Method for preparing isobutylene block copolymer by sequential initiation

A technology of block copolymer and isobutylene, applied in the field of preparation of block copolymer, can solve the problems of increased cost, complicated process, inability to realize active polymerization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

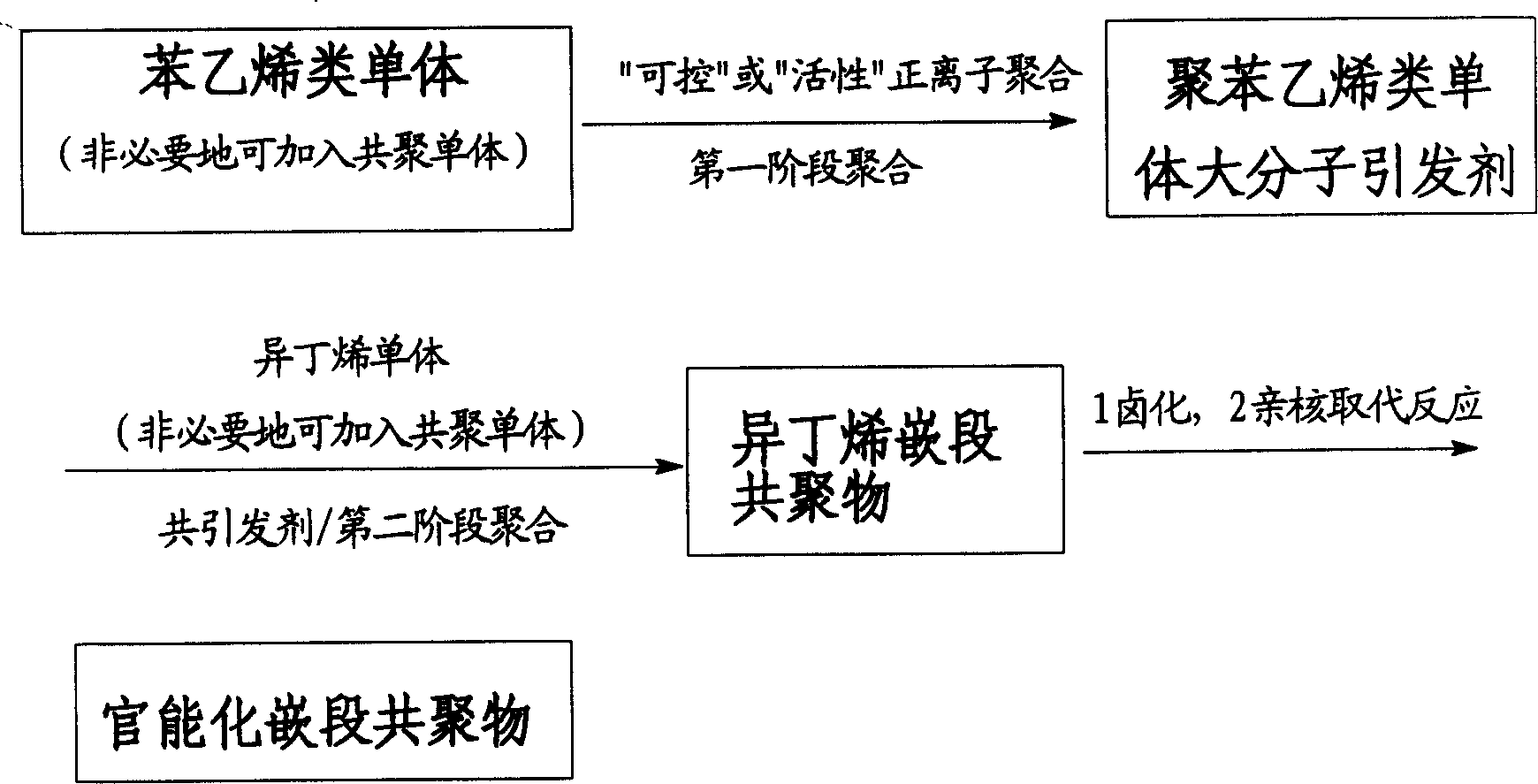

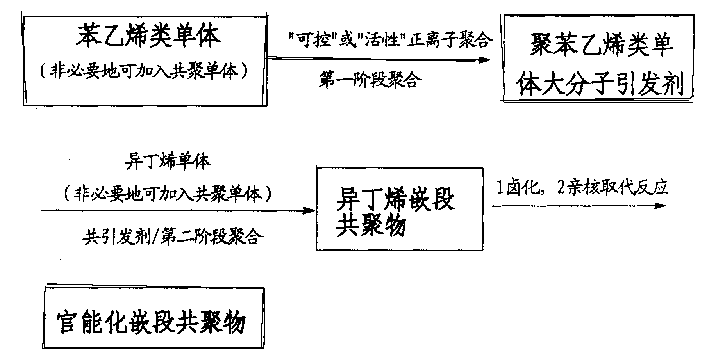

Method used

Image

Examples

Embodiment 1

[0036] Add 30ml of methyl chloride to a dry nitrogen-filled reactor, and then add about 60mg of n-Bu 4 N + Cl - , 2.06 g p-methylstyrene, 18 μl 1-phenylethyl chloride, the reaction mixture was cooled to -40 °C, and then 50 μl SnCl was added 4 Start the first phase of aggregation. After 1 hour of polymerization reaction, a small amount of sample was taken to determine the relative molecular mass of poly-p-methylstyrene. Then add 2.04g of isobutene, cool to -80°C, add 0.2ml of AlEt 2 Cl (10M hexane solution) for the second stage of polymerization. After 30 minutes of polymerization, 2 ml of methanol was added to terminate the polymerization, the polymer was precipitated with methanol, and about 4.0 g of the polymer was obtained after drying. The number average relative molecular mass measured by GPC was 19200 (MWD=1.46) for poly-p-methylstyrene, and 36600 (MWD=1.42) for poly-p-methylstyrene-b-polyisobutylene.

Embodiment 2

[0038] Add 20ml of methyl chloride to a dry nitrogen-filled reactor, then add about 25mg of n-Bu 4 N + Cl - , 1.5 g p-methylstyrene, 15 μl 1-phenylethyl chloride, the reaction mixture was cooled to -40 °C, and then 50 μl SnCl was added 4 The first stage of polymerization was started and the polymerization was carried out for 1 hour. Then add 1.8g of isobutene and 18 mg of divinylbenzene, cool to -80°C, add 0.1ml of AlEt 2 Cl (10M hexane solution) for the second stage of polymerization. After 30 minutes of polymerization, 2 ml of methanol was added to terminate the polymerization, the polymer was precipitated with methanol, and about 3.2 g of the polymer was obtained after drying. There are about 10% cyclohexane insoluble matter in the polymer product, and the number-average relative molecular mass of the soluble part measured by GPC is 25300 (MWD=4.13), and the GPC spectrum shows double peaks. This indicates that the poly(isobutylene-co-divinylbenzene) part has undergone ...

Embodiment 3

[0040] Add 30ml of dichloromethane into a dry nitrogen-filled reactor, and then add about 25mg of n-Bu 4 N + Cl - , 1.8 g styrene, 15 μl 1-phenylethyl chloride, the reaction mixture was cooled to -40 °C, and then 200 μl SnCl was added 4 The first stage of polymerization was started and the polymerization was carried out for 4 hours. Then add 1.8g of isobutylene and 100 mg of p-methylstyrene, cool to -80°C, add 0.1ml of AlEt 2 Cl (10M hexane solution) for the second stage of polymerization. After 30 minutes of polymerization, 2 ml of methanol was added to terminate the polymerization, the polymer was precipitated with methanol, and about 3.67 g of polymer was obtained after drying. The number average relative molecular mass measured by GPC is 35300 (MWD=1.65), 1 The p-methylstyrene content of the polyisobutylene block determined by H-NMR was about 5.2% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com