Weaving process for airbag fabriccs

A technology of fabrics and airbags, applied in fabrics, multi-strand fabrics, textiles, etc., can solve the problems of damage to fabric strength, airbags cannot be deployed, technical performance cannot meet the requirements, etc., and achieve the effect of preventing wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

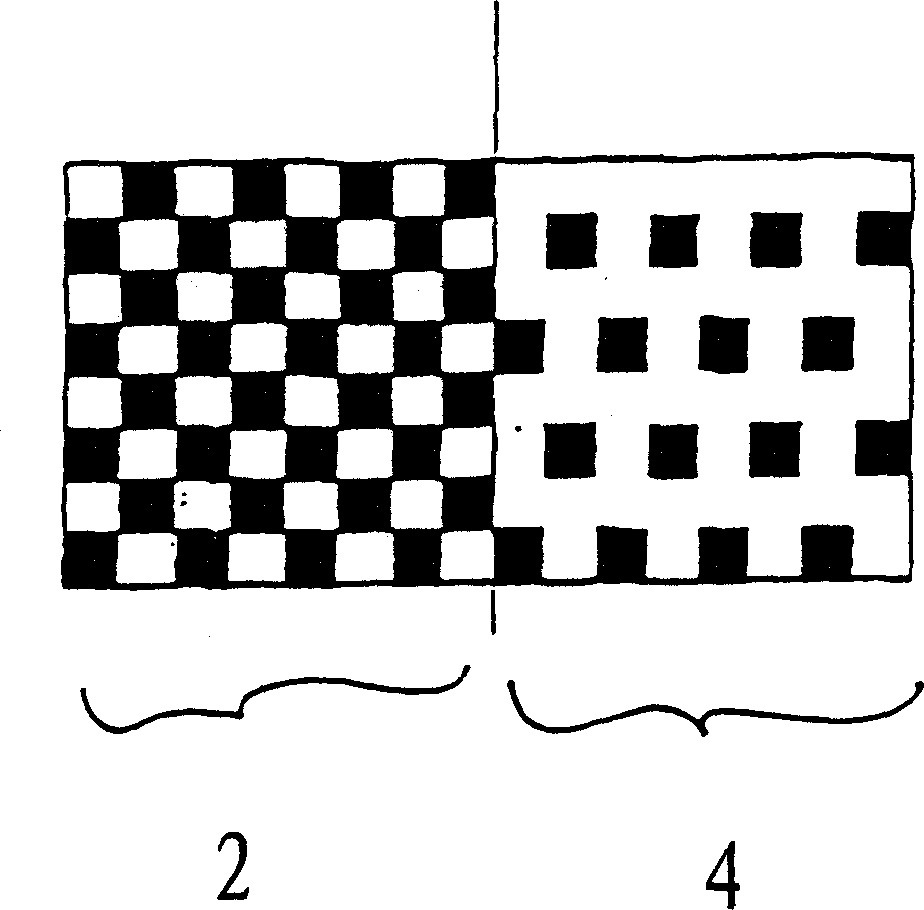

[0015] see now figure 1 , which shows the interweaving of a two-ply part 2 and a four-ply part 4 in an airbag woven by methods known in the prior art in which a plain weave is used in the two parts 2 and 4 of the fabric shown Fabric L1 / 1, due to the difference in fabric sets in the two parts of the airbag woven by this method, the finished product was severely wrinkled.

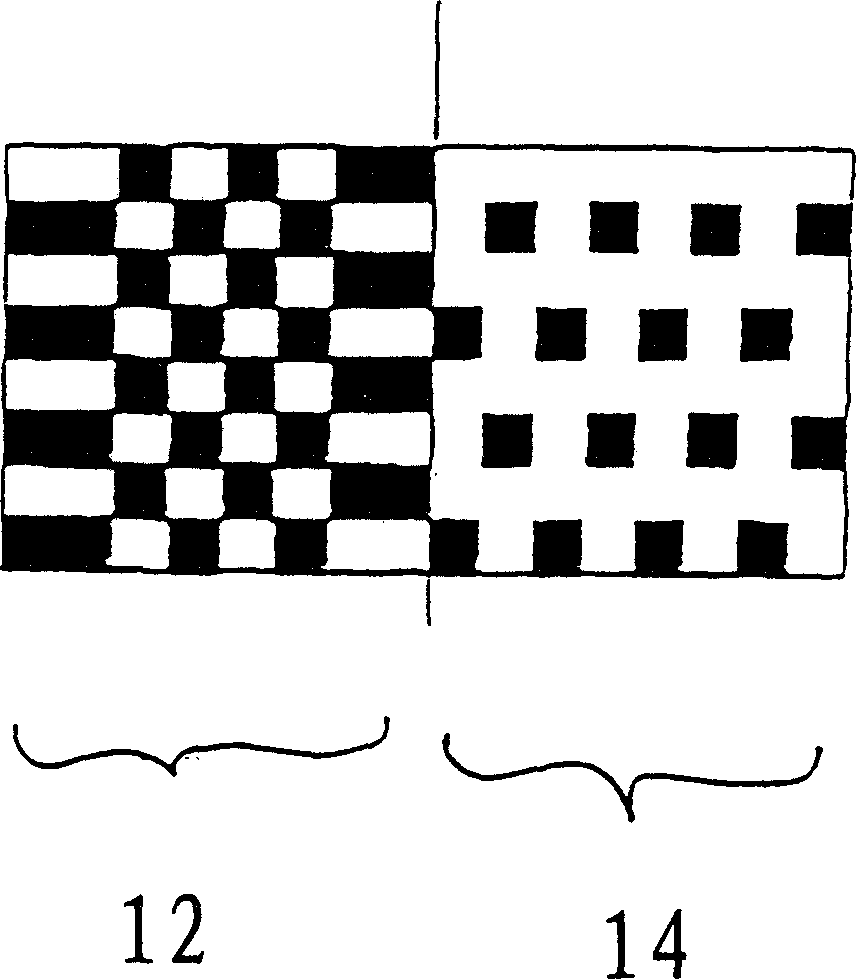

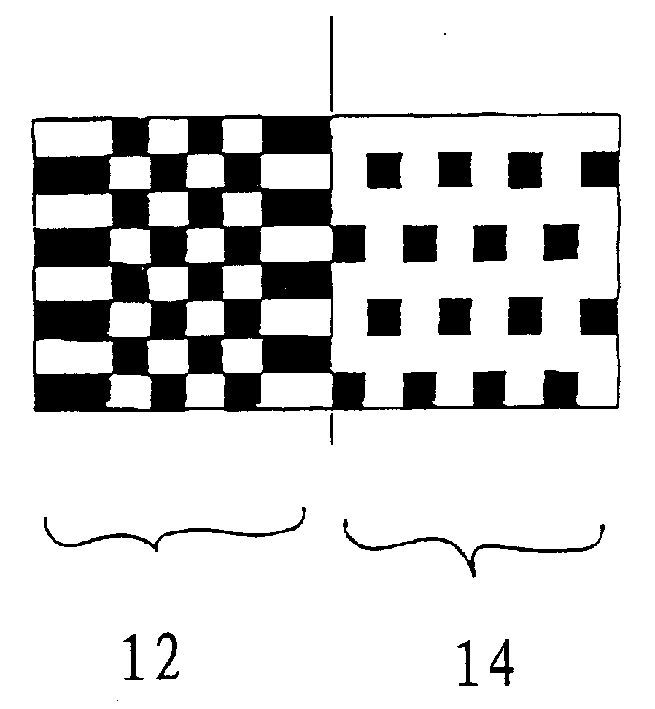

[0016] see figure 2 , showing the interweaving of two-ply parts and four-ply parts in an airbag woven according to the method of the present invention. exist figure 2 In the two-layer part 12 shown on the left of figure 2 In the four-ply part 14 shown on the right, plain weave L1 / 1 is used. Produced by applying the method of the present invention such as figure 2 The fabric shown is characterized by a uniform set obtained by reducing the set of two-ply parts 12 according to the method of the invention so as to adapt it to a set of four-ply part 14 . By utilizing the method of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com