Self-lifting device for bridge crane

A crane and self-lifting technology, applied in cranes, trolley cranes, transportation and packaging, etc., can solve the problems of high transportation risks and higher and higher heights of the whole machine, expand the selection range of ship types, and reduce transportation and transportation risks. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

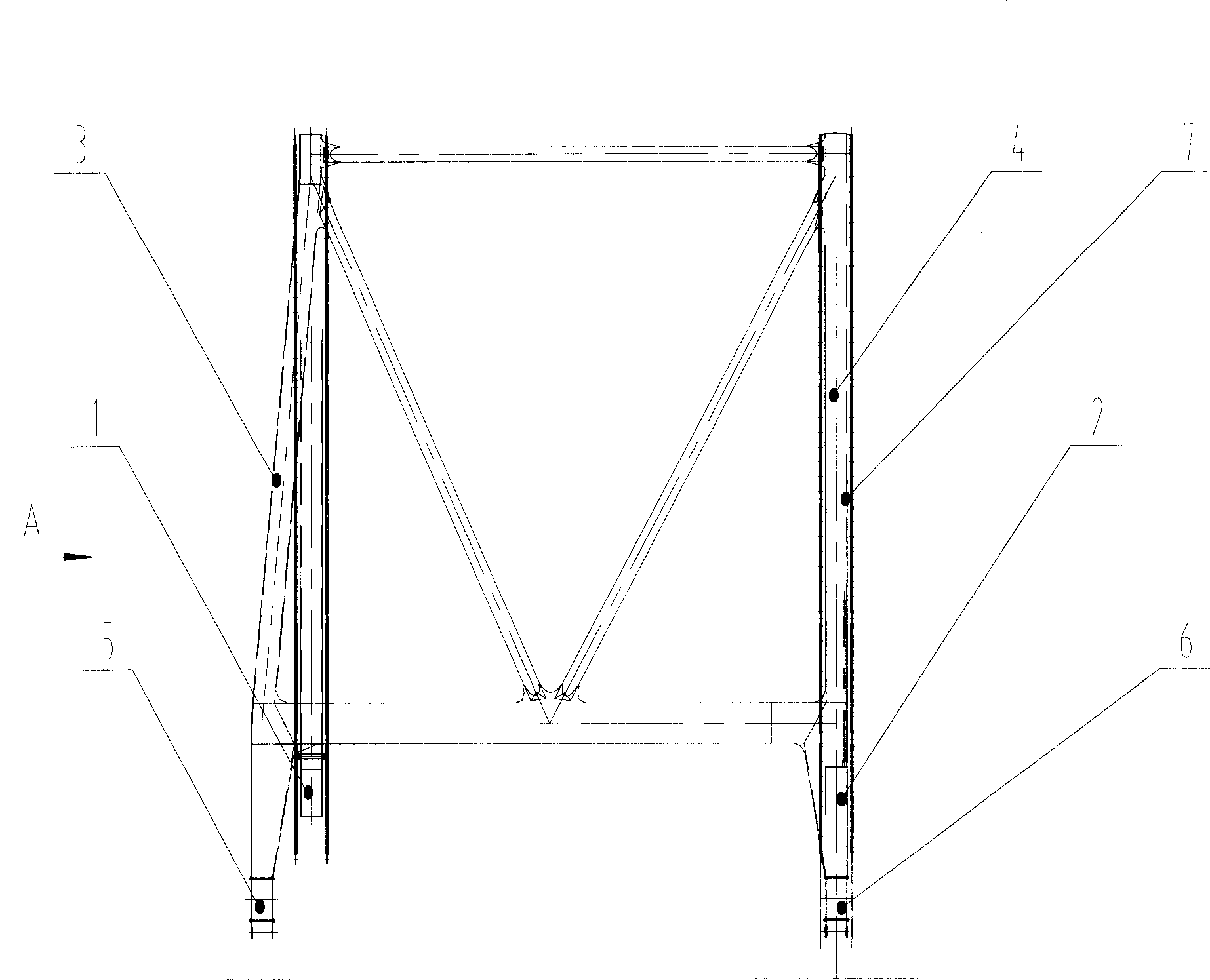

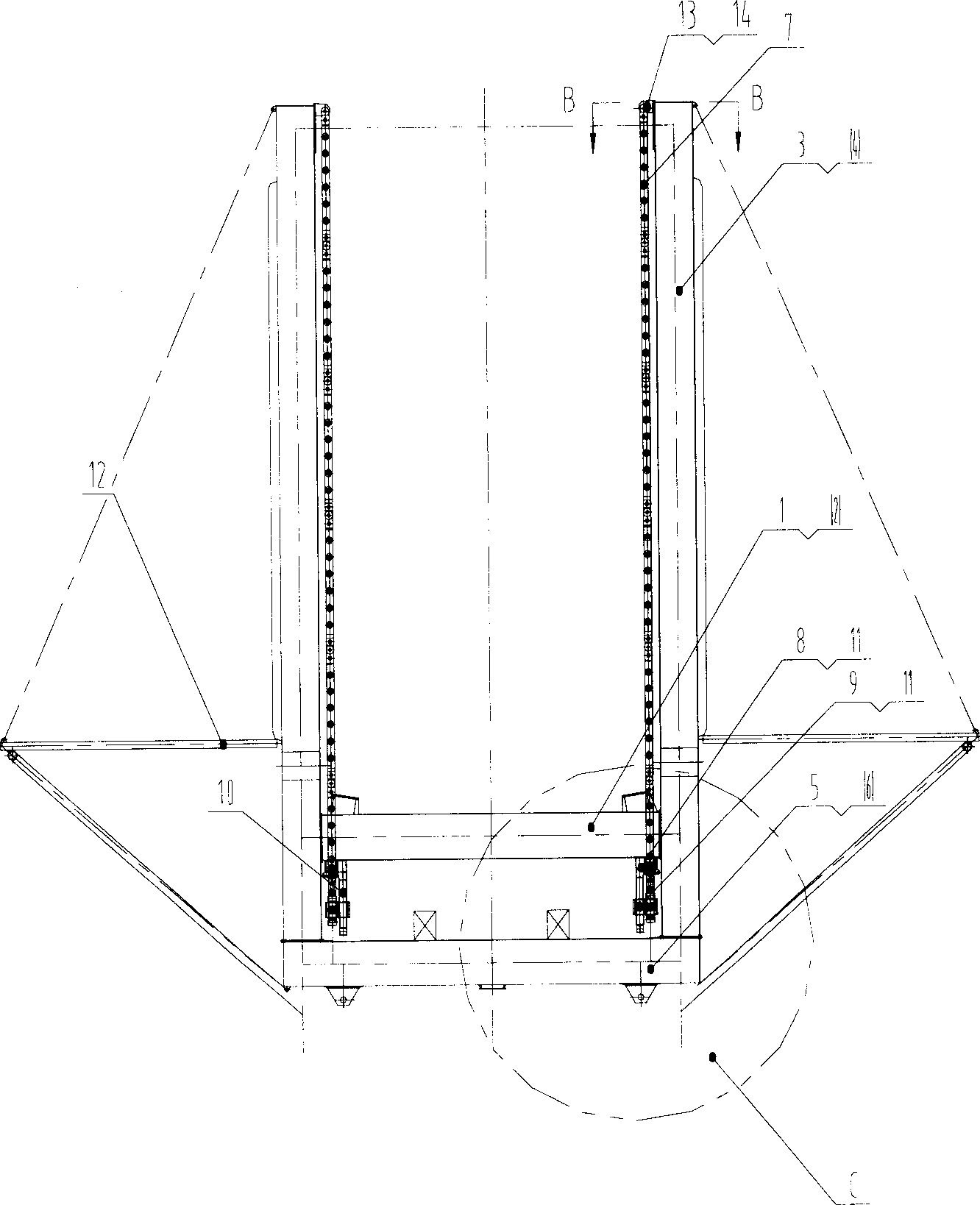

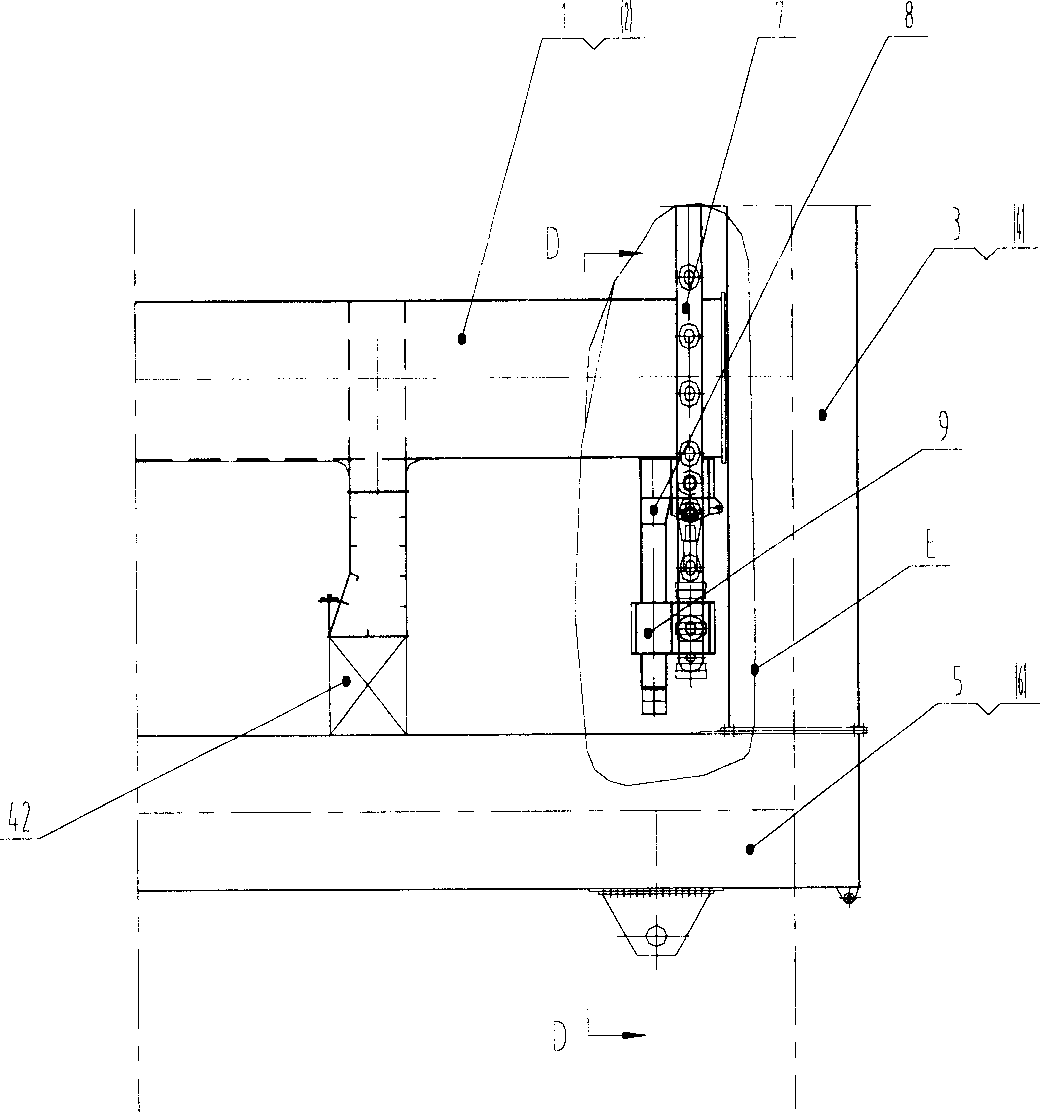

[0043] Embodiments of the invention are given below in conjunction with the accompanying drawings, and the structure and actions of the invention are further described.

[0044] Such as Figure 1-4 Shown: a self-elevating device of a bridge type crane, including the sea and land side upper beams 1 and 2 of the shore container crane, the sea and land side columns 3 and 4, and the sea and land side lower beams 5 and 6, the composition cost Invented supporting structural framework (see figure 1 ), which is characterized in that it also includes pull plate 7, pull plate beam 13, lifting lug 14, upper support frame 8, lower support frame 9, column reset support 12 (see figure 2 , 3 ), jacking cylinder 10, latch device 11 (see Figure 4 ); the connection between the upper beams 1 and 2 on the sea and land sides and the uprights 3 and 4 on the sea and land sides is separable and connected by side flanges; a tie plate is set on the top of each upright 3 and 4 on the sea and land s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com