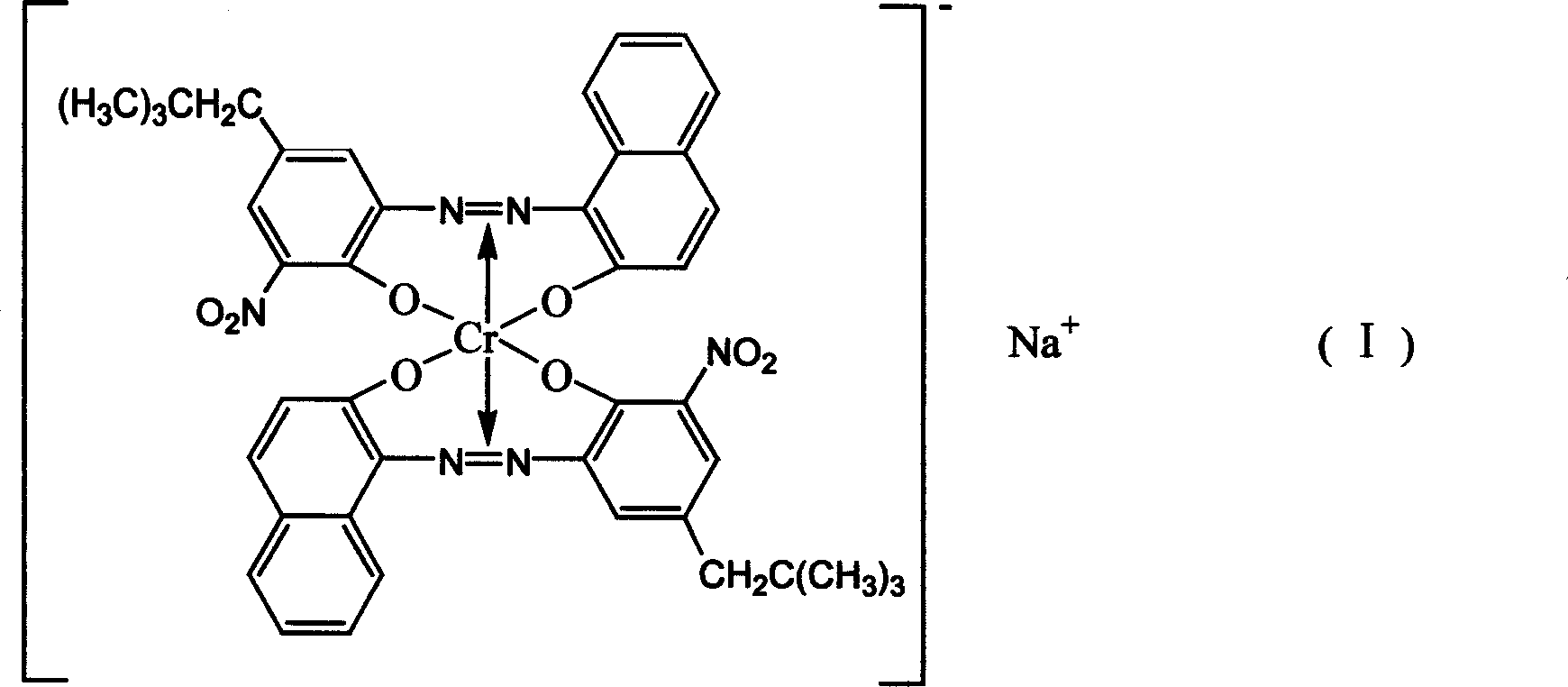

Embodiment 1

[0027]

[0028] 140 parts of double distilled water, 5.5 parts of sodium hydroxide, 31.96 parts of II (R=6-nitro and 4-neopentyl), 3 parts of nonionic surfactant (HLB=18), stirred at 20-25°C After 2-3 hours, add 9.4 parts of sodium nitrite and stir at 20-25°C for 1 hour. This mixture was then added to a solution containing 110 parts of water and 52.6 parts of hydrochloric acid and stirred at 0-15°C for 1 hour. Slowly add the diazonium reaction mixture prepared above to the dissolved solution containing 220 parts of twice distilled water, 12 parts of sodium hydroxide, and 20 parts of β-naphthol solution for coupling, and stir at 30-40°C for 2-3 Hour. The reaction mixture was filtered with a Buchner funnel, washed with water, and the filter cake was dried at 80°C to obtain 54 parts of III. The purity of III reaches 99.3% by HPLC analysis.

[0029] Mix the III prepared above with 45 parts of ethylene glycol, 30 parts of chromium lactate, and 9 parts of carbamide, and offset...

Embodiment 2-5

[0033] According to the method of Example 1, different Is were obtained respectively.

[0034]

Embodiment 6

[0036]

[0037] Three different kinds of II, respectively 7.2 parts of R=4-neopentyl; 6-nitro, 8 parts of R=5-nitro, 7.5 parts of R=4-nitro, in 110 parts of twice distilled water, 5.5 Parts of sodium hydroxide and 3 parts of nonionic surfactant (HLB=18) were mixed and stirred for 2 hours, then 9.7 parts of sodium nitrite was added, and then stirred at 20-25° C. for 1 hour. This mixture was added to a solution containing 110 parts of water and 52.6 parts of hydrochloric acid at 0-5°C and stirred at 0-5°C until the diazo reaction was complete.

[0038] Then the above-mentioned diazo reaction mixture was added to a solution containing 220 parts of twice distilled water, 12.3 parts of sodium hydroxide, 3.4 parts of sodium bicarbonate and 19.9 parts of β-naphthol at 10-20 ° C, and diluted with dilute hydroxide Sodium solution or hydrochloric acid solution adjusts the reaction pH to 8-9, and stirs the reaction at 30-40° C. for 2-4 hours. Then react at 70-90°C for 1 hour. Then f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com