Novel functional suspension filler

A suspended filler and functional technology, applied in the field of functional suspended filler and its production, can solve the problems of loss, fluidization difficulty, large energy, etc., and achieve strong adsorption capacity, improve removal rate, and improve oxygen transfer rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

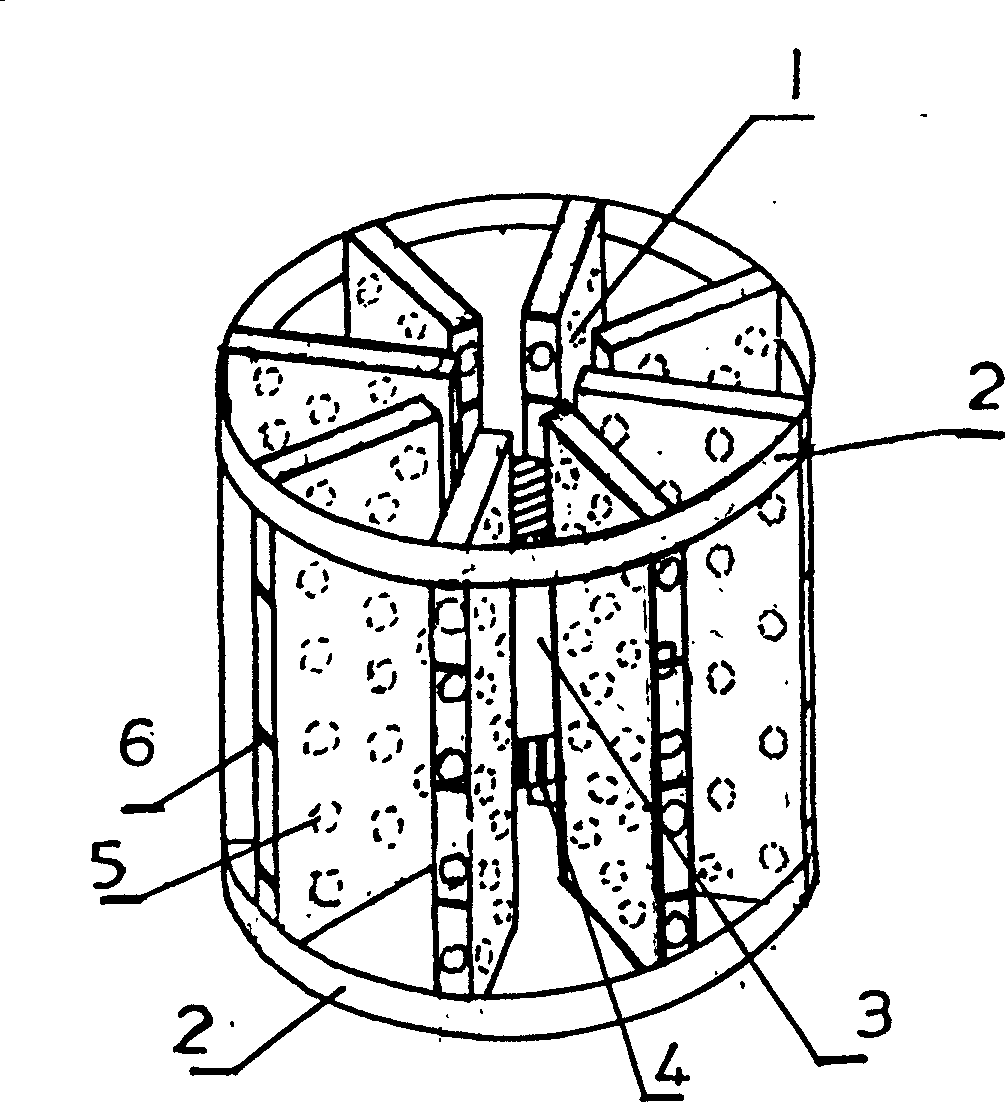

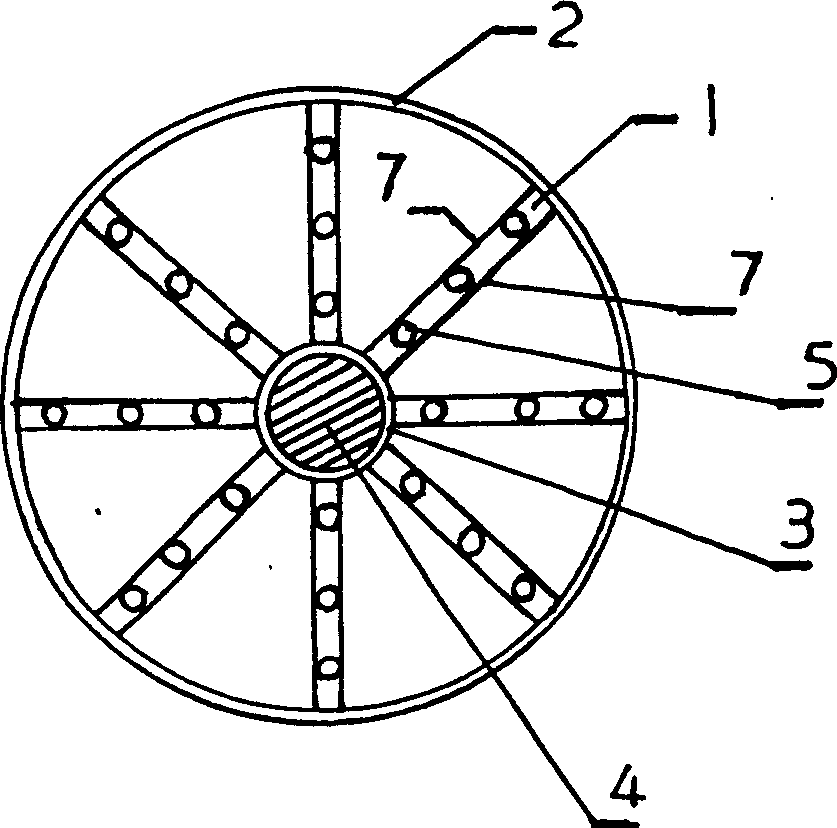

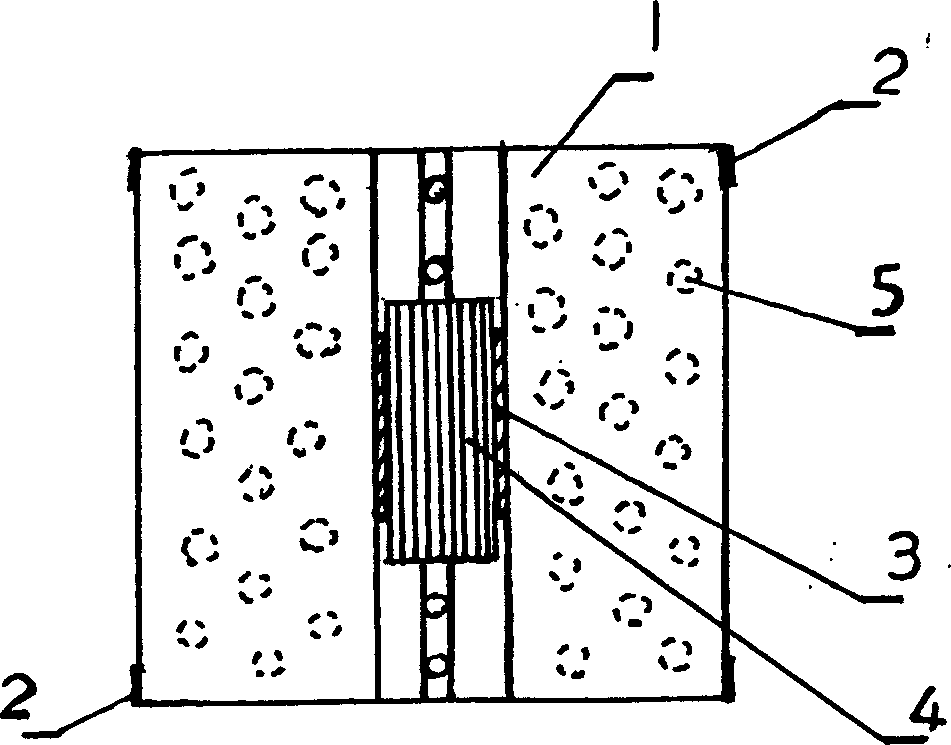

[0011] The present invention will be further described according to the above-mentioned accompanying drawings. The invention is composed of a composite wing plate 1, a fixed ring 2, an intermediate fixed ring 3, a water-repellent foam plastic 4 and a granular zeolite (molecular sieve) 5. The composite wing plate 1 is composed of granular molecular sieve material 5 arranged between two plastic plates 7, and the two plastic plates 7 are fixedly connected by fixing strips 6 arranged on the sides, so that the granular zeolite material 5 is firmly clamped between the plastic plates 7 without making them move. The middle part of the inner side of the composite wing plate 1 is fixedly connected with the middle fixed ring 3, and the upper and lower parts of the outer side are firmly fixedly connected with the fixed ring 2 to form a whole. In the middle fixed ring 3, a water-repellent foam plastic 4 is set according to the sewage condition. The specific gravity of the suspended filler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com