Suface acoustic wave filter

A filter and resonator technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of low productivity, small degrees of freedom of ladder filters, etc., and achieve the effect of small insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

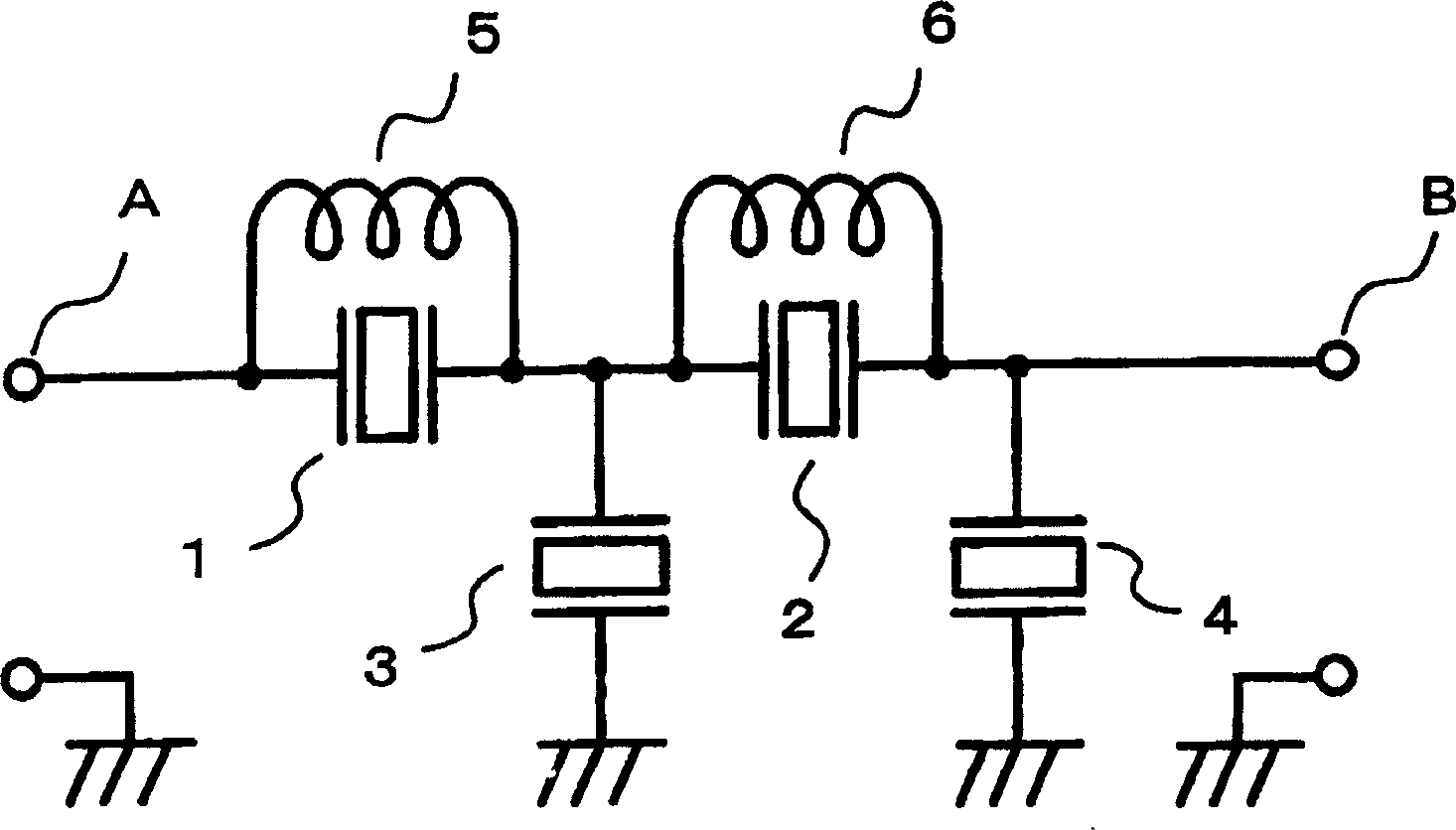

[0022] like figure 1 As shown, a SAW filter according to an embodiment of the present invention includes a two-stage ladder filter having four SAW resonators 1 to 4 . This SAW filter has an input terminal A located at the left end as shown in the figure, and an output terminal B located at the left end as shown in the figure. The SAW resonators 1, 2 on series arms are inserted in series between the input and output terminals A, B. The SAW resonator 3 on the parallel arm is inserted between the connection point between the SAW resonators 1, 2 and the ground point. The SAW resonator 4 on the parallel arm is inserted between the connection point between the SAW resonator 2 and the output terminal B and the ground point. The SAW filter also has inductors 5, 6 connected in parallel with the SAW resonators 1, 2 on the series arms, respectively.

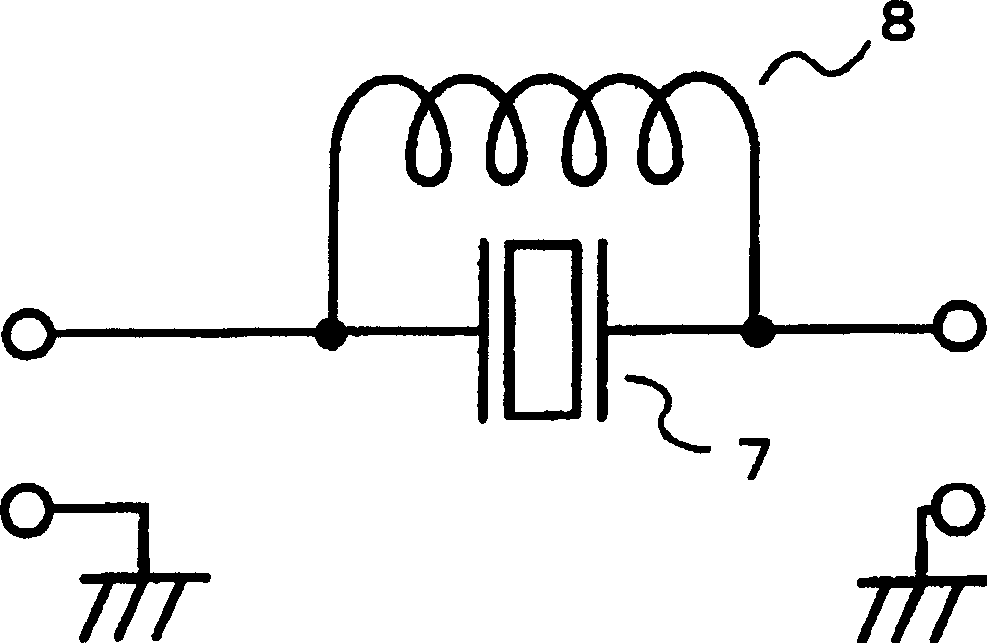

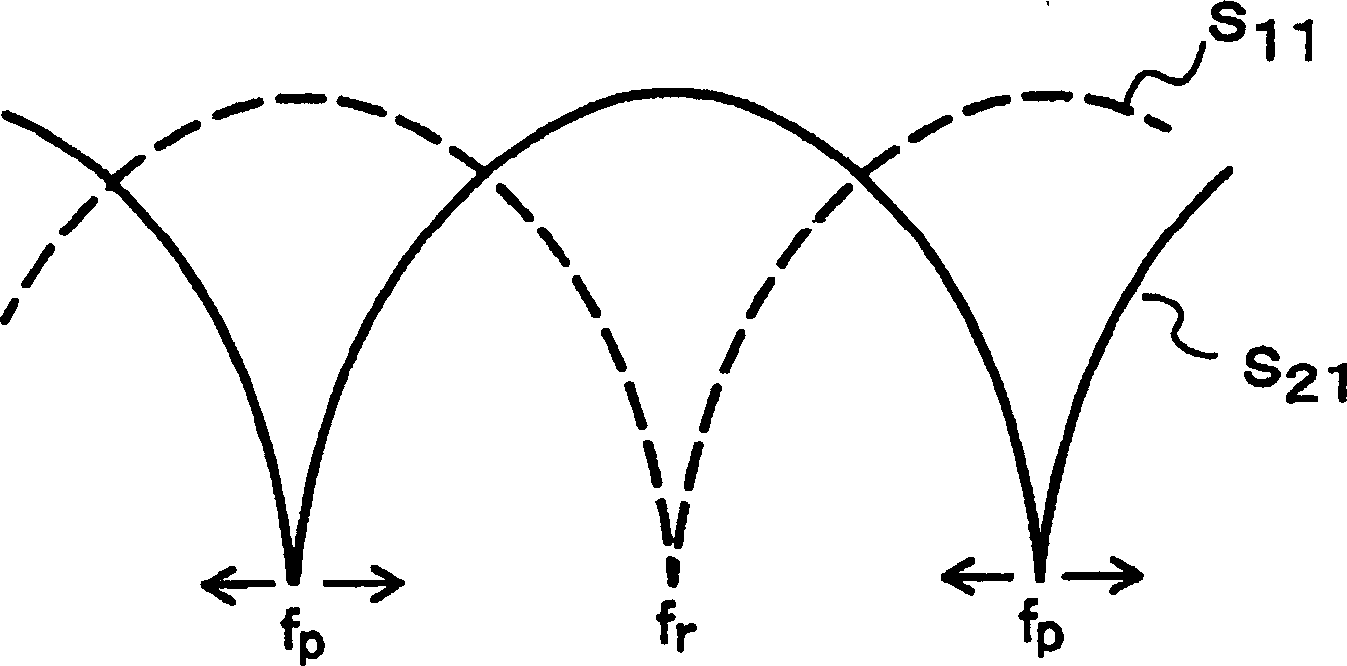

[0023] The characteristics of an assembly including a SAW resonator on a series arm, and an inductor connected in parallel to the SAW r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com