Testing method for elastic modulus of air-conditioned compressor electric machine rotor

An air-conditioning compressor, elastic modulus technology, applied in the direction of measuring device, strength characteristics, material analysis by electromagnetic means, etc., can solve the problems of small overall deformation, sensor measurement of overall deformation, etc., to achieve the effect of solving test problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now, the present invention will be further described in conjunction with an embodiment and accompanying drawings.

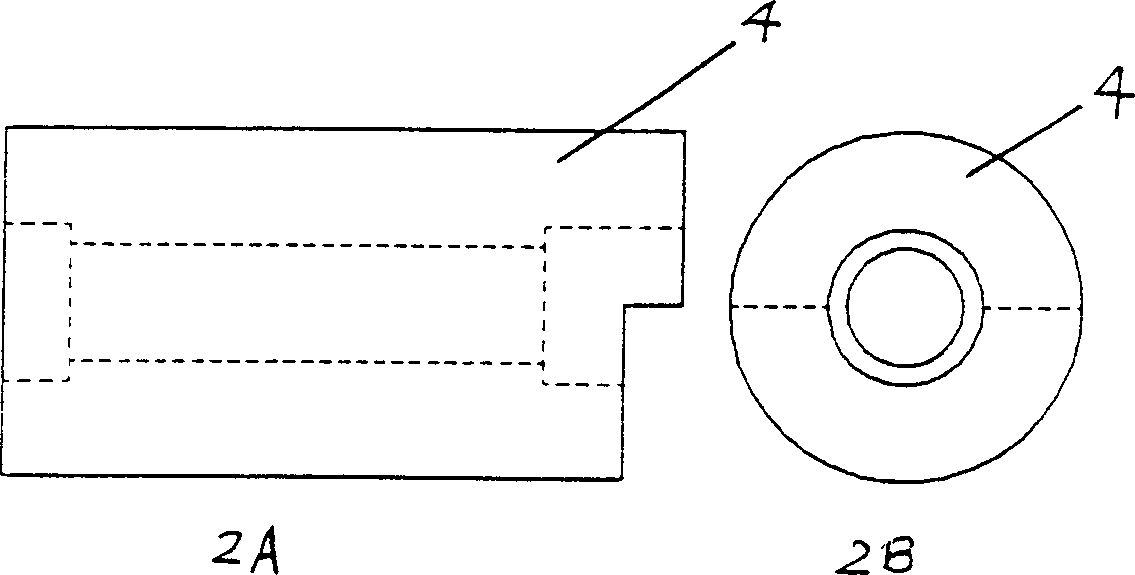

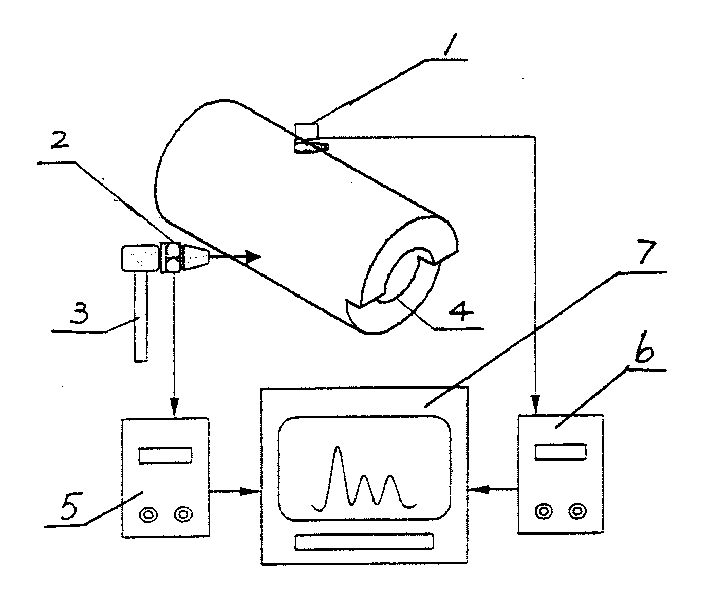

[0030] ●Firstly, connect the B&K4374 acceleration sensor with the B&K2635 charge amplifier as required by wires, and connect the charge amplifier with the CF-350 spectrum analyzer; install the B&K8200 force sensor on the hammer, and use the wires to connect the force sensor with another B&K2635 The charge amplifier is connected, and then the charge amplifier is connected with the CF-350 spectrum analyzer, such as figure 1 shown.

[0031] The force sensor (B&K8200) and the acceleration sensor (B&K4374) are sensors made of the piezoelectric effect of the crystal, and the output charge is proportional to the force or acceleration on the test piece; the output voltage of the charge amplifier (B&K2635) It is proportional to the amount of input charge; the spectrum analyzer (CF-350) is a dual-channel spectrum analyzer, which performs signal processing such as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com