Alcohol liquid waste treating method for sugar refinery

A technology of waste alcohol mash and treatment method, which is applied to the comprehensive treatment field of "three wastes" in sugar factories, can solve the problems of high operating cost, large investment, secondary pollution, etc., and achieves high total number of viable bacteria, pollution control, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

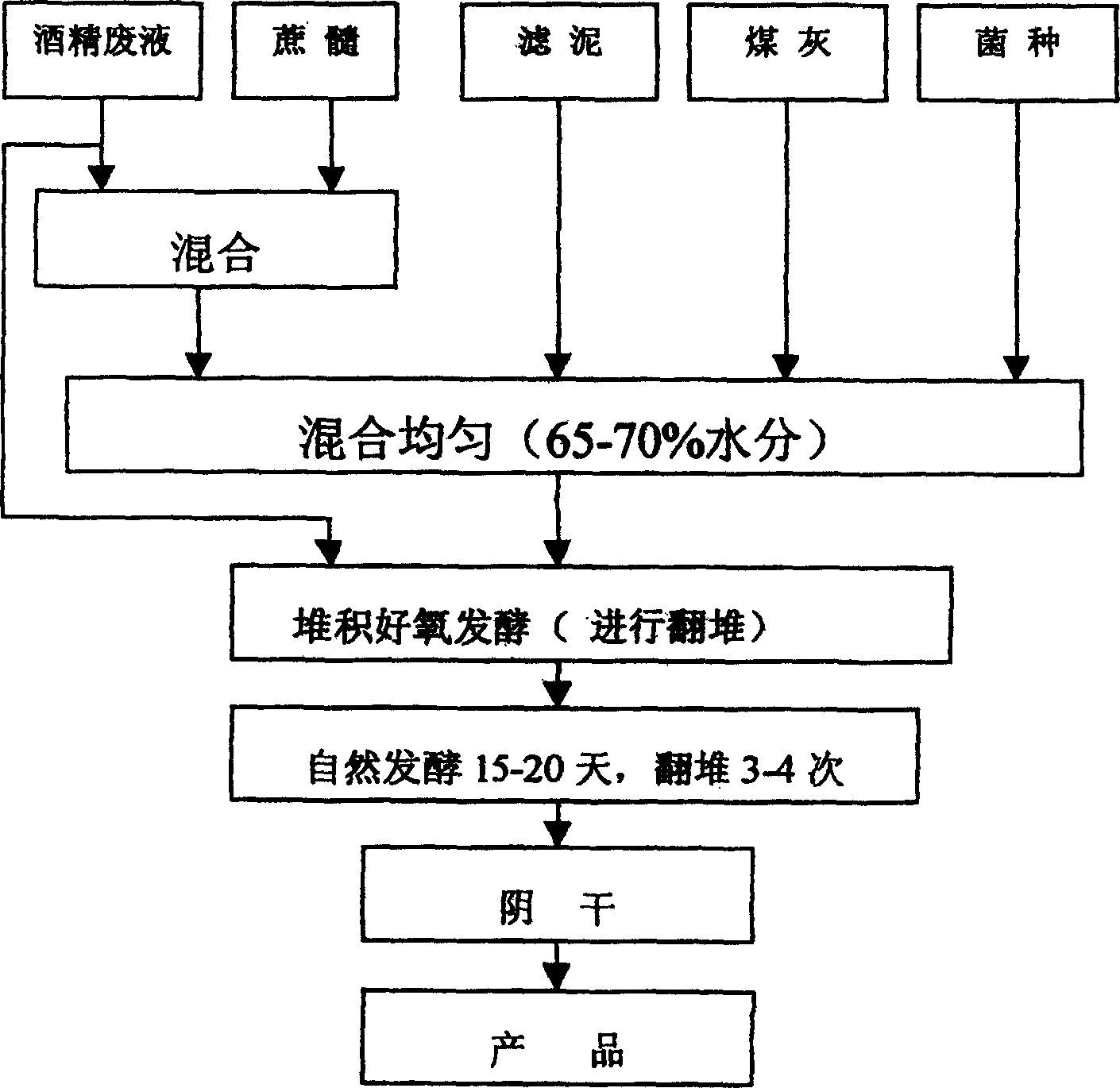

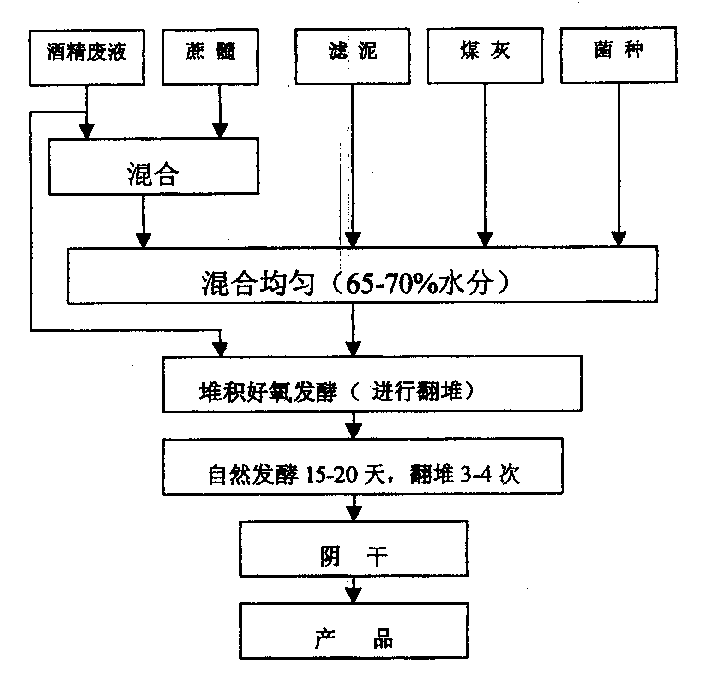

[0009] see figure 1 , mix alcohol waste mash with sugarcane pith, then add filter mud, coal ash and compound strains composed of yeast, bacteria, and actinomycetes to mix together. The mixing ratio of each component is 35% to 45% of sugarcane pith %, 35% to 40% of filter mud, 15% to 25% of coal ash, 3‰ to 8‰ of composite bacteria, and the balance is alcohol waste mash. The amount of alcohol waste mash is added to keep the material moisture from 65% to 70% is better, and the temperature when the alcohol waste mash is added is below 40°C, and then stacked and fermented, the temperature during fermentation is 55°C to 65°C, and the fermentation time is 15 days to 20 days. The filter mud for the above-mentioned preparation of solid fertilizer adopts the sugar factory sub-method filter mud, air-dried to less than 50% moisture, coal ash air-dried to less than 40% moisture, when fermenting, the material should be turned over every 3 to 4 days, so that The temperature of each part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com