Exhaust structure of accumulator

A battery and exhaust chamber technology, applied in the direction of structural parts, electrical components, battery pack components, etc., can solve the problems of liquid leakage, leakage of liquid exhaust nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

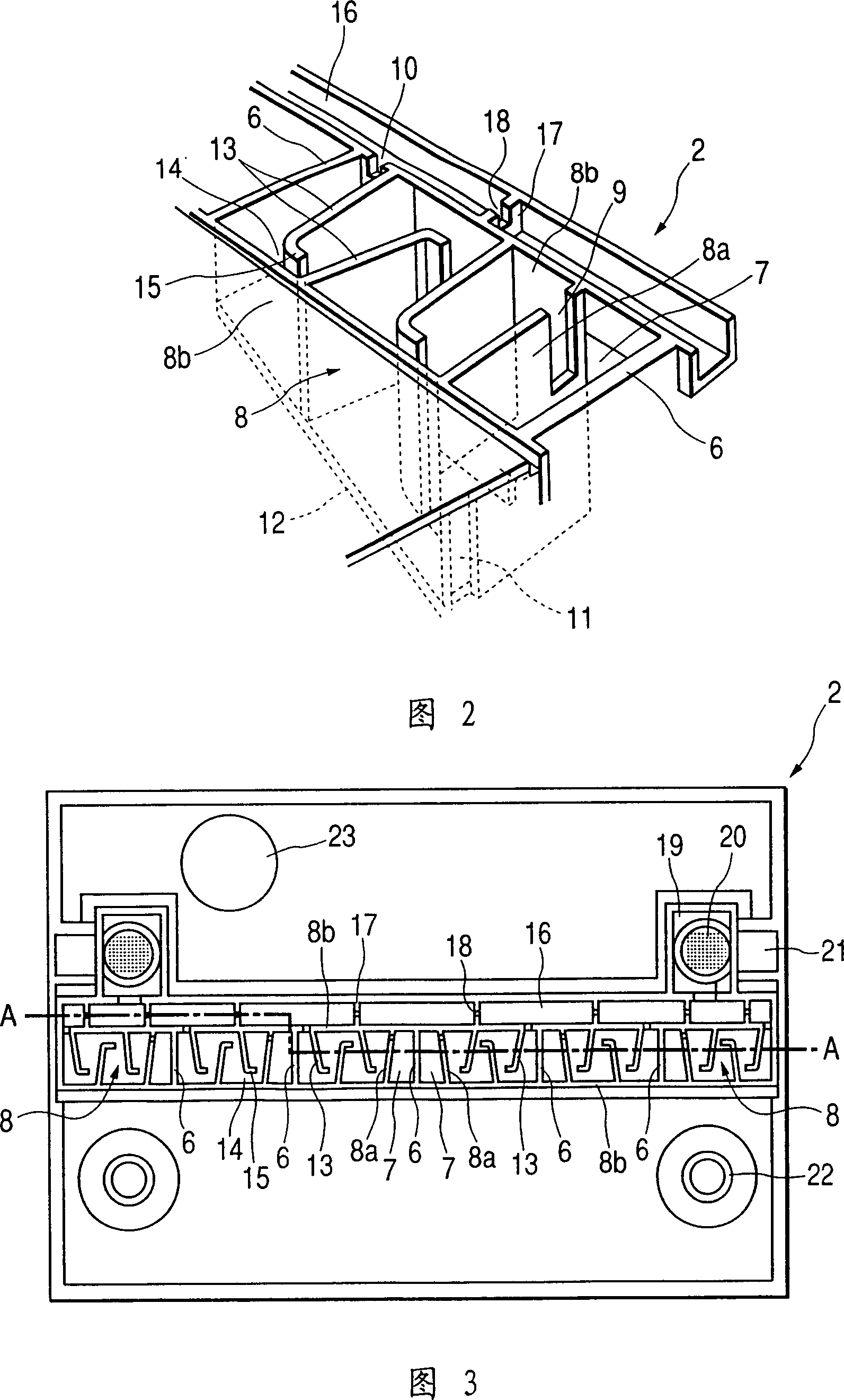

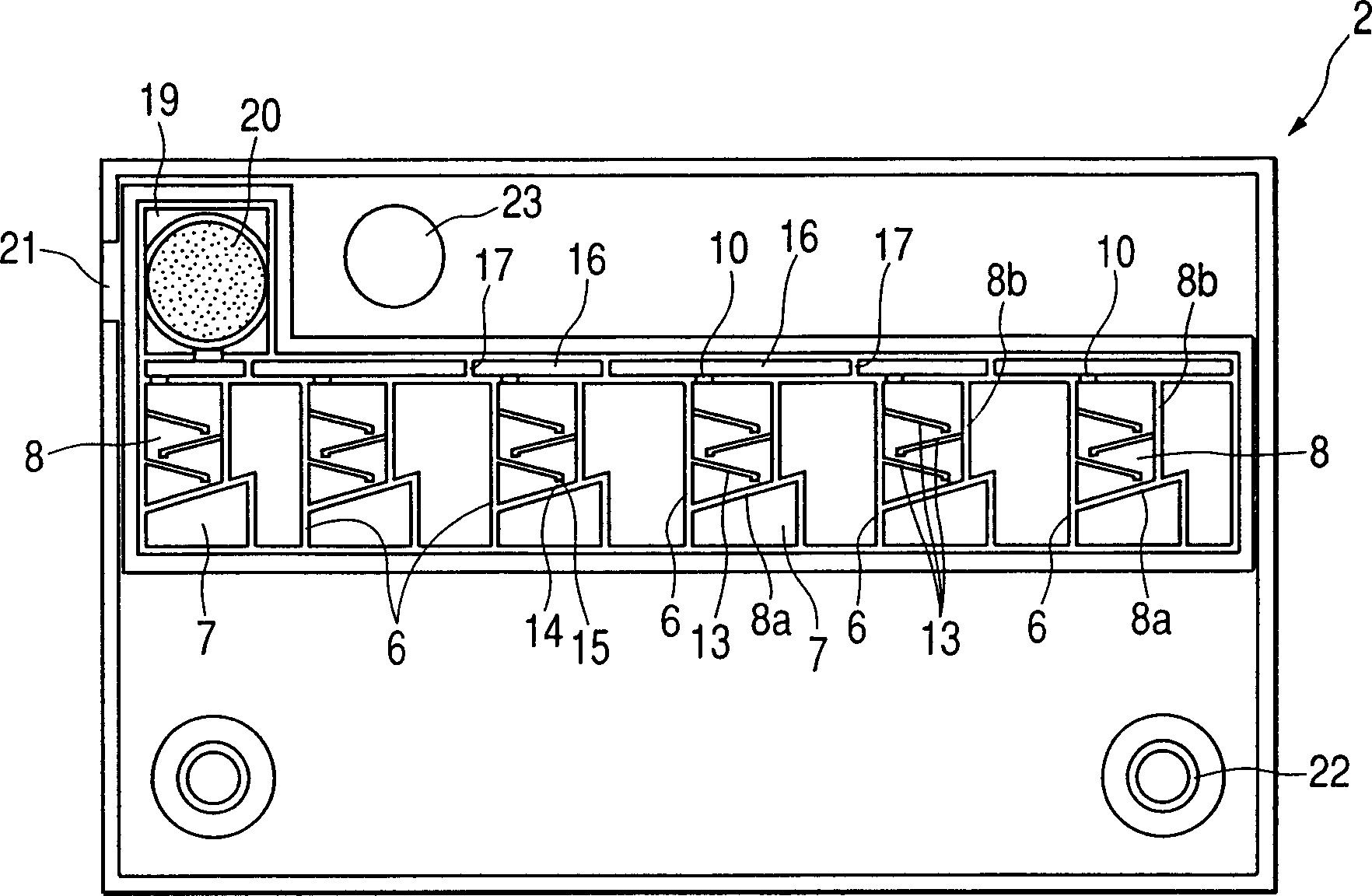

[0020] Preferred embodiments of the present invention will be described with reference to the accompanying drawings.

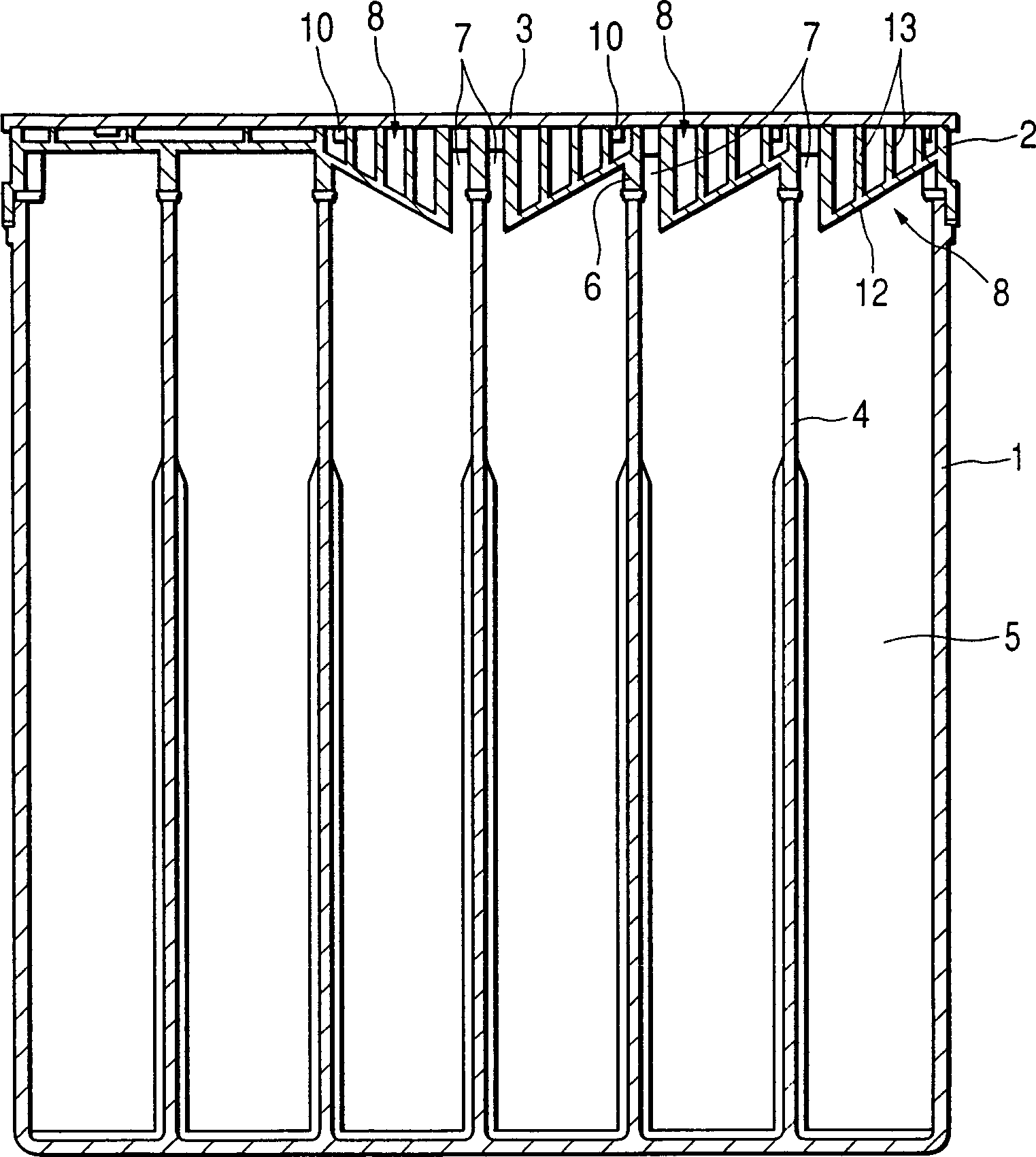

[0021] like figure 1 As shown, in the storage battery according to the first embodiment of the present invention, the interior of the battery case 1 is divided into six battery chambers 5 by the partition wall 4 . In each battery chamber 5 is accommodated an electrode plate member (not shown in the figure) in which positive and negative plates are alternately laminated and has a separator therein. The electrode plate elements in each battery chamber are connected in series through the partition wall 4 .

[0022] The casing 2 is welded to the battery box 1 to close the upper opening of the battery box 1 . On the opposite side of the casing 2, partition walls 6 are formed corresponding to the partition walls 4 in the battery case 1 respectively, and these partition walls 6 are welded to the partition walls 4 of the battery case 1 respectively, so that the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com