Separation method for plasma protein

A separation method and plasma protein technology, which are applied in the preparation methods of peptides, albumin peptides, chemical instruments and methods, etc., can solve problems such as unfavorable pipeline and automatic control, affecting product quality and yield, personnel and product contamination, etc. , to achieve the effect of improving the production environment, reducing equipment investment and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

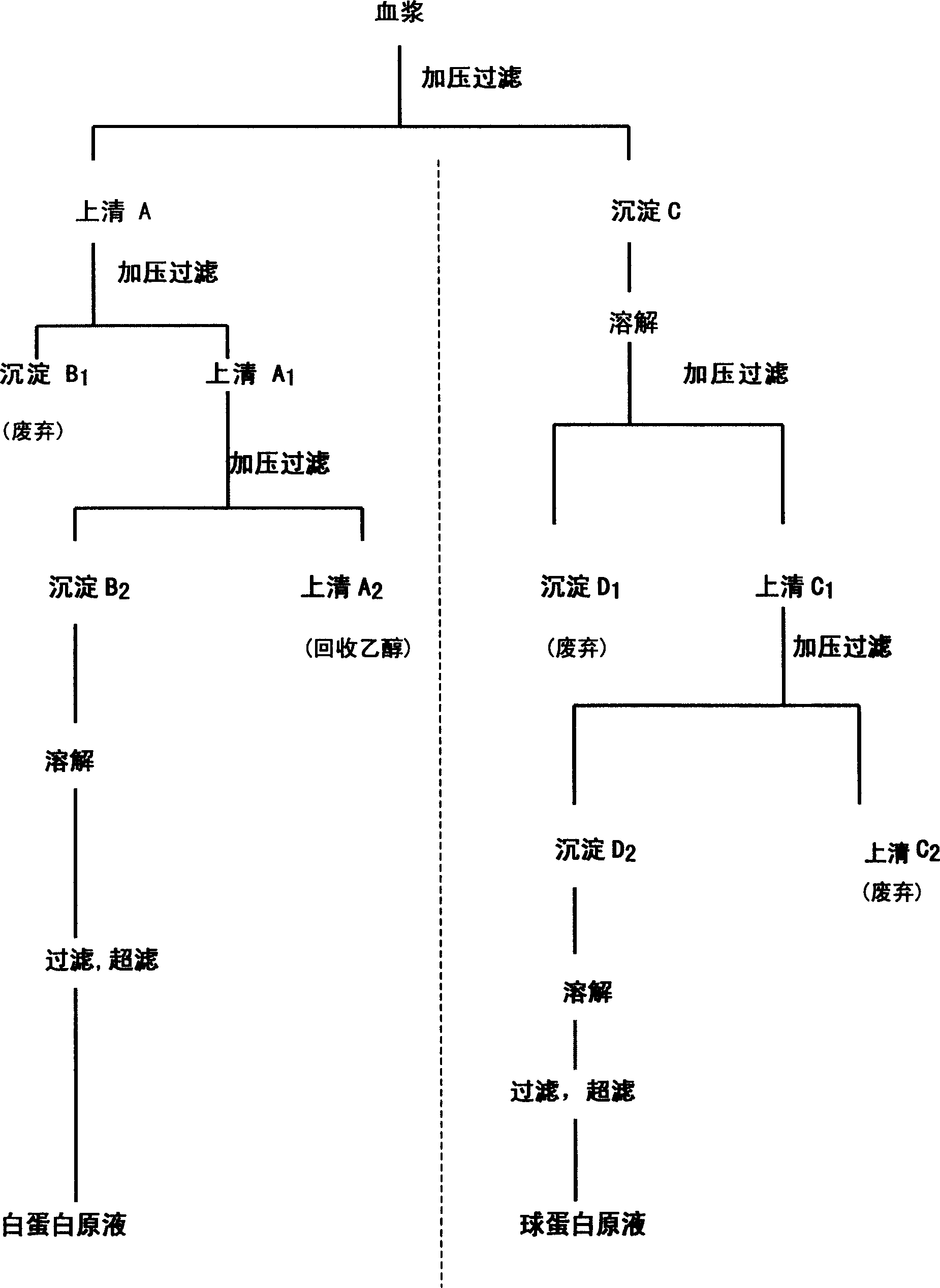

[0052] (1) Take 1,000 parts of blood plasma that have passed the test and mix them according to the figure 1 The steps shown are separated step by step, through the following steps:

[0053] a. Frozen plasma is melted in a slurry tank, the temperature of the slurry is 30-37°C, and it is stirred continuously until it is completely melted; enter the interlayer reaction tank, and adjust the following parameters under stirring conditions: adjust the pH with acetate buffer: 5.81 (Change to 5.9), adjust the protein concentration (P%) with water for injection: 5.28%, adjust r / 2: 0.14 with sodium chloride, T:-4 ° C, adjust the solution EtOH concentration with 95% ethanol to be: 20%.

[0054] Then, add 0.31 grams of diatomaceous earth per liter of blood plasma, stir at 20-60 rpm for 60 minutes, and then filter the solution into a filter press: pressure 0-3bars, filter plate 10 square meters, filter plate pore size 0.45 Micron. Press filtration to separate the supernatant and precipit...

Embodiment 2

[0066] (1) Take 1,000 parts of blood plasma that have passed the test and mix them according to the figure 1 The steps shown are separated step by step, through the following steps:

[0067] a. Frozen plasma is melted in a slurry tank, the temperature of the slurry is 30-37°C, and it is stirred continuously until it is completely melted; enter the interlayer reaction tank, and adjust the following parameters under stirring conditions: adjust the pH with acetate buffer: 6.1 , adjust protein concentration (P%) with water for injection: 5.28%, adjust r / 2: 0.14 with sodium chloride, T: -6°C, adjust solution EtOH concentration with 95% ethanol: 20%.

[0068] Then, add 0.66 grams of diatomaceous earth per liter of plasma, stir at 20-60 rpm for 30 minutes, and then enter the filter press for filtration: pressure 0-3bars, filter plate 12 square meters, filter plate pore size 0.65 microns , press filtration to separate the precipitate and supernatant;

[0069] b. The supernatant obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com