Driving circuit for semiconductor laser

A driving circuit and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of unusable and damaged semiconductor lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

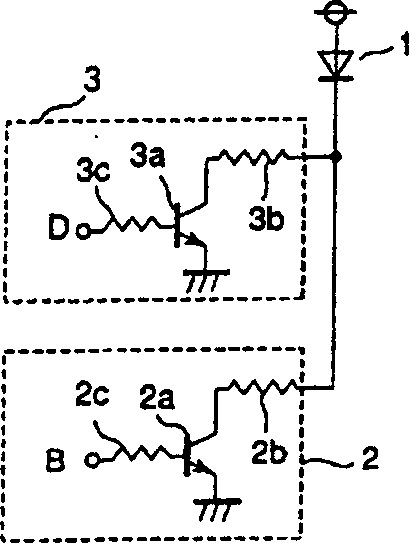

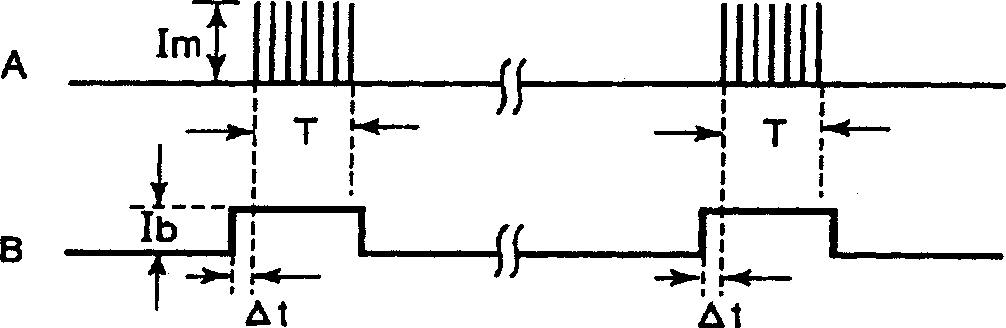

[0024] 32: According to Figure 1 to Figure 3 The driving circuit of the semiconductor laser of the present invention will be described. figure 1 Represent the structure of the drive circuit of the semiconductor laser of the present invention, figure 2 Indicates the light output characteristics of a semiconductor laser, image 3 Timing diagram showing modulation signal and bias current, Figure 5 Indicates other structures of the driving circuit of the semiconductor laser.

[0025] 33: in figure 1 , a specified voltage is applied to the anode of the semiconductor laser diode (single semiconductor laser) 1 . A bias current supply unit that supplies a bias current to the semiconductor laser 1 includes a first transistor (NPN type) 2 a connected in series with the semiconductor laser 1 . That is, the collector of the first transistor 2a is connected to the cathode of the semiconductor laser 1 through the resistor 2b for limiting the bias current, and the emitter is ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com