Numerical control shearer

A shearing machine and machine body technology, applied in metal processing and other directions, can solve the problems of small starting torque of the geared motor, lower production efficiency, inaccurate stop position of the upper cutter, etc., and achieve the effect of large starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

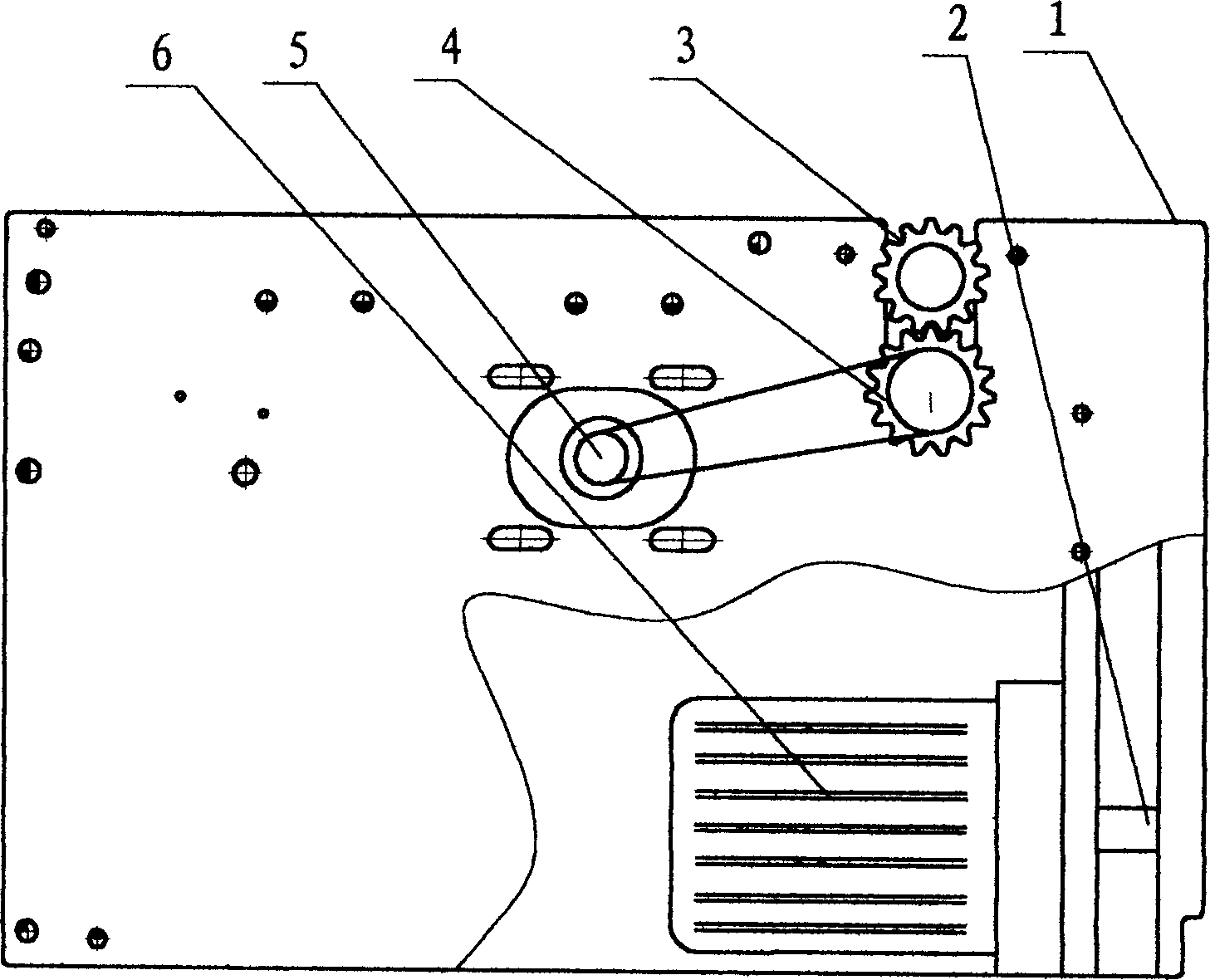

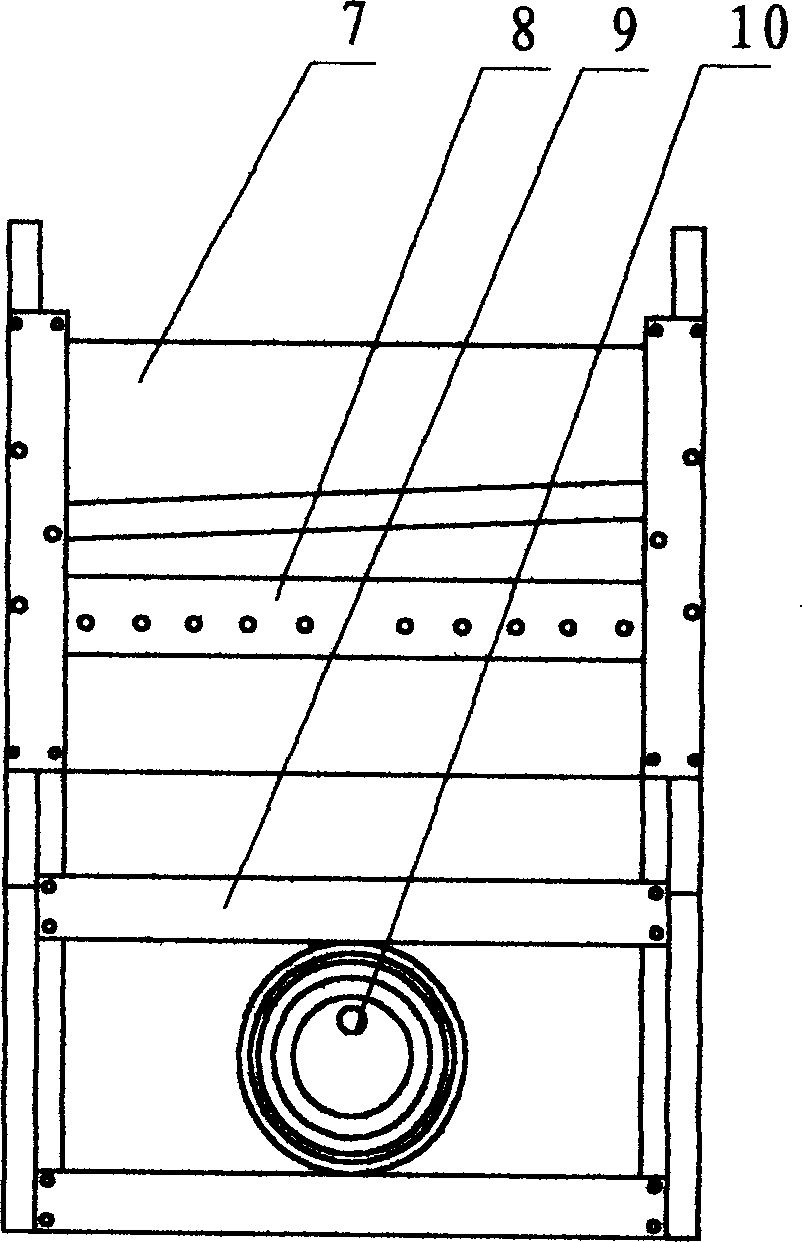

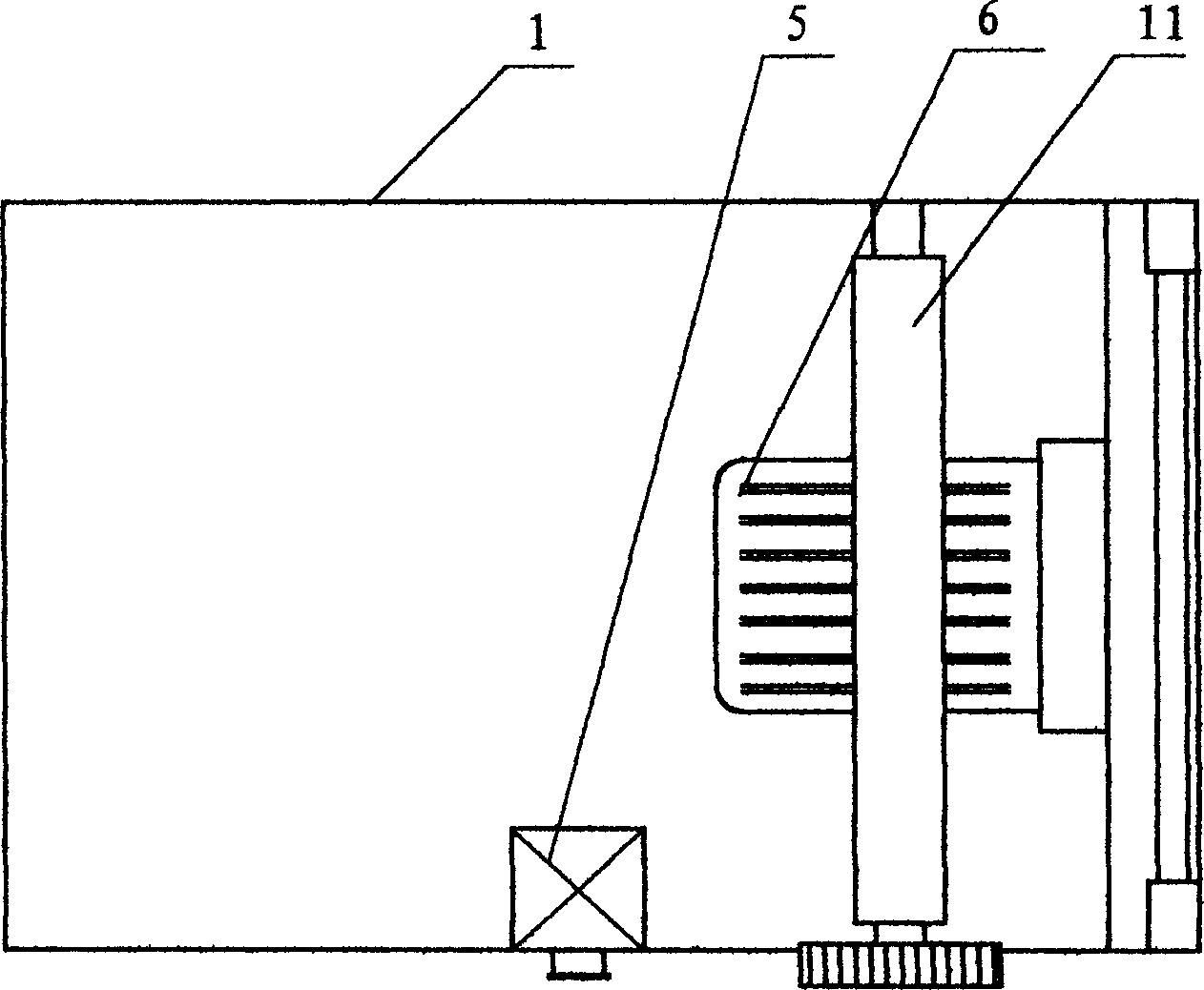

[0010] The accompanying drawings have shown the structure of the present invention and its embodiments, and further describe the relevant details of the embodiments below in conjunction with the accompanying drawings. This numerically controlled shearing machine comprises body 1, computer single-chip microcomputer (not shown in the figure) and feeding table 13, and described body 1 is provided with digital button 12, and the digital control of the present invention is realized by the input of these numerically controlled buttons 12 , the upper and lower feed rollers 11 are installed on the body 1, whether it is cutting hoses, films, or paper tapes, the raw materials are fed between the upper and lower feed rollers 11, and the body 1 is provided with a feeding roller. Stepper motor 5, the roller is connected to the feeding stepping motor 5, in this embodiment, the upper and lower feeding rollers are equipped with gears 3, 4, and the two gears mesh with each other, wherein the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com