Torque and load sensor

A technology of load sensors and mechanical parts, applied in the field of mechanical measurement sensors, can solve the problem of not being able to detect torque and tension at the same time, and achieve the effect of accurate output signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

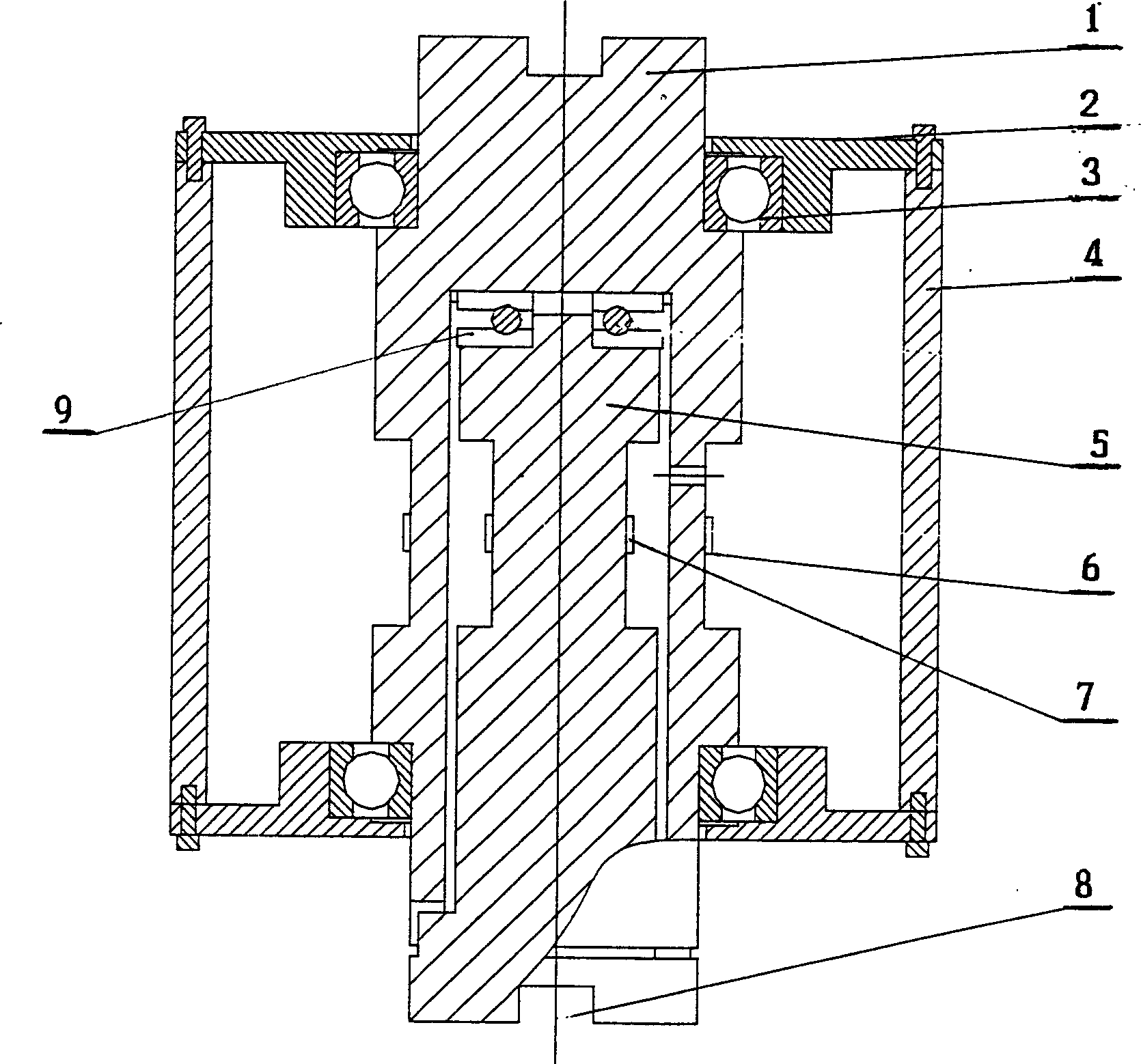

Embodiment 1

[0022] Embodiment 1: internal pressure and external torsion type torque, load sensor, the shell (4) is cylindrical, and external diameter is 250 millimeters, and length is 280 millimeters. There are end covers (2) at both ends of the casing (4), and bearings (3) are respectively fixed on the end covers (2). There is a hole in the middle of the outer shaft (1), and the inner shaft (5) is sleeved in the hole of the outer shaft (1). A thrust bearing (9) is arranged between the inner shaft (5) and the outer shaft (1). The thrust bearing (9) is between the end of the inner shaft (5) and the bottom of the bore of the outer shaft (1). A shaft coupling groove (8) is respectively arranged at the upper end of the outer shaft (1) and the lower end of the inner shaft (5), which are used to connect with the parts to be detected when the sensor is installed. The torque borne by the outer shaft (1) cannot be transmitted to the inner shaft (5) through the thrust bearing (9); the pressure bo...

Embodiment 2

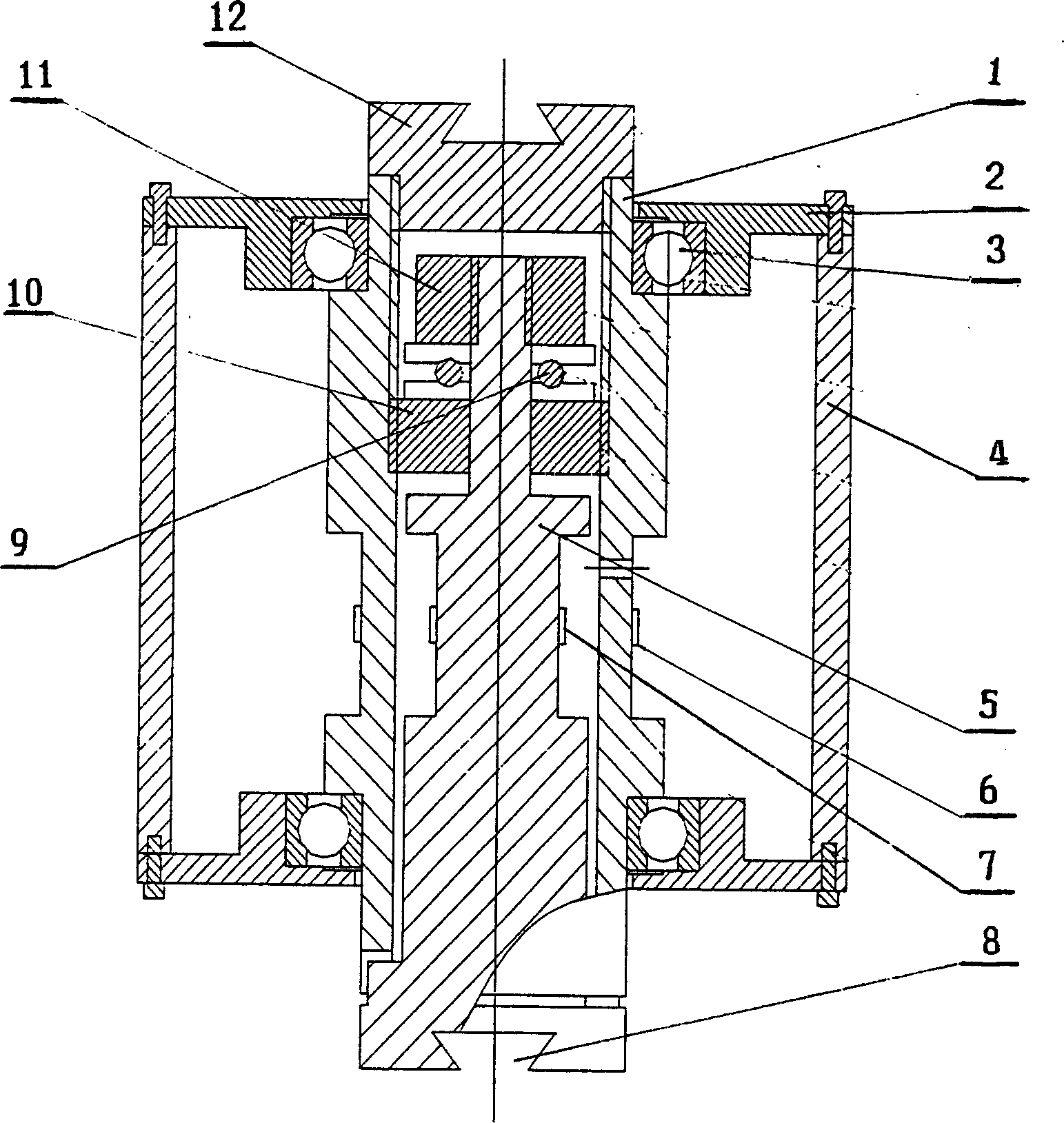

[0023] Embodiment 2: internal pull external torsion type torque, load sensor. Shell (4) is identical with embodiment 1, and its encasement structure is that the shaft (5) that is pasted with tensile resistance strain gauge (7) is inside, and the shaft (1) that is pasted with torque resistance strain gauge (6) is outside. There is a lock nut (11) at the end of the inner shaft (5). A thrust bearing (9) is arranged between the lock nut (11) and the retaining ring (10). Backstop ring (10) is threaded connection with outer shaft (1). Outer shaft (1) end has connecting shaft head (12), and connecting shaft head (12) top has dovetail groove (8), and its bottom is threadedly connected with outer shaft (1). A dovetail groove (8) is arranged at the lower end of the inner shaft (5). The dovetail groove (8) is to connect the components to be detected. The external tension on the outer shaft (1) is transmitted to the inner shaft (5) through the retaining ring (10), the thrust bearing (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com