Bolt and method for forming protective layer on bolt

A bolt and thread technology, applied in the field of bolts, can solve the problems of sufficient coverage of bolts, uneven thickness of the protective layer, and waste products, etc., and achieve the effect of reducing the bite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

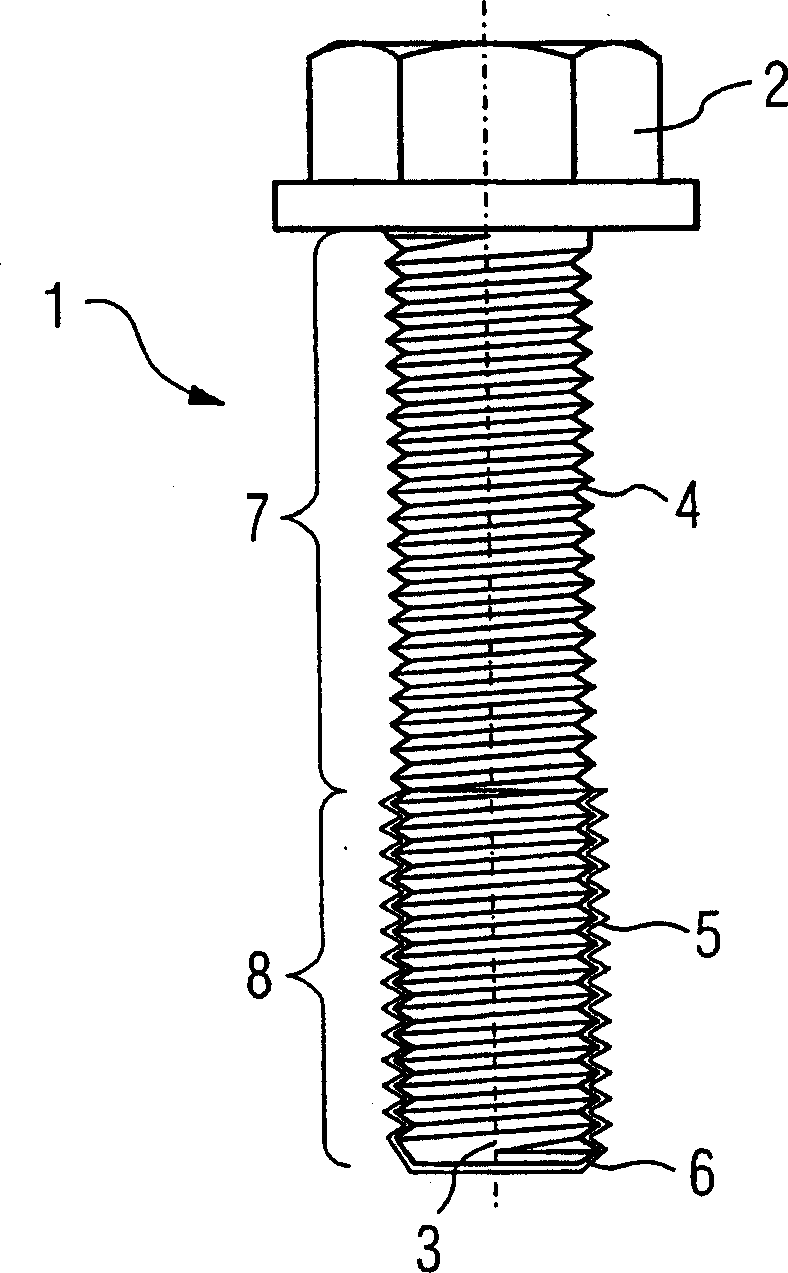

[0021] figure 1 A coated bolt 1 can be seen in . It has a screw head 2 and a threaded section 4 extending along a longitudinal axis 3 . In the illustrated embodiment, the thread section 4 extends from the head 2 to the thread start point 6 . Along its longitudinal axis 3 , the screw 1 has an upper thread section 7 and a lower thread section 8 , wherein the division between the two upper and lower thread sections 7 and 8 can be varied as desired. The screw 1 is also possible in other embodiments, for example the screw 1 has a threaded section 4 along the longitudinal axis 3 which is only partially coated with high-temperature paint. The bolt can be produced, for example, from 12% chrome steel.

[0022] The screw 1 can also be used in steam turbines and gas turbines.

[0023] The screw 1 is coated over its entire threaded section 4 with an aluminum-containing high-temperature paint 5 . The aluminum-containing high-temperature varnish does not have to be applied over the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com