Vertical pipe vacuum pre pressing bidirectional slip casting method and sealed slip casting system thereof

A grouting system and grouting technology, applied in mining equipment, earthwork drilling, bolt installation, etc., can solve problems such as stress loss, anchor cable body corrosion, channel grouting is not dense, failure, etc., to achieve enhanced integrity, Promotes the effect of increasing the vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

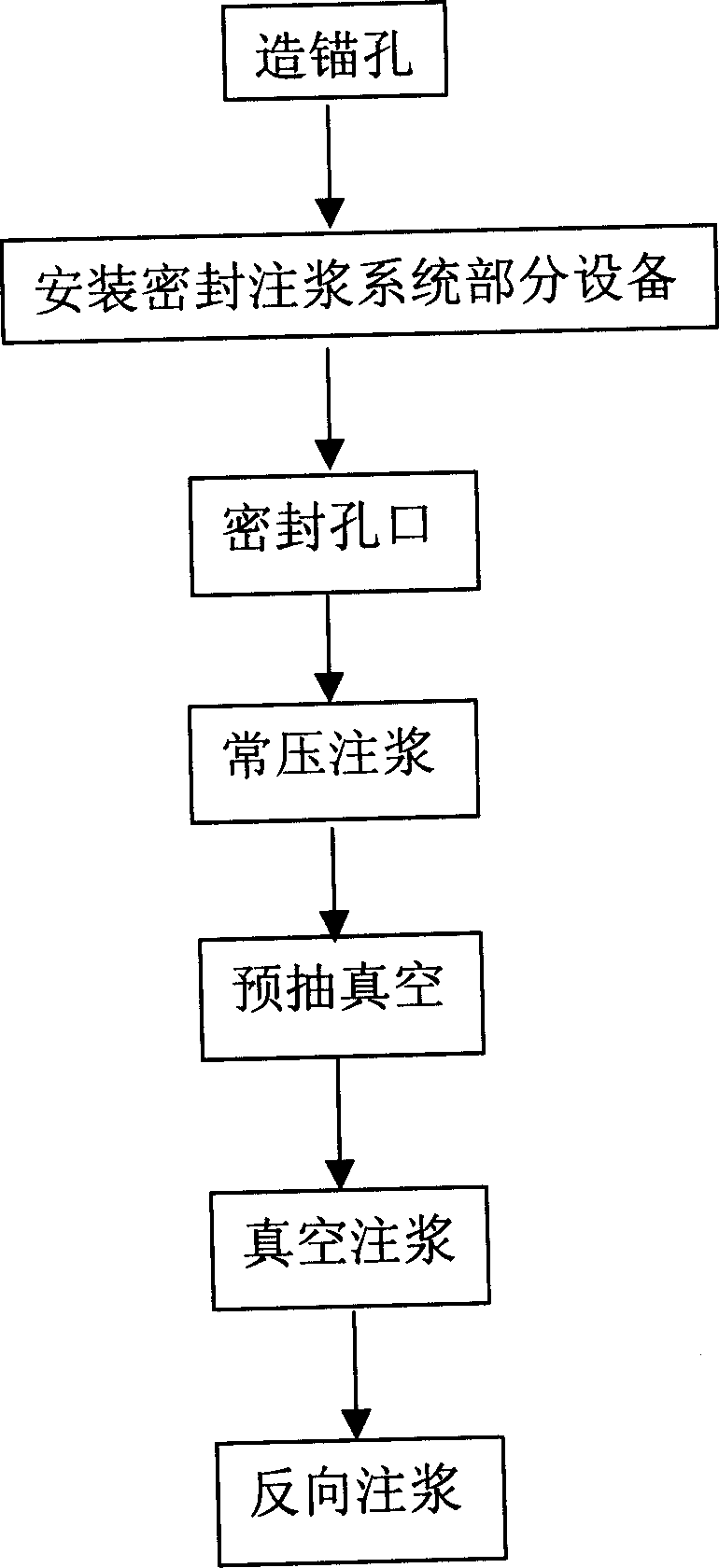

[0034] A vertical tube vacuum preloading two-way grouting method includes the following main steps:

[0035] A. Making anchor holes: drill vertical or diagonally upward anchor holes in the surrounding rock;

[0036] B. Install some equipment of the sealed grouting system:

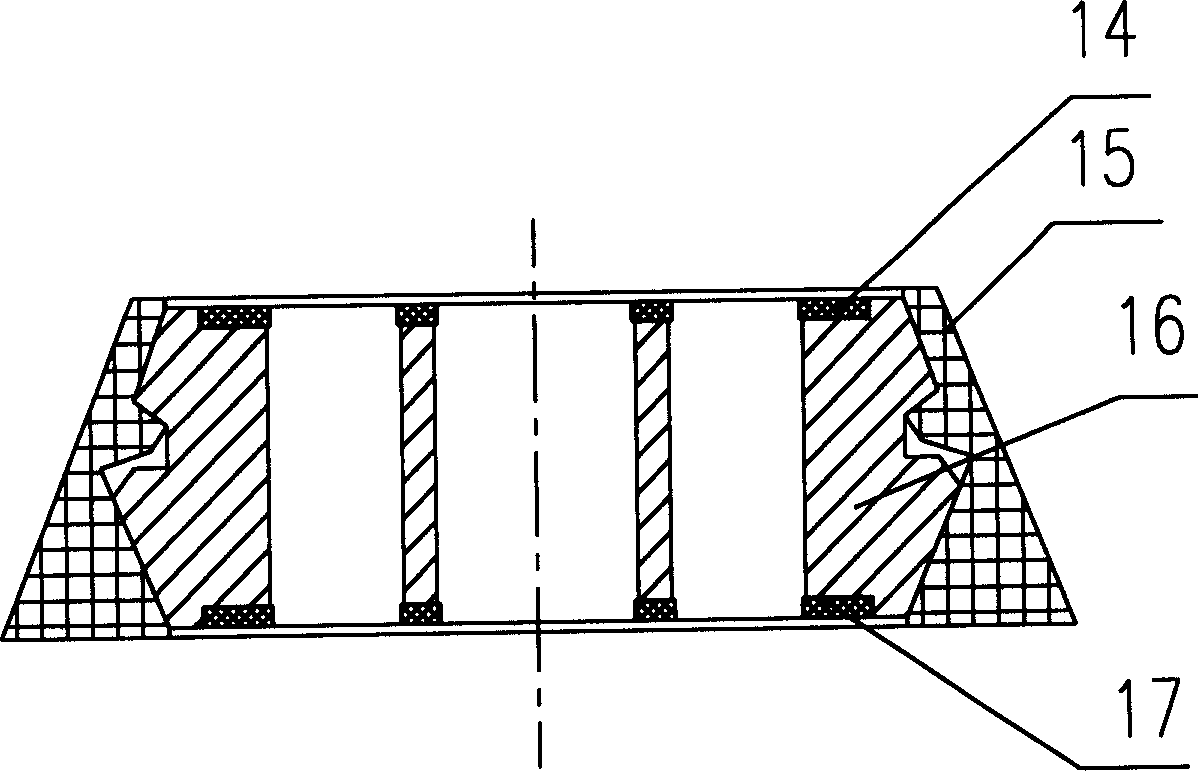

[0037] B1: Install the anchor cable: press figure 2 Install the anchor cable, all accessories, and vacuum tube, and tie them firmly, and feed the anchor cable straight into the anchor hole;

[0038] B2: Install the orifice stopper, install the bowl-type grout stopper with grouting pipe;

[0039] B3: Install vacuum pump, negative pressure vessel, grouting pump;

[0040] C. Sealing the orifice: Use epoxy resin to bond the stopper, the junction between the end face of the orifice and the hole wall and the anchor cable prestressed tendons, and install the sealing plate to seal the orifice;

[0041] D. Normal pressure grouting: Under normal pressure, a section of quick-setting slurry is pre-injected through the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com