Two-cutter parallel-cutting harvester of cutting and pulverizing for stem or straw green fodder

A technology for silage and harvester, which is applied to cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of unsuitable harvesting, crushing processing, high manufacturing and use costs, and high planting density, and achieves simple structure and low cost. Inexpensive, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and preferred embodiment the present invention is described in further detail:

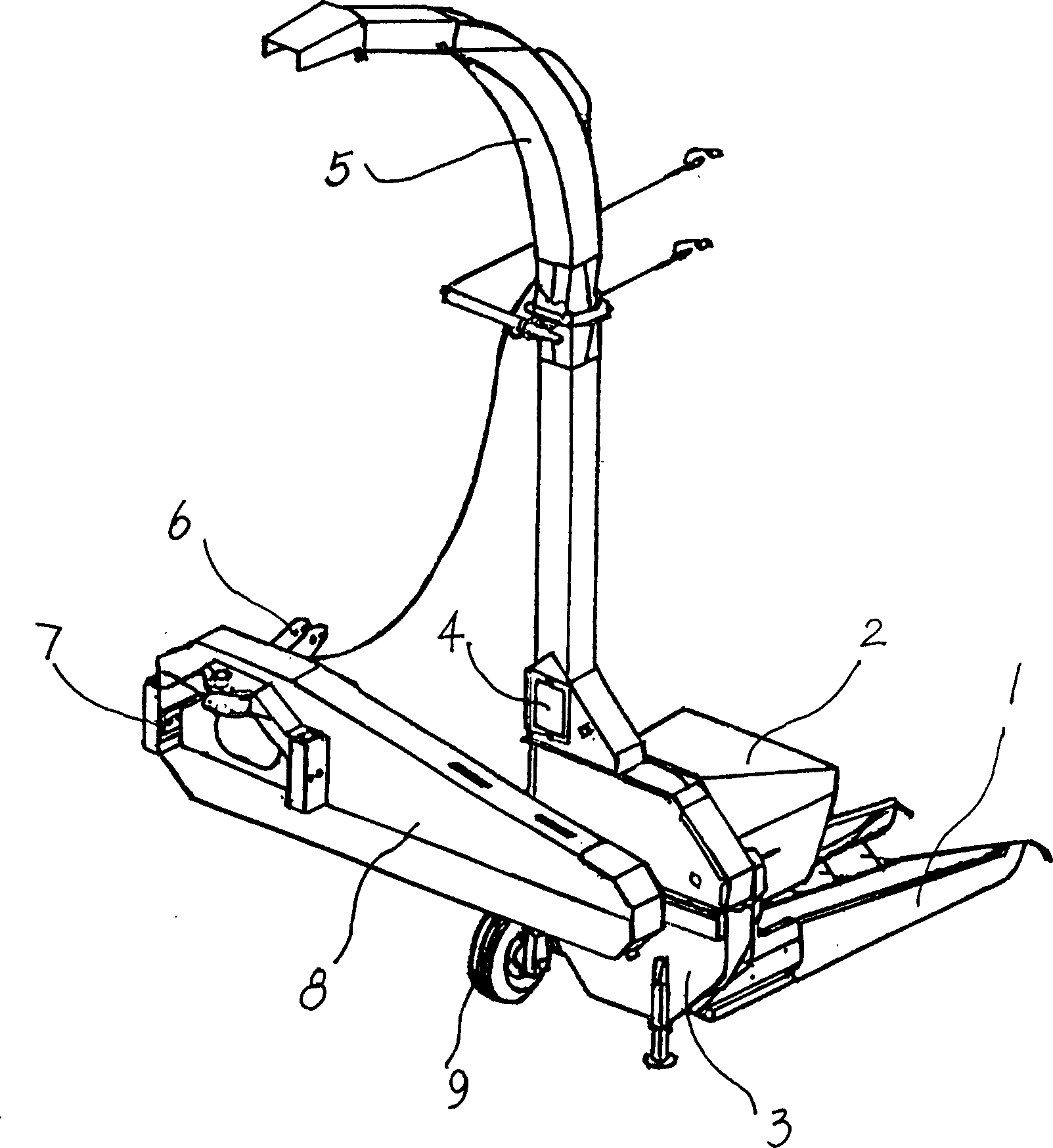

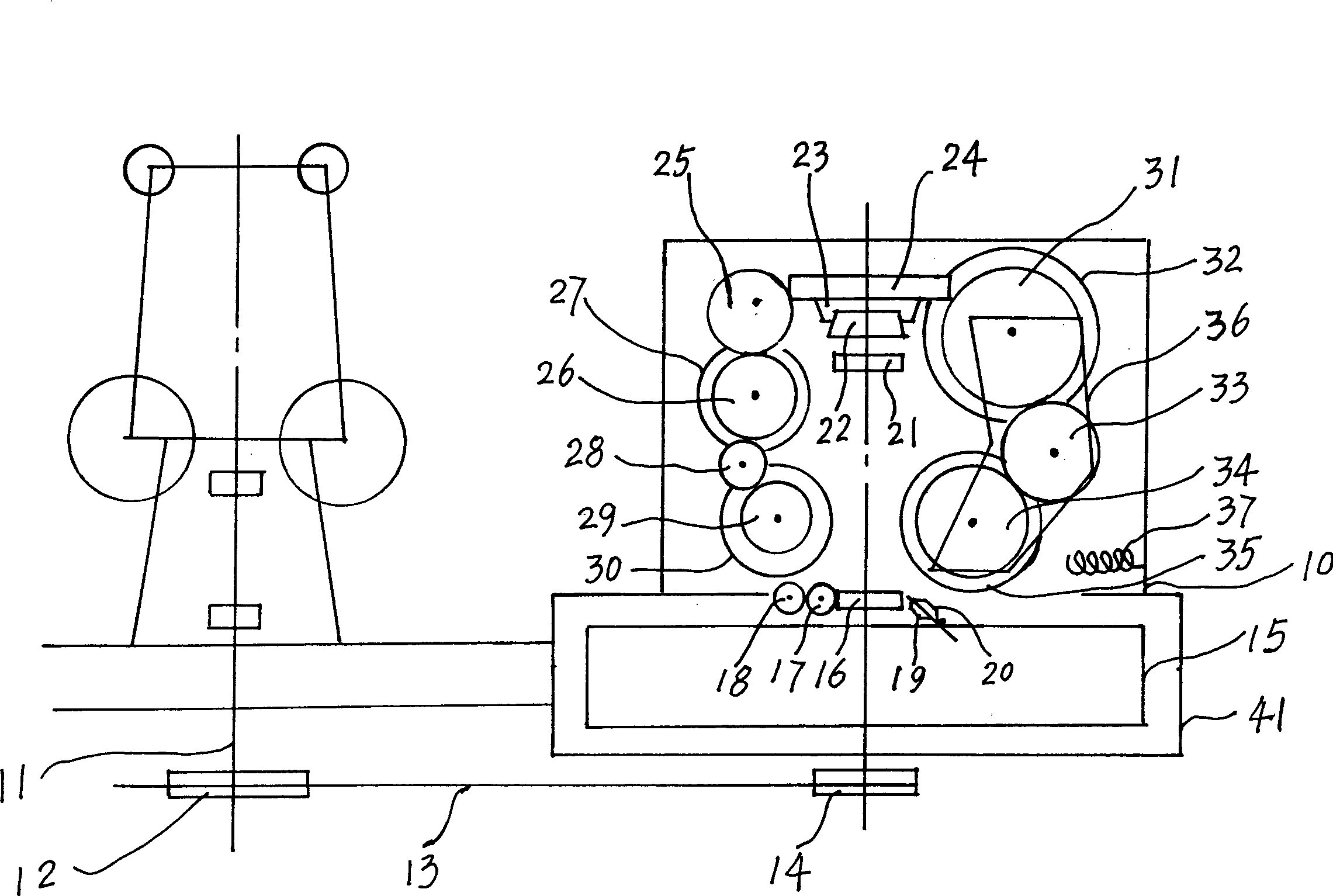

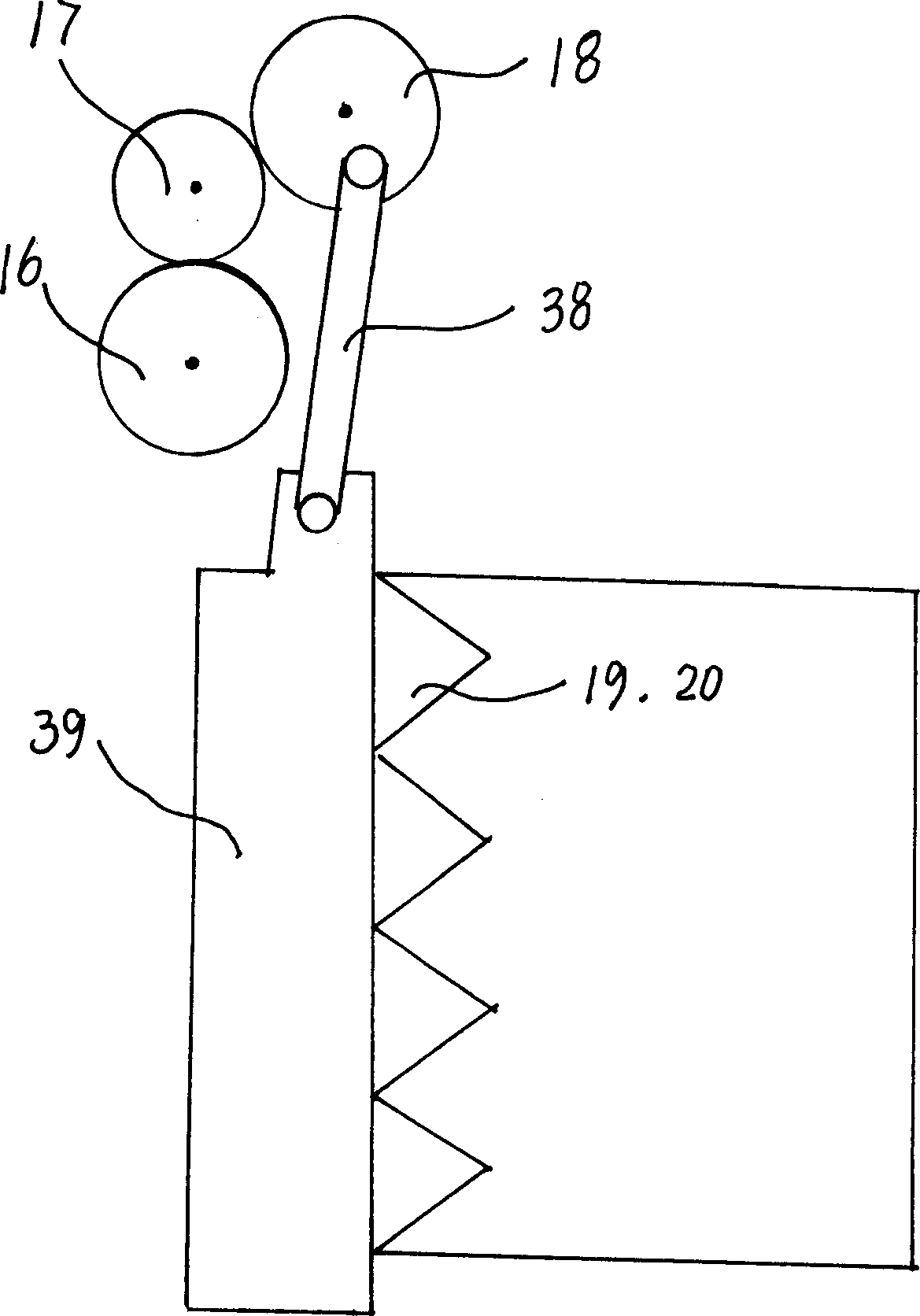

[0018] refer to figure 1 As shown, a stem-like silage feed cutting and crushing double-knife parallel cutting harvester, its external structure is mainly composed of a grain divider 1, a bridge guard 2, a chopping chamber 3, and a chopping inspection port 4, material injection port 5, suspension adjustment frame 6, rear trailer traction frame 7, protective cover 8, caster 9, frame 10 (not shown in the figure) etc. are formed, in the crop divider 1, be provided with push-down device, extend After going out, the stalk can be pushed down, and the bridge shield 2, the shield 8 and the shredding chamber 3 are provided with a mechanical transmission device and a cutting and crushing tool, and the suspension adjustment frame 6 is used to connect the hydraulic suspension and the power output shaft. The trailer traction frame 7 is used to connect the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com