Laer moudle

A laser module and laser component technology, which is applied to lasers, laser parts, semiconductor lasers, etc., can solve the problems of polluting the inside of the module, easy breakage of optical fibers, and low practicability, so as to simplify the manufacturing process, suppress dust collection, and prevent dust collection. dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the present invention will be described in detail below using the drawings.

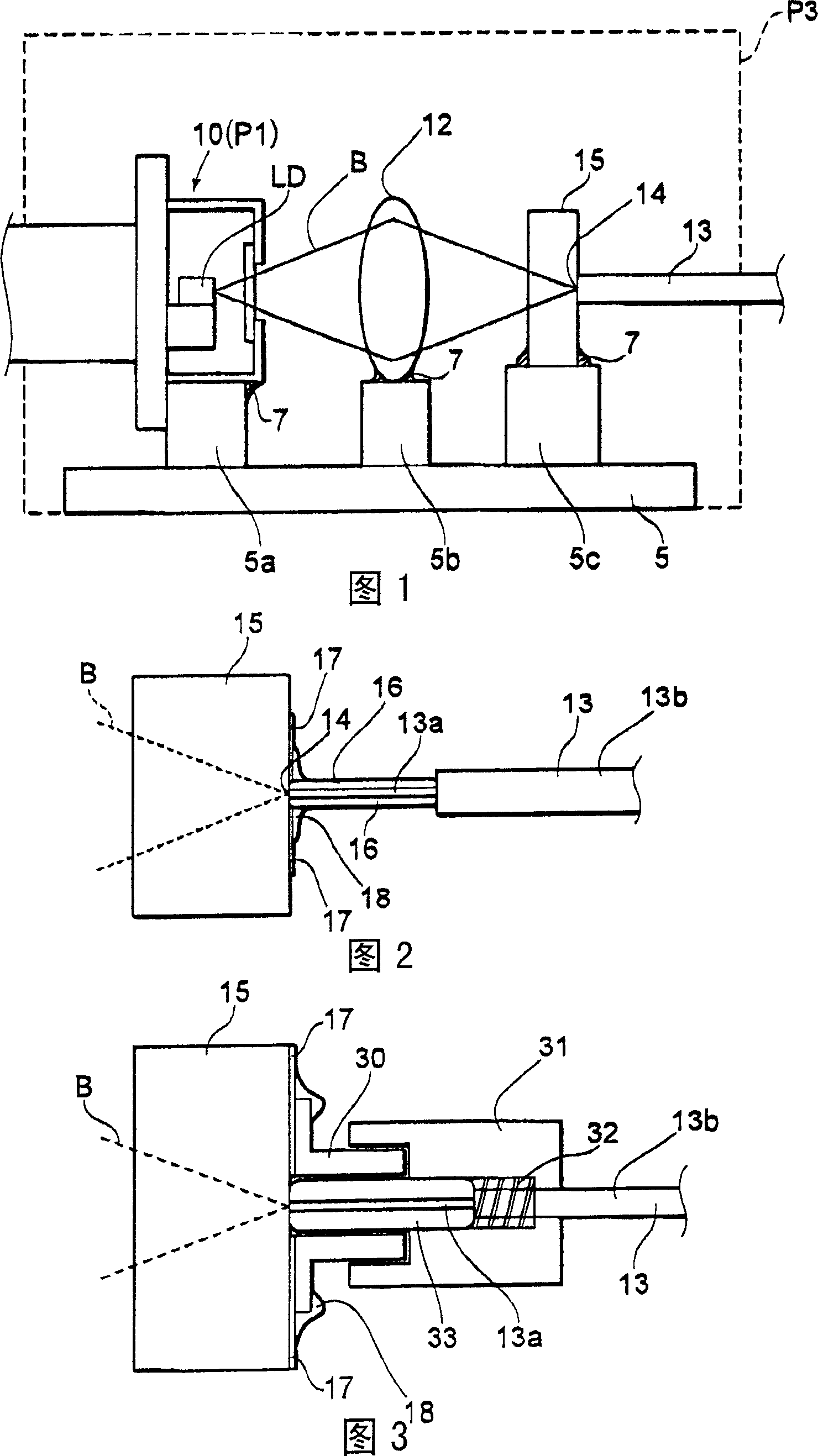

[0057] First, a laser module according to a first embodiment of the present invention will be described. Fig. 1 is a side view showing its schematic structure.

[0058] The laser module of this embodiment includes a semiconductor laser element LD inside, and is composed of a hermetically sealed CAN assembly 10, a condenser lens 12, an optical fiber 13, and a rectangular parallelepiped glass block 15 welded to the incident end face 14 of the optical fiber 13. In this embodiment, the CAN module 10 is the first module P1, and the glass block 15 welded to the incident end surface 14 of the optical fiber 13 is the incident end surface protection member.

[0059] CAN assembly 10, condensing lens 12 and the glass block 15 configuration that comprises optical fiber 13 are fixed on each fixed part 5a on the common base plate 5, on 5b and 5c, make the laser beam B that emits from semicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com