Multifunctional device for manufacturing marking labels

A mass-produced, multi-functional technology, applied in the identification device, conductive connection, printing and other directions, can solve the problems of production process consumption, difficult separation of nameplates, punching, marking, etc., to reduce processing consumption and simplify the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

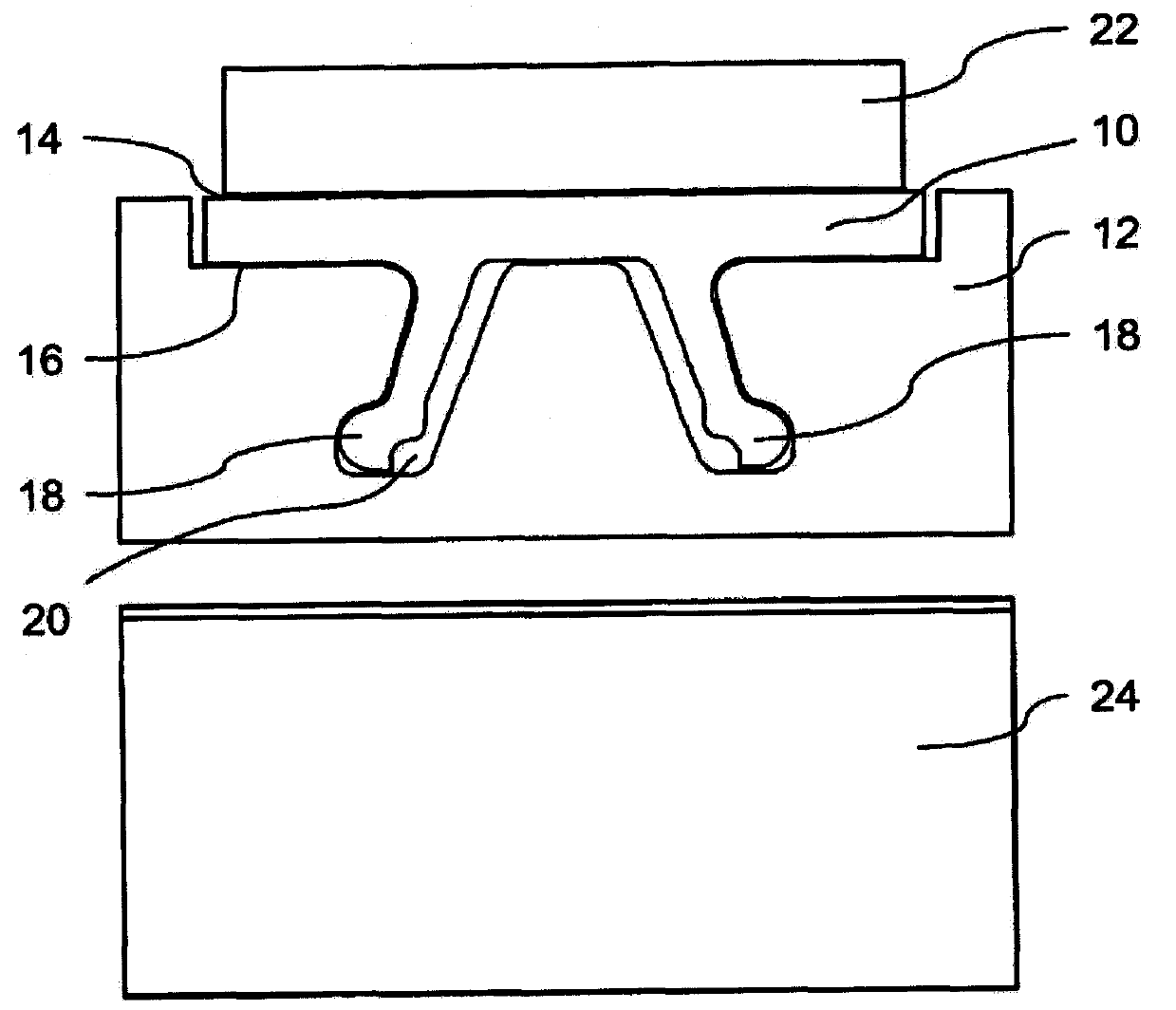

[0030] figure 1 shows a multifunctional device for the mass production of nameplates 10, in particular nameplates for junction boxes. The multifunctional device has a stamping device for writing a nameplate (no specific structure is shown here), and a separation device for separating the nameplate with a required length, and / or a device for separating the nameplate with a required length. A punching device for punching nameplates. Preferably, the unwritten nameplate 10 is rolled into a roll from an end or endless stock and is then transported via a conveying unit (not shown here) to the multifunctional device, in particular to an embossing device of the multifunctional device. Inside the multifunctional device, the roll of nameplate 10 is unrolled and then secured in the receiving part 12 before being conveyed to the embossing device and the separating and / or punching device.

[0031] The nameplate 10 has a top side 14 to be embossed and a bottom side 16 opposite the top sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com