Rear plate assembly of disc brake block

A disc brake, disc brake technology, applied in the direction of brake components, brake types, bicycle brakes, etc., can solve the problems of increasing the risk of noise and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

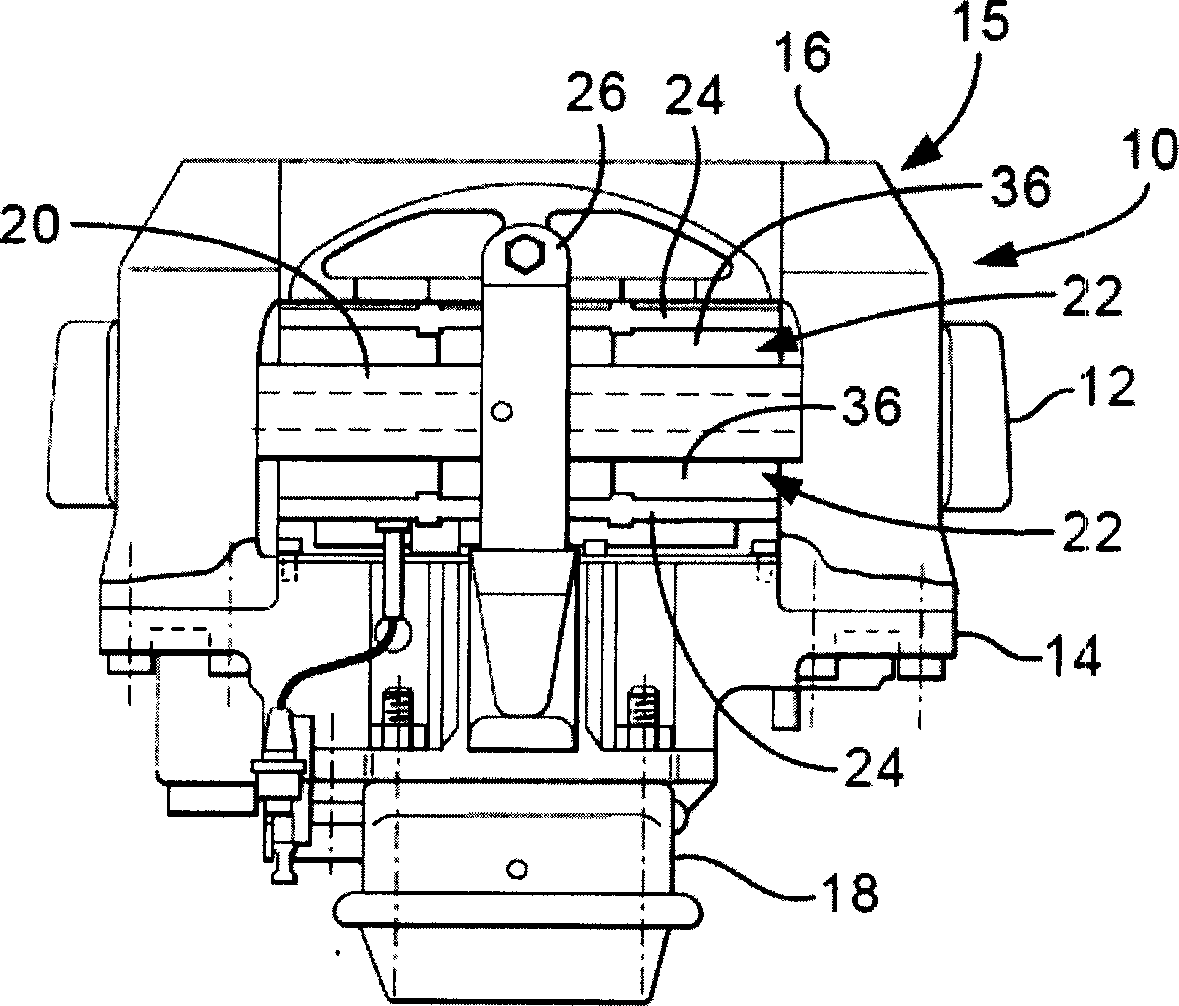

[0019] Figure 4 and FIG. 5 shows a disc brake pad rear plate assembly 133 according to one embodiment of the present invention. Assembly 133 can be adapted to the prior art disc brake 10 described above. Assembly 133 includes rear plate 134 to which friction material (not shown) is secured. The rear plate includes a pair of circumferentially spaced abutments 140 on a radially outer face 135 . Leaf spring retention means such as a pair of radially outward lugs 150 also protrude from the radially outer face 135 of the rear plate 134 and are positioned between the standoffs 140 .

[0020] from Figure 4 It can be seen that the leaf spring 124 is an elongated strip having a middle region 148 and an end region 149 . When the leaf spring 124 is mounted to the rear plate 134 , the leaf spring 124 in use extends in a circumferential direction across the axis of motion YY of the rear plate 134 , which moves back and forth relative to the rotor 20 . The leaf spring is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com