Locking means

A locking device and keyhole technology, applied in the application of building locks, vehicle locks, locks, etc., to prevent wrong assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

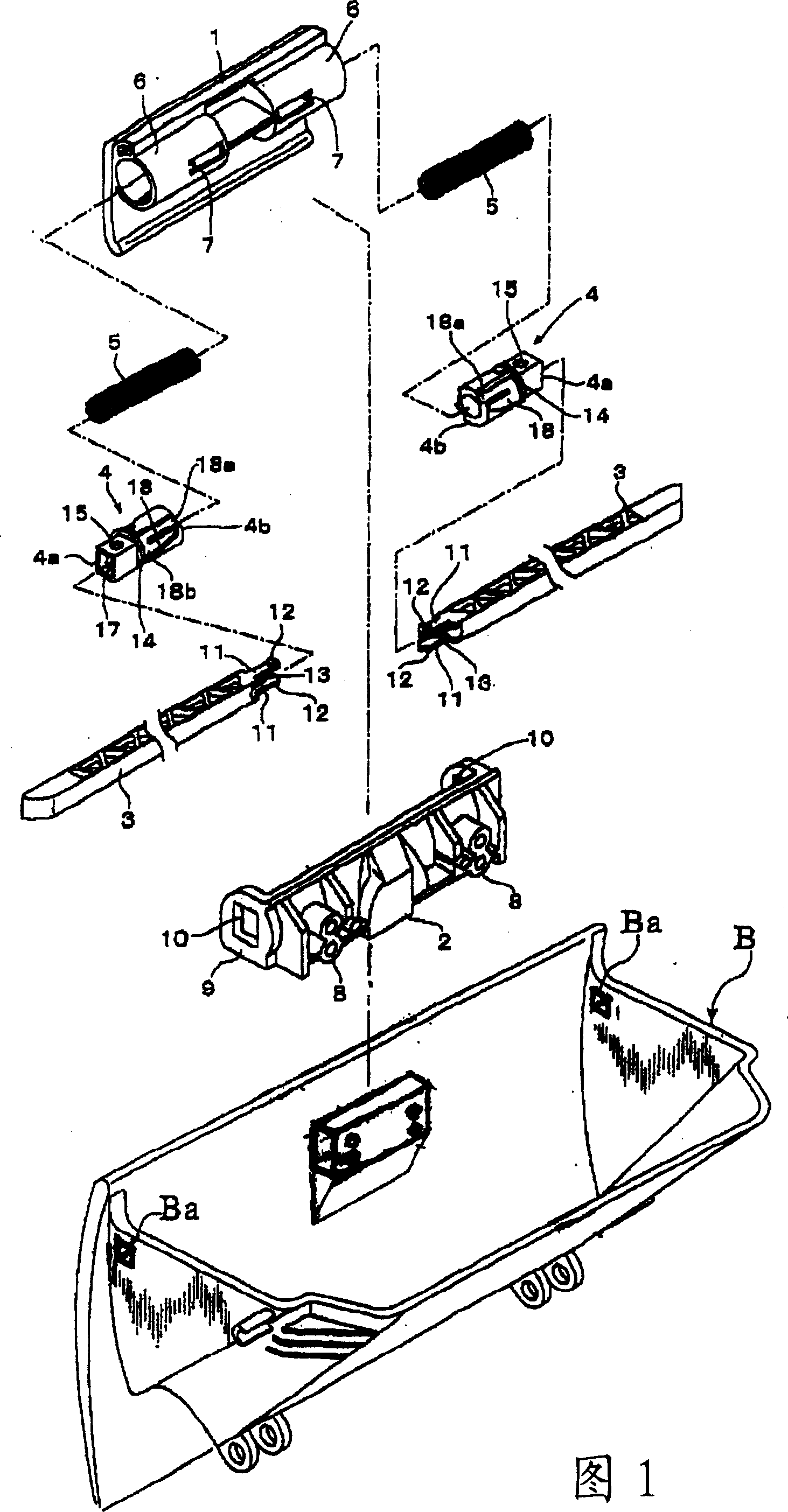

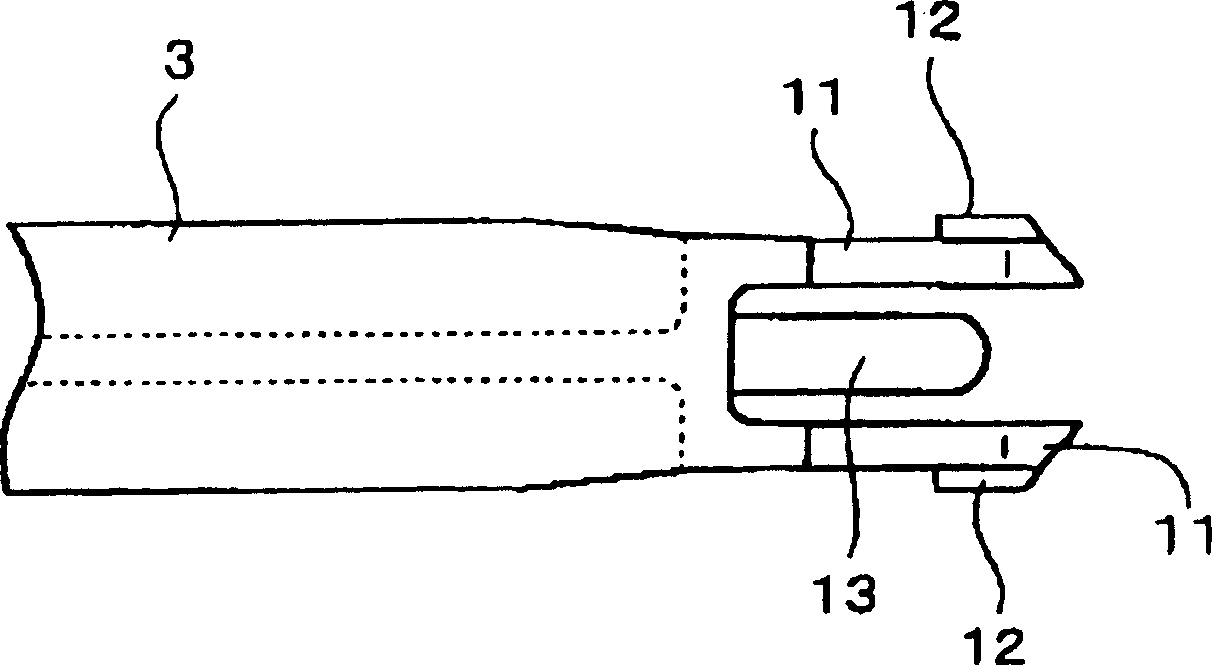

[0048] Also, as shown in FIG. 1, the locking device according to the first embodiment includes: an operating handle 1; a support frame 2; a pair of left and right sliding pins 3; a pair of left and right cam parts 4; spring 5. The operating handle 1 is supported to be swingable within a concave portion defined in the front wall of the glove box main body. The support frame 2 fixes the operating handle 1 to the connecting wall extending to the inner side of the concave part through screw connection. The cam members 4 push the slide pins 3 to extend and retract them, respectively. Compression coil springs 5 respectively push said slide pins 3 toward the lock holes defined in the instrument panel.

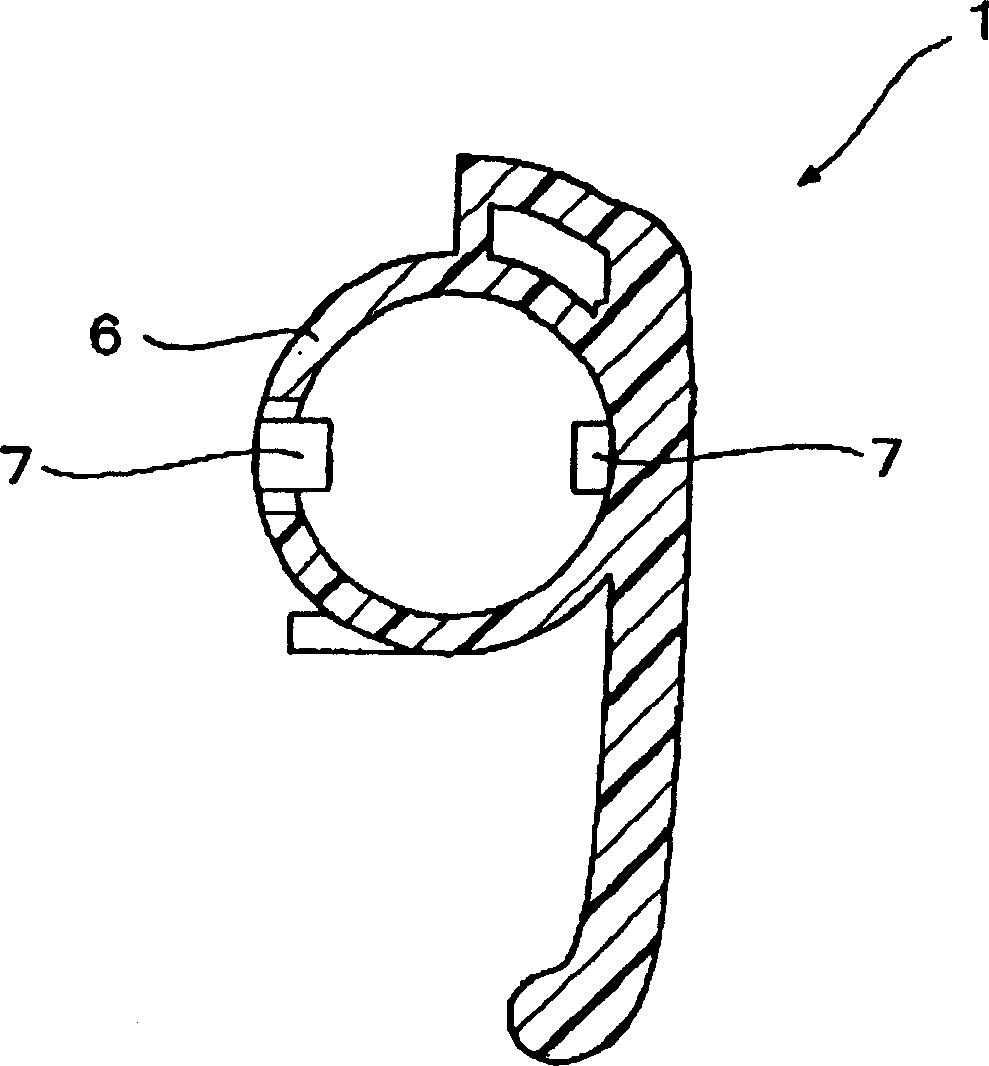

[0049] as well figure 2 As shown, on the back side of the operating handle, a pair of left and right cylindrical portions 6 each for accommodating the slide pin 3 and the compression coil spring 5 are integrally formed. On inner surfaces disposed opposite to each other in each c...

no. 2 example

[0061] As shown in Figure 11, the locking device according to the second embodiment includes: an operating handle 101, a support frame 102, a pair of left and right sliding pins 103, a pair of left and right cam parts 104, two compression coil springs 105 and O Ring 124. The operating handle 101 is disposed inside the concave portion defined in the front wall of the glove box body to open and close the glove box main body. The supporting frame 102 is threadedly coupled to the connecting wall extending to the inner side of the concave portion and supports the operating handle 101 so that it can swing. The cam members 104 push the corresponding slide pins 103 to extend and retract, respectively. The compression coil springs 105 respectively push the slide pins 103 toward the direction of the lock holes defined in the instrument panel. An O-ring 124 is connected to the cam member to provide braking force as will be described below.

[0062] Such as Figure 12 As shown, on the...

no. 3 example

[0085] Next, a locking device according to a third embodiment will be described. The locking device according to the third embodiment differs from that of the second embodiment in that it acts as a central locking device for a glove box. The basic structure of the locking device according to the third embodiment is similar to that of the second embodiment. That is, if Figure 18 As shown, the locking device includes an operating handle 101 , a support frame 102 , a sliding pin 103 , a cam member 104 , a compression coil spring 105 and an O-ring 124 .

[0086] However, since the third embodiment described has an operating handle 101 with a vertical swing axis as a central locking device, a separate cylindrical portion 106 is formed on the rear side of the handle. A single cam member 104 having an accommodation groove 125 fitted with an O-ring 124 and a single compression coil spring 105 are inserted into the single cylindrical portion 106 in up and down directions. A curved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com