Spiral shape multi-cavity explosion-sesisting tyre

A helical, multi-cavity technology, applied in wheel rims, vehicle parts, vehicle safety arrangements, etc., can solve problems such as traffic accidents, tire bursts, vehicles unable to drive normally, and achieve the effect of high safety factor and ensuring driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

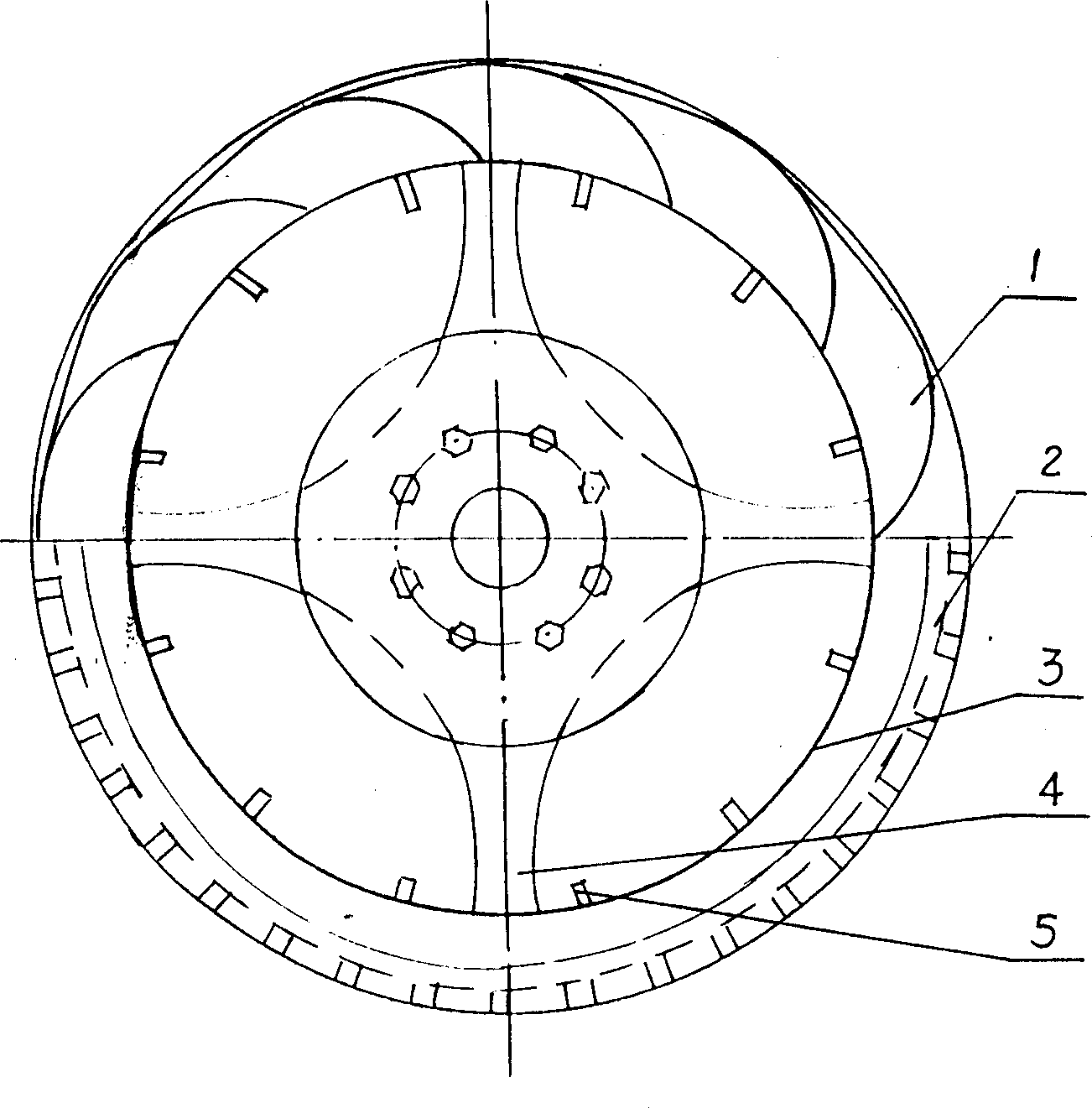

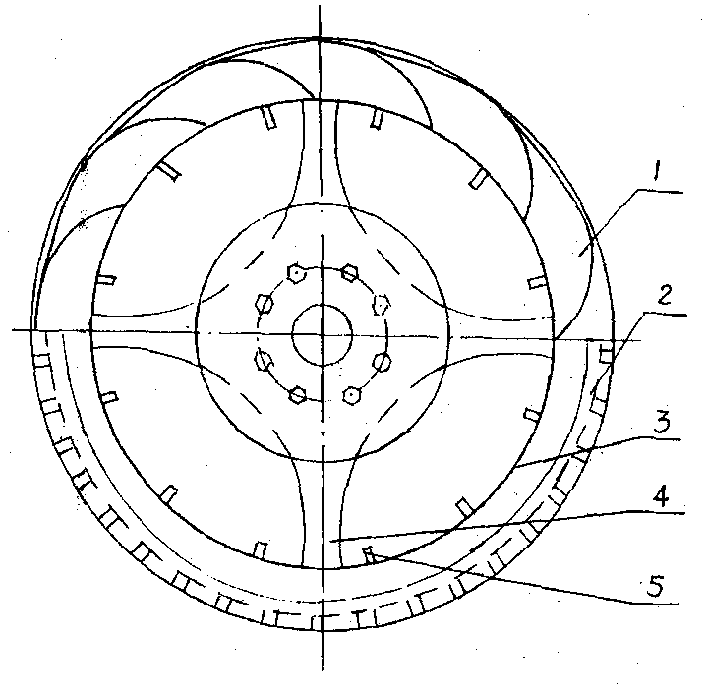

[0010] The spiral multi-gas nozzle and multi-cavity explosion-proof wheel of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. See figure 1 It is a structural schematic diagram of a spiral multi-gas nozzle and multi-cavity explosion-proof wheel, which is composed of an inner tube 1, an outer tire 2, a rim 3, a hub 4, and a spoke 5. It is characterized in that 2 to 16 independent inner tubes in a spiral shape are used 1. Air valves 6 are provided on each inner tube 1 to form independent multi-air cavities that are not communicated with each other. When one of the inner tires 1 of the motor vehicle is punctured by a pointed object or the tire pressure changes due to temperature changes and the tire bursts, the other inner tires 1 can continue to work to ensure driving safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com