Flexible flat cable connecting method and boom structure of ultrasonic bonding machine

A flexible flat cable, ultrasonic welding technology, applied in the direction of connection, welding equipment, non-electric welding equipment, etc., can solve the problems of reducing the vibration energy of the conductive element 4 and the inability to achieve ultrasonic welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

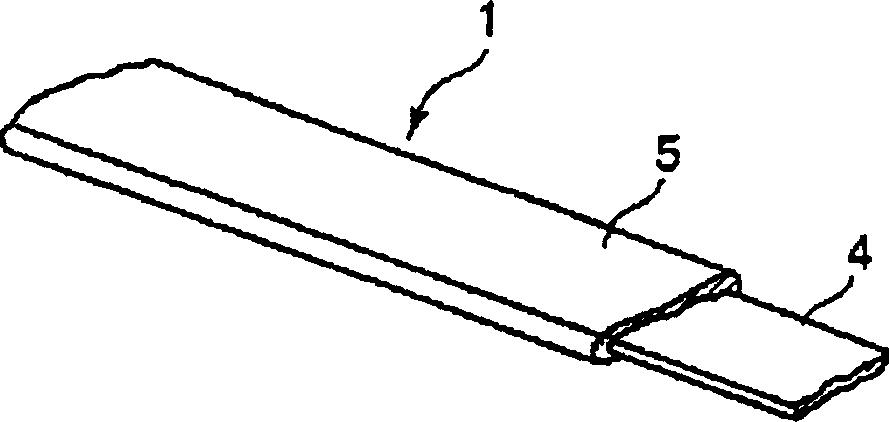

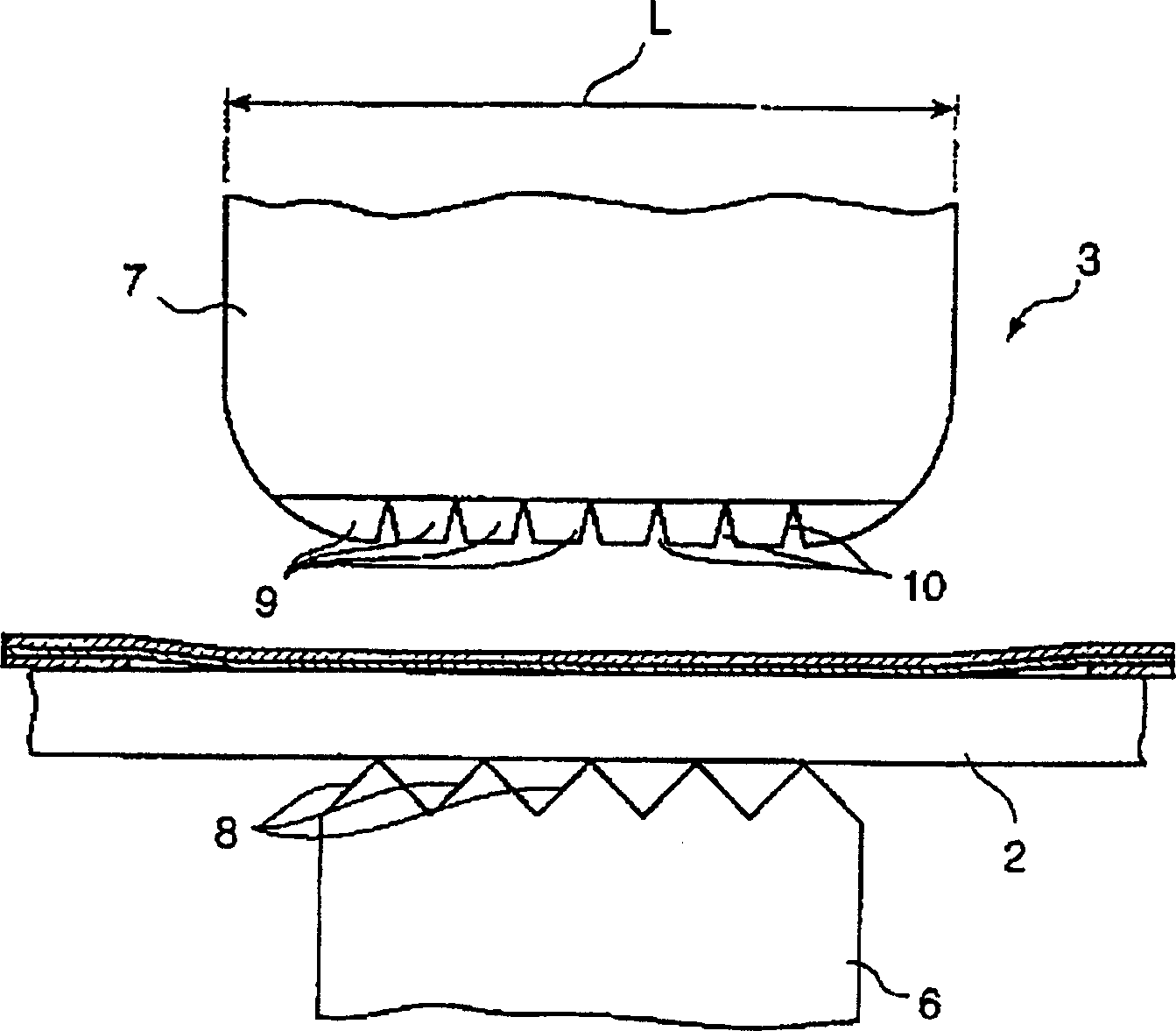

[0053] figure 1 A specific structure of the flexible flat cable 1 is shown, while Figure 2 to Figure 4 The basic structure of an ultrasonic welder 3 for connecting a flexible flat cable to an element to be connected, such as a busbar 2, is shown. Flexible flat cable 1, such as figure 1 As shown, a conductive element 4 made of copper foil having a thickness of 35 μm is covered by an insulating cover layer 5 made of, for example, PET (polyethylene terephthalate).

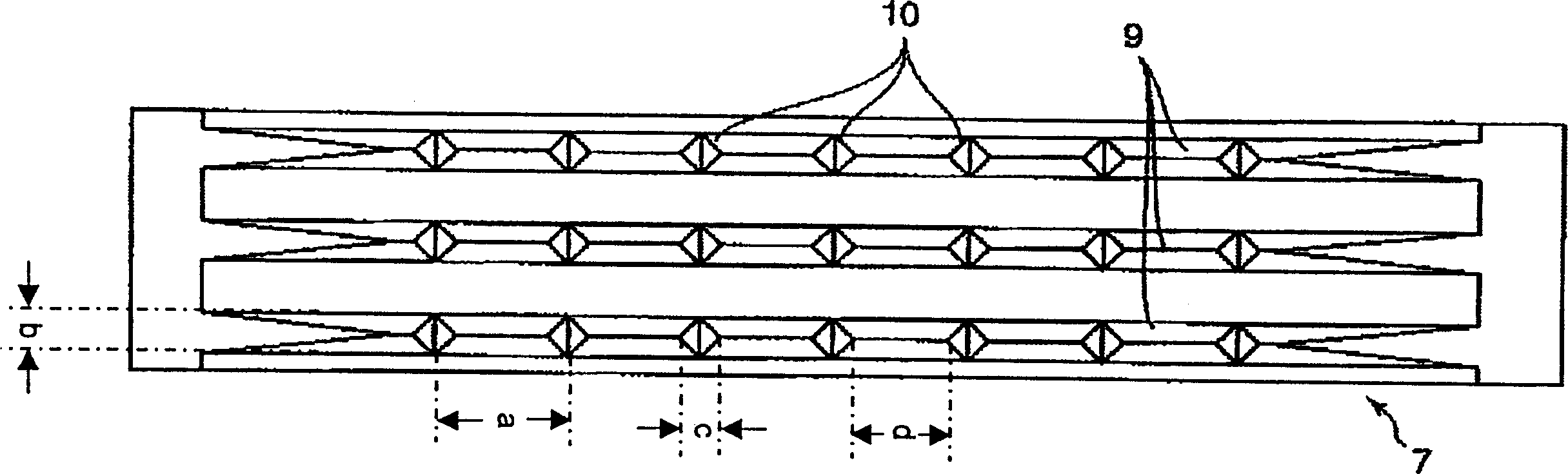

[0054] Such as figure 2 As shown, the ultrasonic welding machine 3 has an anvil 6 on which elements to be welded such as busbars 2 are placed, and an arm 7 for compressing the conductive element 4 of the flexible flat cable 1 and Busbar 2 is in contact. Tapering or converging protrusions 8 having a (preferably approximately right-angled) isosceles triangular cross-section are formed on the upper surface of the anvil 6 (the surface facing the bus bar 2 and / or the flexible flat cable 1), while the bus bar 2 On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com