Column pile and sheet pile joined body construction method and its special equipment

A technology of special equipment and construction methods, applied in sheet pile walls, artificial islands, water conservancy projects, etc., can solve the problems of inconvenient construction of precast concrete sheet piles, high cost of steel sheet pile hammering, and poor anti-seepage effect. Simple structure, low cost and good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

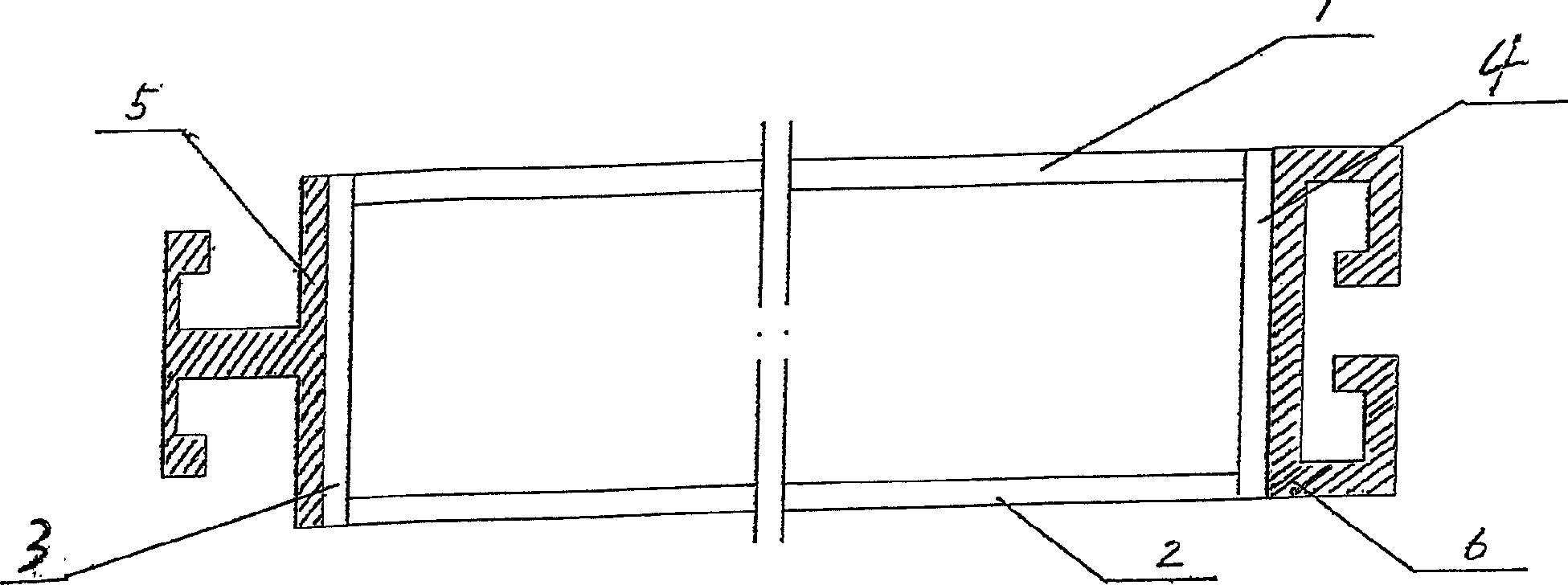

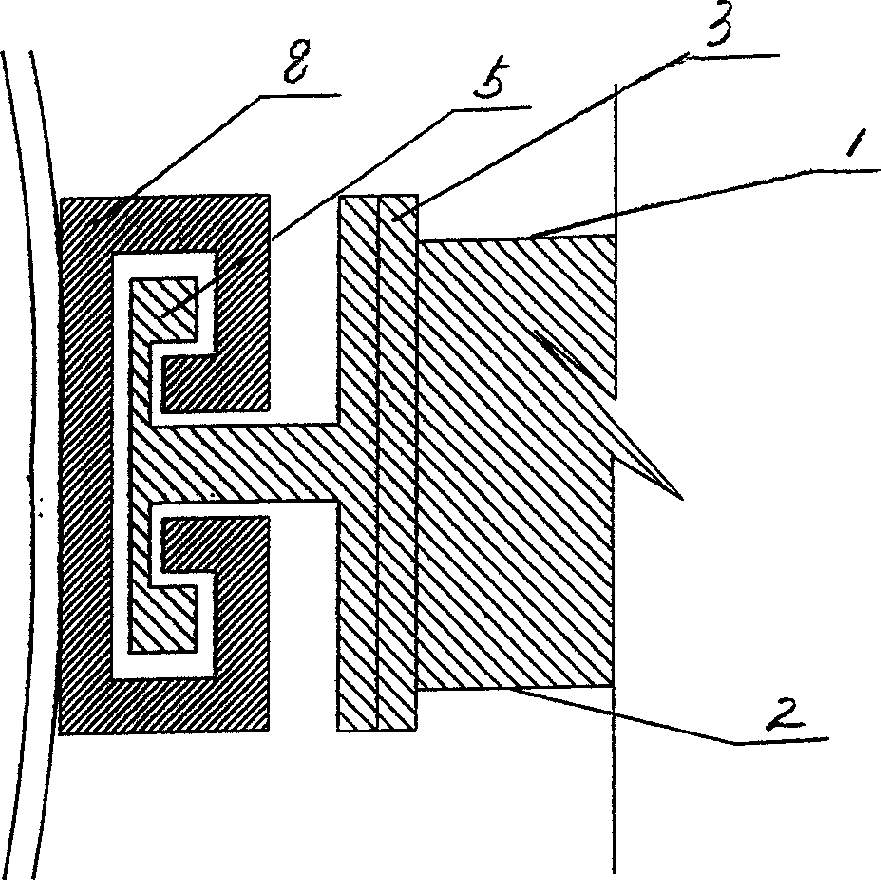

[0019] The present invention will be further described below with reference to the accompanying drawings: the construction method of the present invention is essentially to connect the cast-in-situ concrete tubular piles and the sheet piles with special equipment consisting of a tube pile hole former with a guiding structure and a sheet pile pile former. To form a conjoined body, the method is:

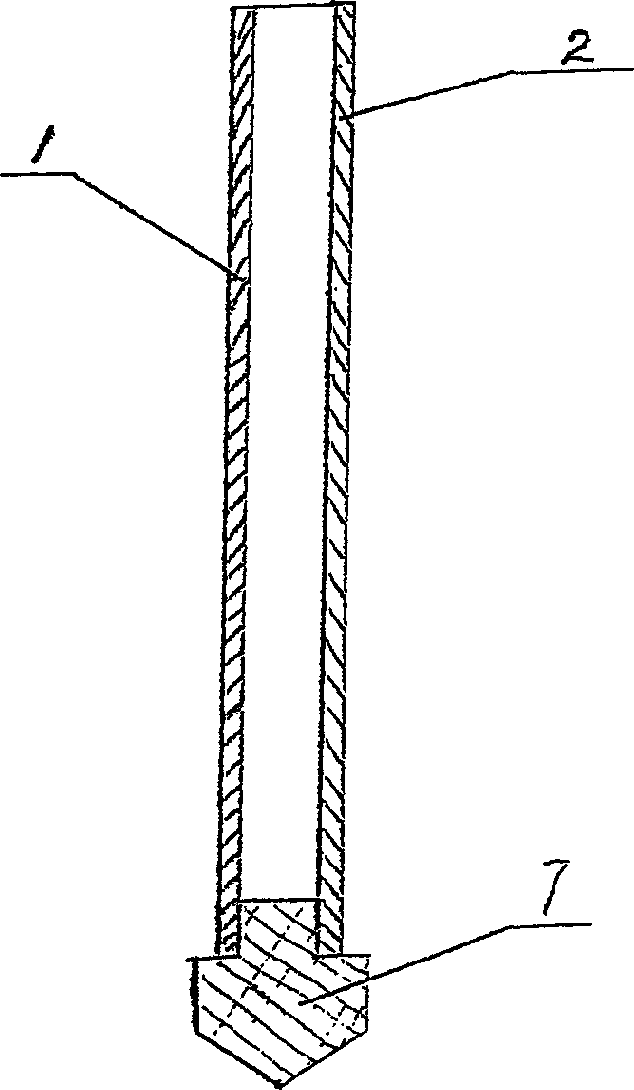

[0020] (1) Pile shoes are installed at the bottom of the tube pile hole former and the sheet pile pile former in the special equipment used;

[0021] (2) Put the tube pile hole maker upright in the construction position and apply pressure on the vibrating head to make the tube pile hole maker sink to the designed depth of soil;

[0022] (3) The sheet pile forming device is erected in the construction position, the insert 5 on the first wing plate 1 and the receiving insert 8 of the tube pile hole forming device are connected and positioned and matched, and the sheet pile forming device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com