Phased array probe for scanning imager

A phased array probe and scanning imaging technology, applied in the field of phased array probes, can solve problems such as limitations, low efficiency, and the inability of the probe to directly emit shear waves, and achieve the effect of avoiding energy loss or other interference and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] like figure 1 As shown, 8 transducer units 2 are spaced in parallel along the width direction to form a linear array, and the distance between adjacent transducer units 2 is 0.1 mm; this array is embedded in the support structure 1, and the support structure is epoxy Resin material.

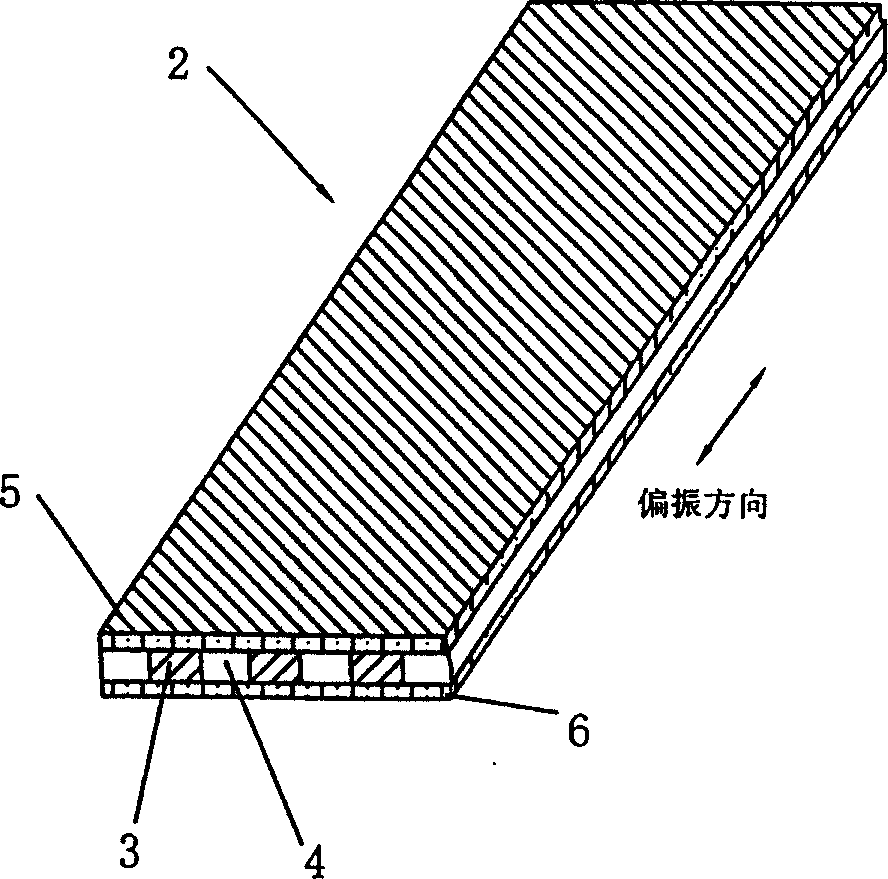

[0021] The structure of the transducer unit 2 is as figure 2 As shown, it is substantially cuboid, and its width is 0.8 millimeters, and thickness is 1.1 millimeters, and length is 10 millimeters, and the wavelength of this transducer unit 2 emitting sound waves is 3 millimeters (corresponding to the situation that detection body is metallic steel), In its width direction, there are 3 strip-shaped piezoelectric blocks 3 and 4 non-piezoelectric blocks 4 alternately placed; the polarization direction of the piezoelectric blocks 3 is along the length directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com