Area light source device and light board thereof

A light guide plate and surface light source technology, applied in optics, nonlinear optics, diffuser elements, etc., can solve problems such as uneven distribution of light energy and uneven energy distribution of light sources, and achieve good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

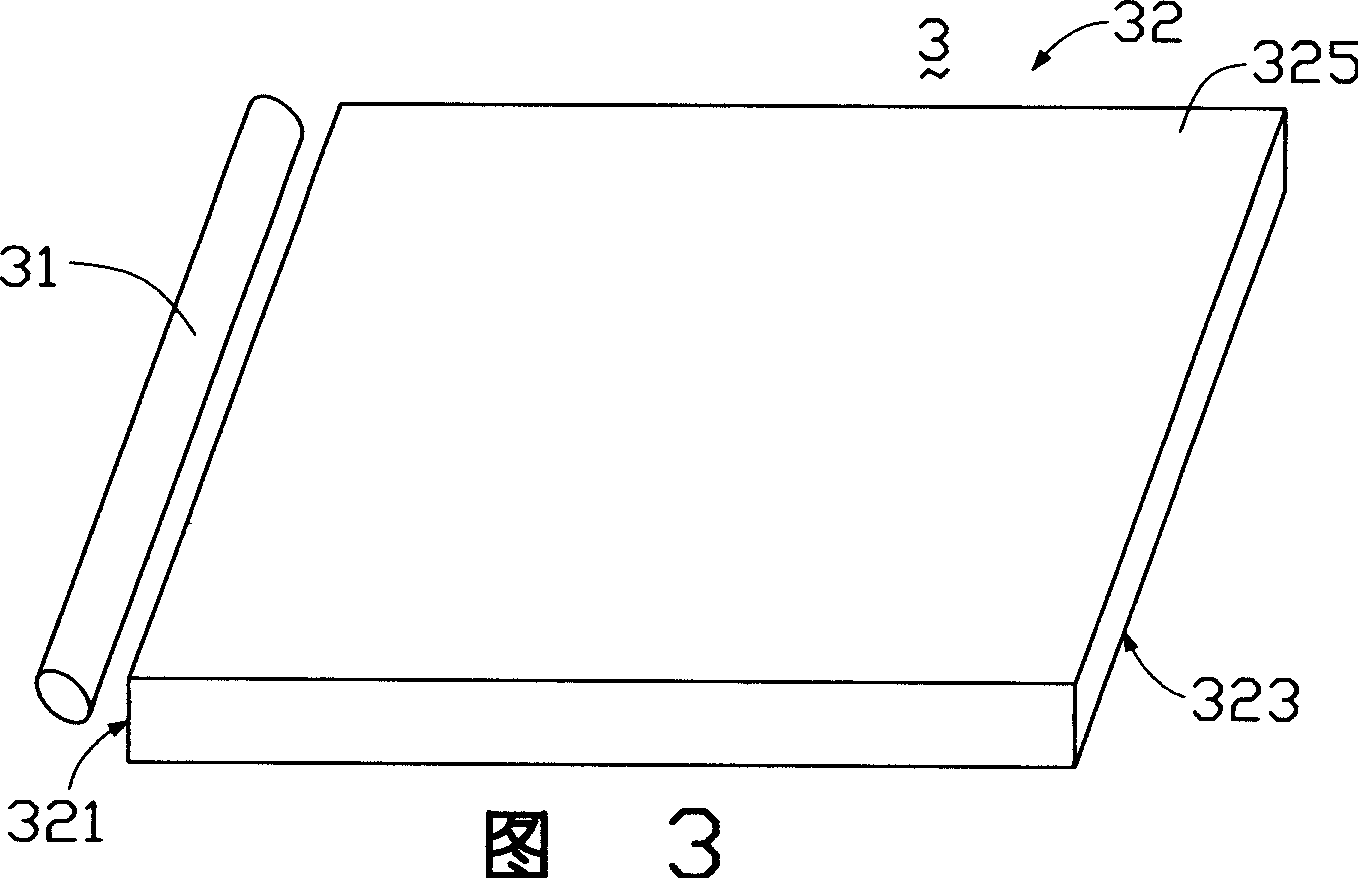

[0017] Please refer to Figure 3 and Figure 4 The surface light source device 3 according to the first embodiment of the present invention includes a light guide plate 32 and a light source 31 disposed on one side of the light guide plate 32 . The light guide plate 32 includes a light incident surface 321 for receiving light, a light exit surface 325 guiding light to exit and intersecting the light incident surface 321 , and a bottom surface 323 opposite to the light exit surface 325 . The light source 31 is a linear light source disposed on the light incident surface 321 side of the light guide plate 32 , such as a cold cathode fluorescent lamp. Because the luminance distribution of the light source 31 itself is uneven, the luminance distribution in the middle part is stronger and uniform, and the luminance distribution at the two ends is weaker and the luminance gradually increases from the two ends to the middle part, so the light incident on the light guide plate adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com