Button switches

A switch and button technology, applied in the field of structure, can solve problems such as poor contact, lack of operation feeling, and affecting operation feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

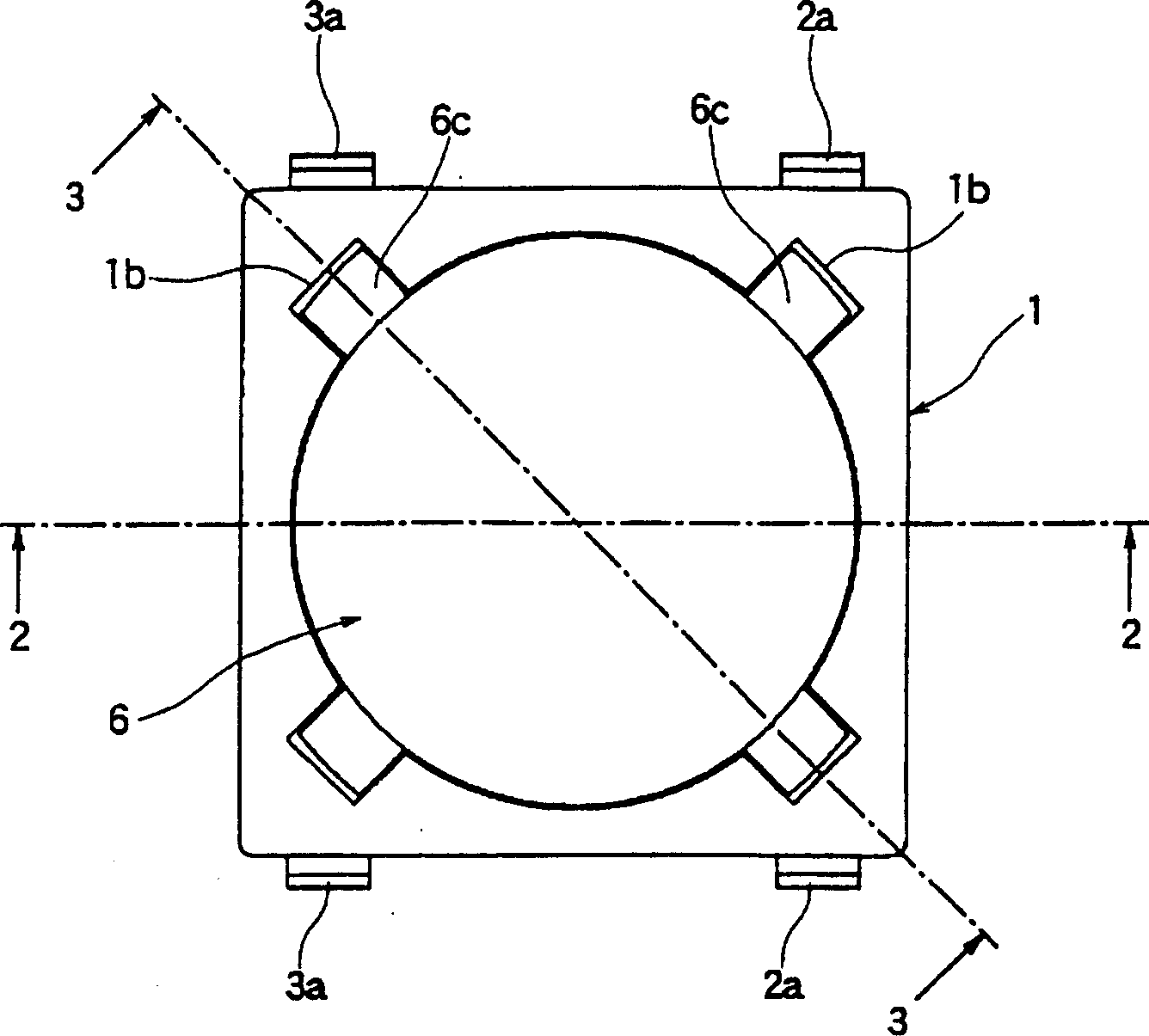

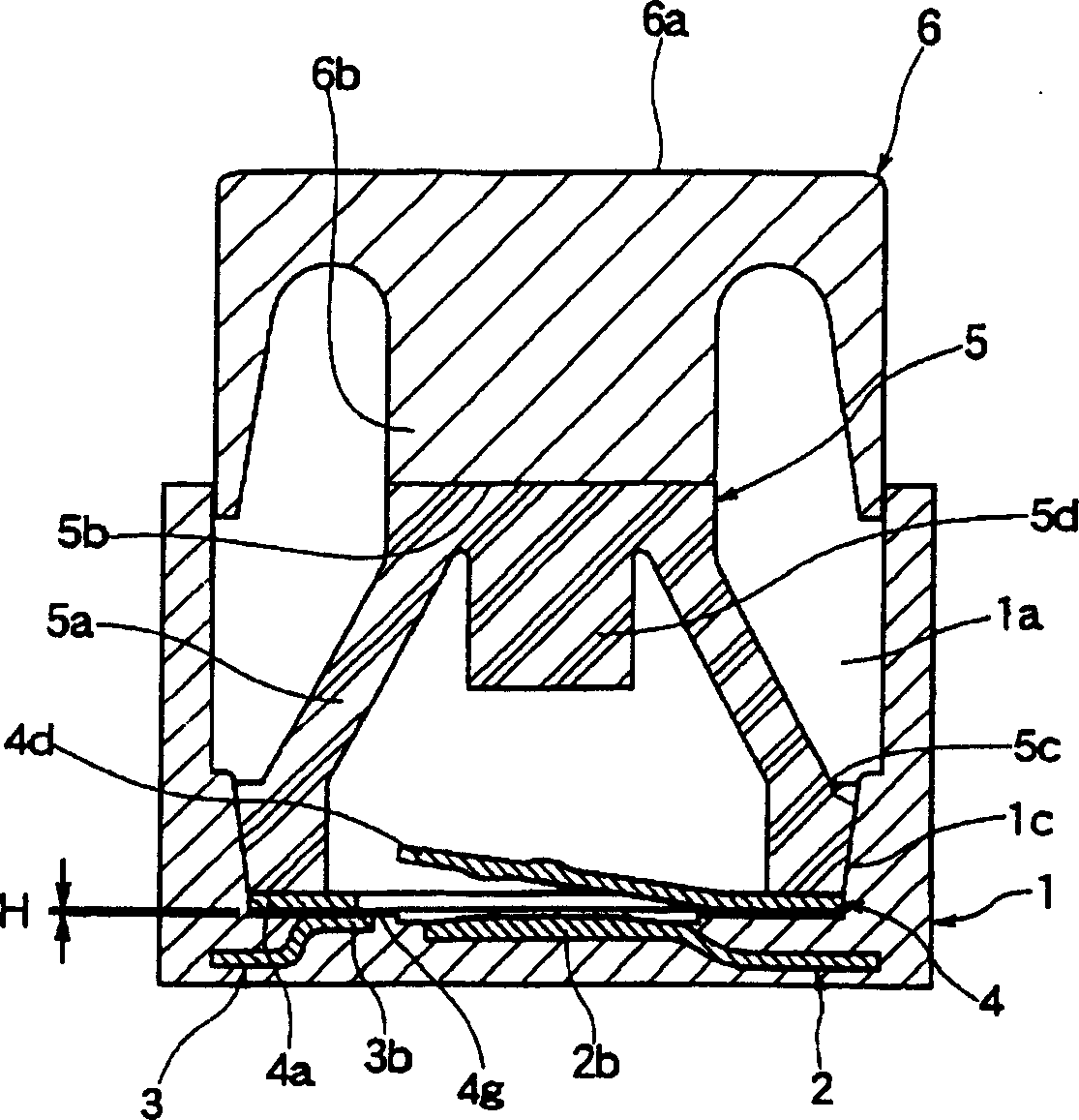

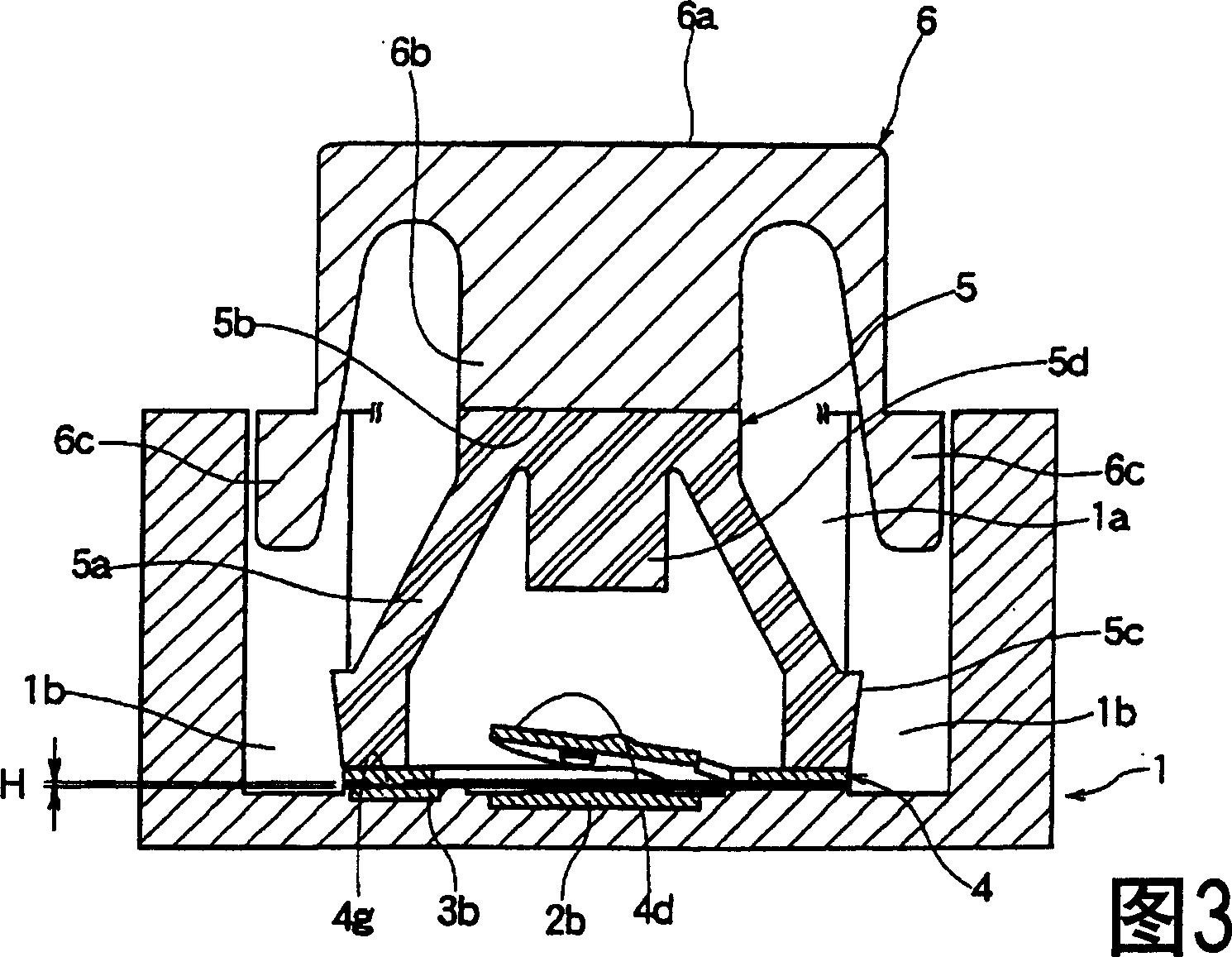

[0039] the following in Figure 1 to Figure 9 An embodiment of the push button switch of the present invention is shown in . figure 1 is the top view of the push button switch, figure 2 is along figure 1 The sectional view of line 2-2 in Figure 3 is along the figure 1 sectional view of the 3-3 line, Figure 4 is the top view of the shell, Figure 5 is the top view of the rubber spring, Image 6 is a sectional view of the rubber spring, Figure 7 is a top view of the movable contact, Figure 8 It is a sectional view of the movable contact. Figure 9 It is an explanatory diagram showing the dynamic force characteristic of the rubber spring.

[0040] The housing 1 is made of an insulating material such as synthetic resin into a rectangular box shape with an open top. A receiving portion 1a is formed in the opening of the housing 1, and a pair of fixed contacts 2, 3 formed of conductive metal materials such as brass are provided on the inner bottom of the receiving po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com