Transformer and reactor with coiled core and the making process

A manufacturing method and a technology of rolling iron cores, which are applied in the manufacture of inductors/transformers/magnets, transformer/inductor cores, transformer/inductor coils/windings/connections, etc., which can solve the problems of easy pollution and prevent oil pollution , easy to connect and ensure personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The implementation of the present invention is not limited by the following examples, and the specific implementation can be determined according to the actual situation and the above-mentioned technical solutions of the present invention.

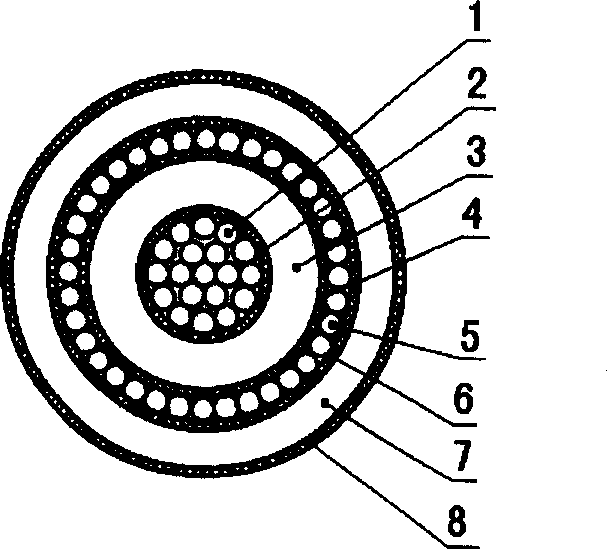

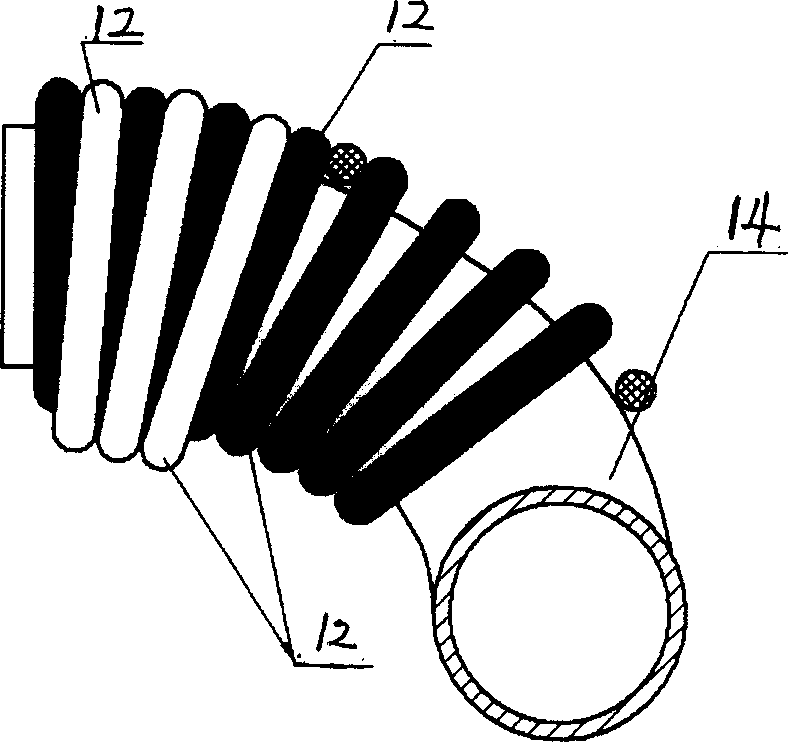

[0045] as attached Figures 3 to 12 As shown, a wound core cable winding transformer / reactor includes a wound iron core and a cable winding 12. The wound iron core is wound in the cavity of the ring frame, and the cable winding 12 is wound outside the ring frame, while the ring frame consists of It consists of less than two sections of skeleton 14, and at least one section of skeleton 14 has holes or slots 15 for piercing the iron sheet.

[0046] In the manufacturing method of the wound iron core cable winding transformer / reactor of the present invention, the wound iron core and the cable winding 12 are installed together according to the following steps: first, the cable winding 12 is pre-wound in the hole without the iron chip thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com