Full optical fiber current measuring method

A current test, all-fiber technology, applied in the field of all-fiber current test, can solve the problems of large influence of temperature, instability of optical polarization state, etc., to eliminate the influence of the system, ensure the test accuracy, and enhance the effect of commercial development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

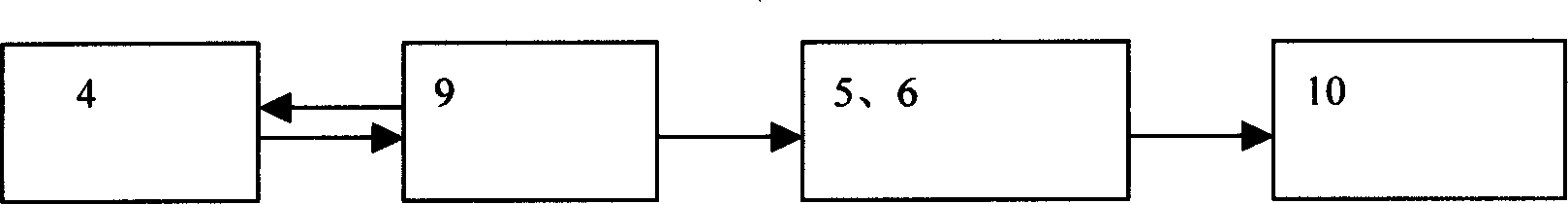

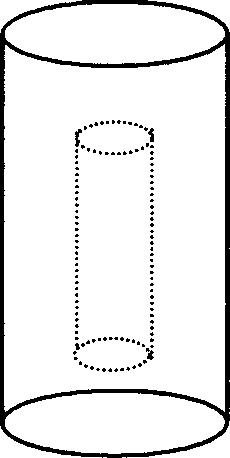

[0045] To verify the proposed current test method, experimental tests were carried out with an AC current with a maximum peak value of 6.6 amperes and a frequency of 50 Hz. The specific experimental structure diagram is as follows: figure 1 As shown, the light emitted by the laser (1) enters the fiber coupler (2) through a jumper connection, and after being split, one path of light passes through the fiber delay line (3) from the coupler (7) to the sensor probe (4 ), and finally return to the end of the optical fiber (8); another beam of light is from the end of the coupler (8), passes through the sensing head (4), reaches the fiber delay line (3), returns to the end of the fiber coupler (7), and interferes After the signal is received by the photoelectric detector (5) (6), an electrical signal is obtained. The electrical signal is amplified by an amplifier circuit, collected by a data acquisition card, and subjected to data processing to obtain a current signal.

[0046] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com