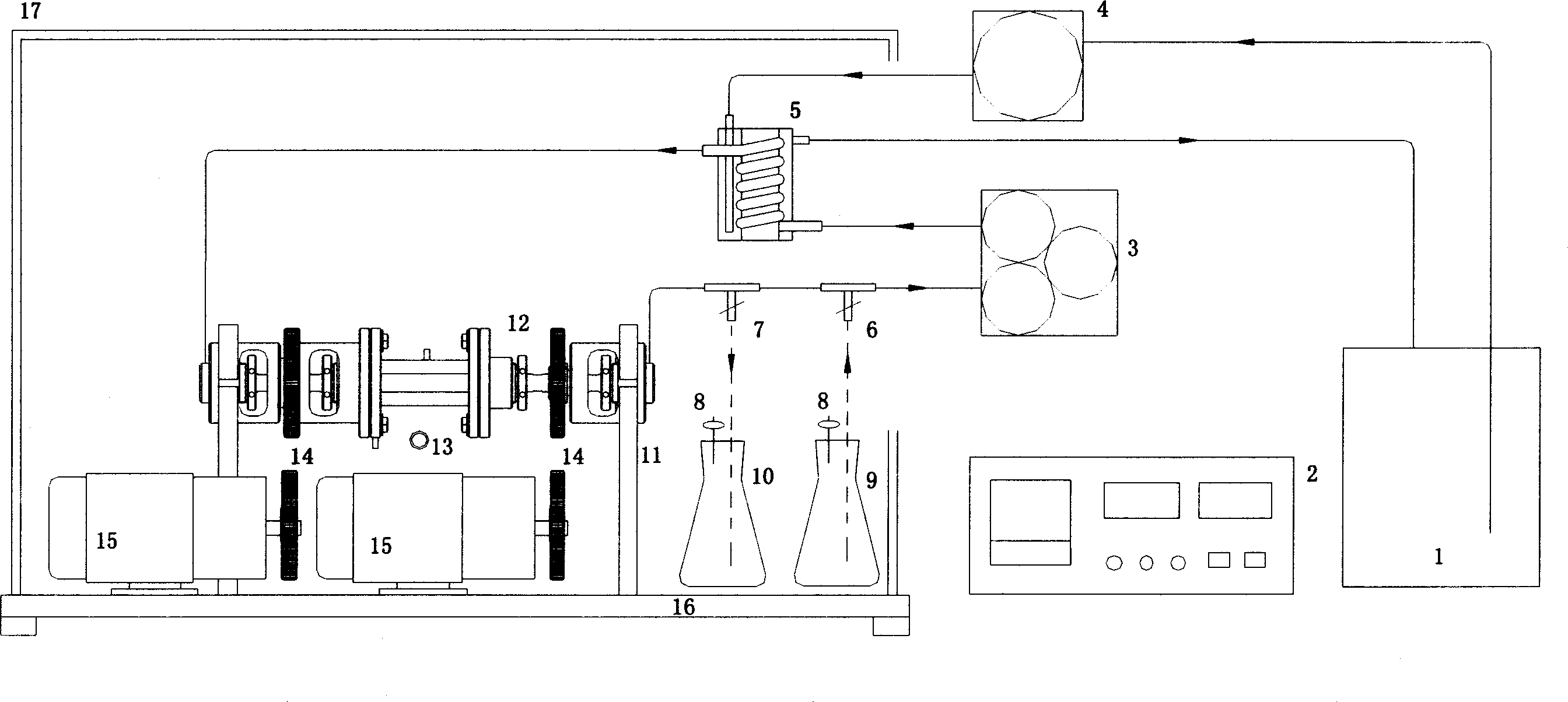

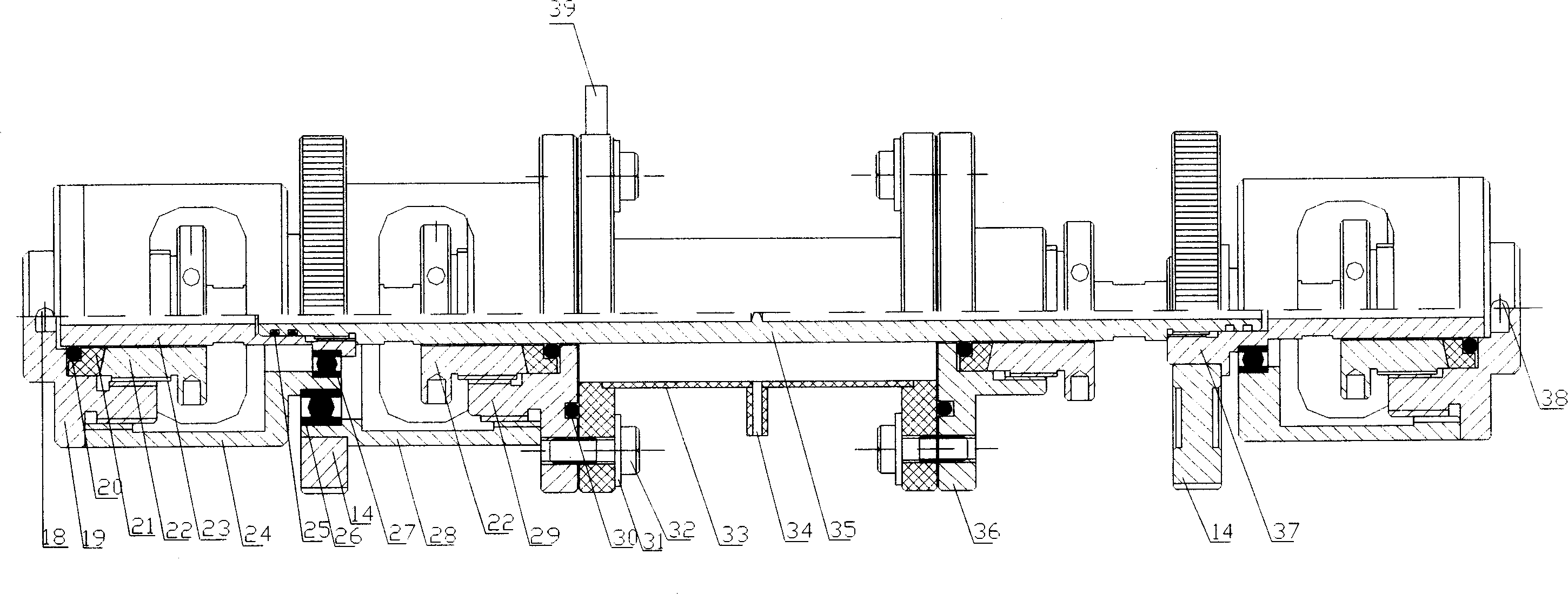

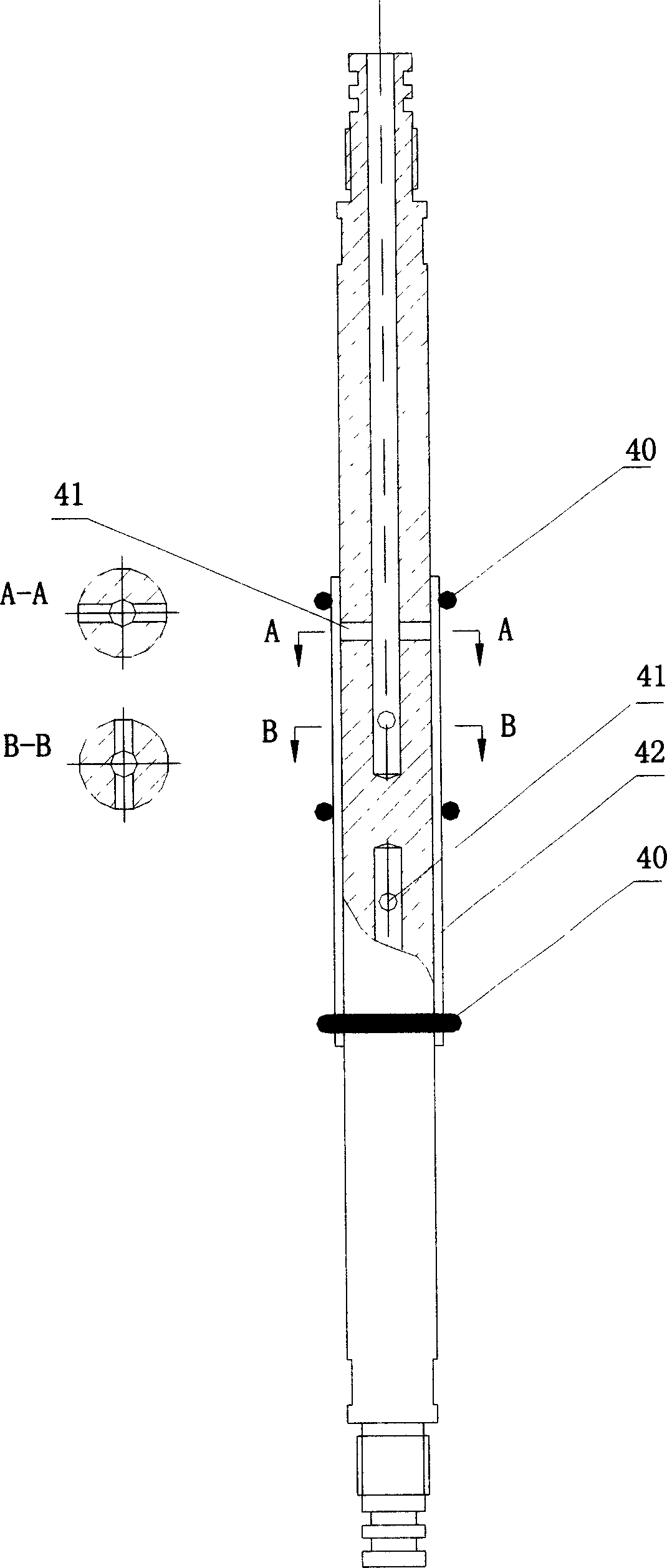

Rotary cell-culture system

A cell culture, rotary technology, applied in tissue cell/virus culture devices, biochemical instruments, biochemical equipment and methods, etc., to improve the culture effect, prevent the entry of air bubbles, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example is the result of microcarrier culture of osteoblasts in this system.

[0030] Preparation of seed cells: under aseptic conditions, take the calvaria of SD rats born 3 days old, put them into a culture dish filled with buffer solution, remove the periosteum and connective tissue, and rinse repeatedly. The washed calvaria slices were placed in a petri dish, added with 0.25% trypsin solution, and digested at a constant temperature of 37°C for 15-20min. Then the calvarial slices were digested with 1mg / ml type II collagenase solution at 37°C for 90min. Dissociate cells from bone matrix. Transfer the digestion solution to a centrifuge tube and centrifuge for 10 min (1000 rpm) to pellet the cells. The supernatant was discarded, and the precipitate was washed twice with RPMI1640 culture medium. Then pipette the bone block to obtain more osteoblasts. Repeat the centrifugation process to pellet the cells and make a cell suspension. Cells were inoculated into cul...

Embodiment 2

[0035] This example is the result of culturing hematopoietic stem cells in this system.

[0036] Preparation of umbilical cord blood hematopoietic stem cells: cord blood samples are taken from placental tissue of normal delivered full-term infants. About 60-80 ml of blood is drawn from the umbilical vein with a blood collection needle and injected into a heparin anticoagulated centrifuge tube. Then, the cord blood was evenly diluted with an equal volume of IMDM medium, centrifuged and sedimented to discard the fat-containing turbid liquid, and then diluted with IMDM. Then suck the cell suspension, carefully add it to the surface of an equal volume of lymphocyte separation solution along the tube wall, centrifuge at 1500rpm for 20min, collect the leukocyte layer, add IMDM solution for repeated washing, and then centrifuge at 1000rpm for 10min. Umbilical cord blood CD was isolated and purified by immunomagnetic strain method. 34 + Hematopoietic stem cells.

[0037] Cultured i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com