No-baking brick made of oil field sludge and its production process

An oilfield sludge and production method technology, which is applied to manufacturing tools, ceramic molding machines, and solid waste removal, etc., can solve the problem of not meeting the requirements of ecological building materials, the curing strength not meeting the requirements of building bricks, and the alkalinity radioactivity test. Non-compliance with building materials standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

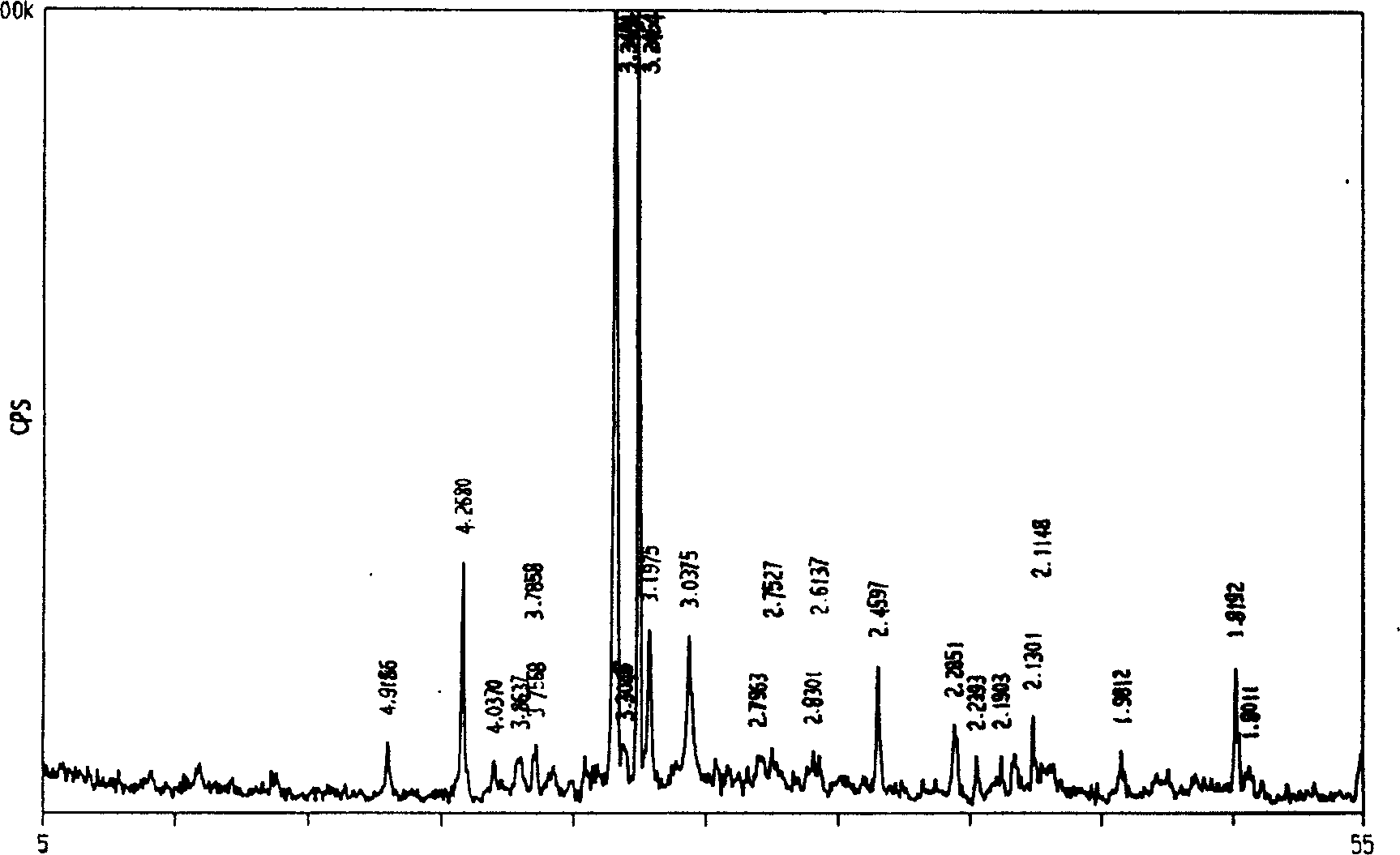

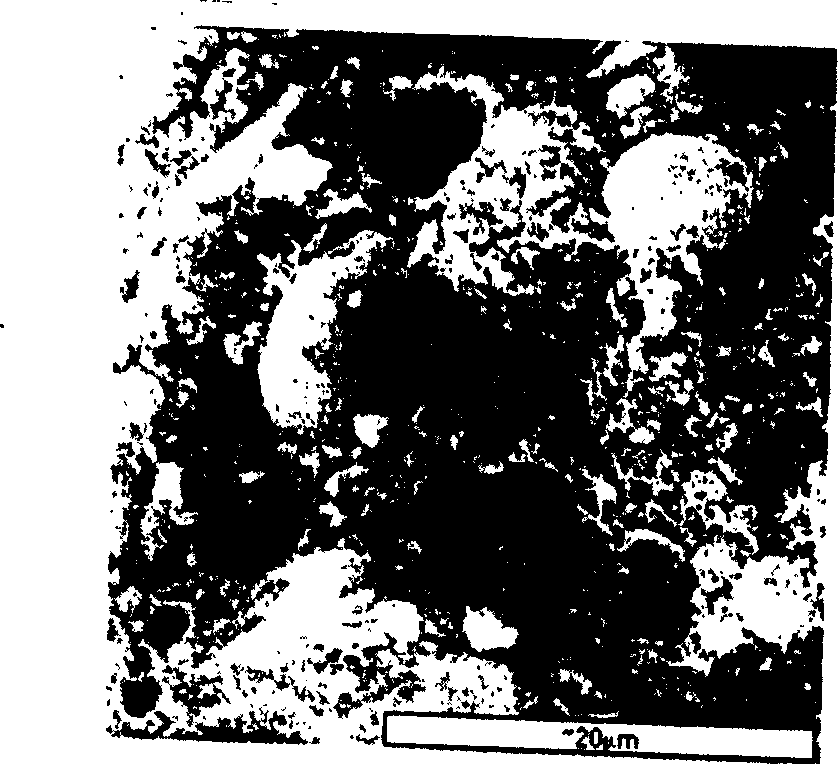

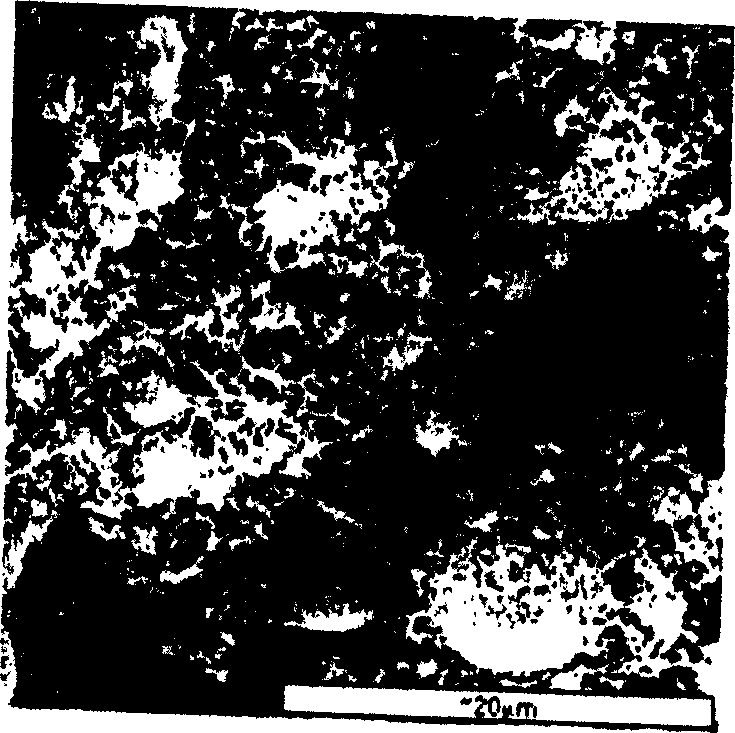

Image

Examples

Embodiment 1

[0060] The ratio of raw materials in this embodiment is 30% of oilfield sludge, 40% of river sand, 26% of cement, and 4% of curing agent.

[0061] Wherein, the curing agent is mixed with the raw materials in the following weight ratio:

[0062] Sulfoaluminate: 22% Calcium Stearate: 5%

[0063] Calcium Chloride: 20% Calcium Acetate: 0

[0064] Fluorite: 0 Gelatin: 5%

[0066] Acrylic resin 0

[0067] Core material: 10%

[0068] CaO

MgO

Fe 2 o 3

SiO 2

Al 2 o 3

Al 2 (SO 4 ) 4

Na 2 CO 3

FeSO 4

MgSO 4

10

8

10

8

10

5

12

19

18

[0069] The production method is:

[0070] After mixing oilfield sludge, river sand, cement, and curing agent evenly, put the slurry material into a mold, apply a pressure of 550KN on a press to form, demould, and dry to make a finished product.

[0071] According to the buildin...

Embodiment 2

[0080] The ratio of raw materials in this embodiment is 35% of oilfield sludge, 20% of river sand, 20% of cement, 24% of fly ash, and 1% of curing agent.

[0081] Wherein, the curing agent is mixed with the raw materials in the following weight ratio:

[0082] Sulfoaluminate: 15% Calcium Stearate: 2%

[0083] Calcium Chloride: 10% Calcium Acetate: 15%

[0084] Fluorite: 10% Gelatin: 9%

[0086] Acrylic 4%

[0087] After oilfield sludge, river sand, cement, fly ash, and curing agent are mixed evenly, the slurry material is loaded into a mold, pressed on a press with a pressure of 650KN, demolded, and dried to make a finished product.

[0088] The performance test results are: the average 28-day compressive strength is 16.66Mpa, and the 28-day flexural strength is 5.65Mpa. Its mechanical properties can still meet the relevant national standards. Other properties are substantially the same as in Example 1.

Embodiment 3

[0090] The ratio of raw materials in this embodiment is 55% of oilfield sludge, 20% of river sand, 18% of cement, and 7% of curing agent.

[0091] Wherein, the proportioning of curing agent is:

[0092] Sulfoaluminate: 20% Calcium Stearate: 5%

[0093] Calcium Chloride: 15% Calcium Acetate: 10%

[0094] Fluorite: 0 Gelatin: 5%

[0096] Acrylic resin 0 Monoethylene glycol 5%

[0097] Sucrose 5%

[0098] Core material: 10%

[0099] Wherein the core material is composed of the following raw materials in weight percentage: CaO MgO Fe 2 o 3 SiO 2 al 2 o 3 al 2 (SO 4 ) 4 Na 2 CO 3 FeSO 4 MgSO 4 5 5 6 15 12 20 20 7 10

[0100] The production method is as follows: After mixing oilfield sludge, river sand, cement, fly ash, and curing agent evenly, the slurry material is loaded into a mold, pressed on a press with a pressure of 650KN, demolded, and dried to make a finished product .

[0101] The performance test results are: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com