Improved heat transfer tube with grooved inner surface

An inner surface and outer surface technology used in the field of heat transfer tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

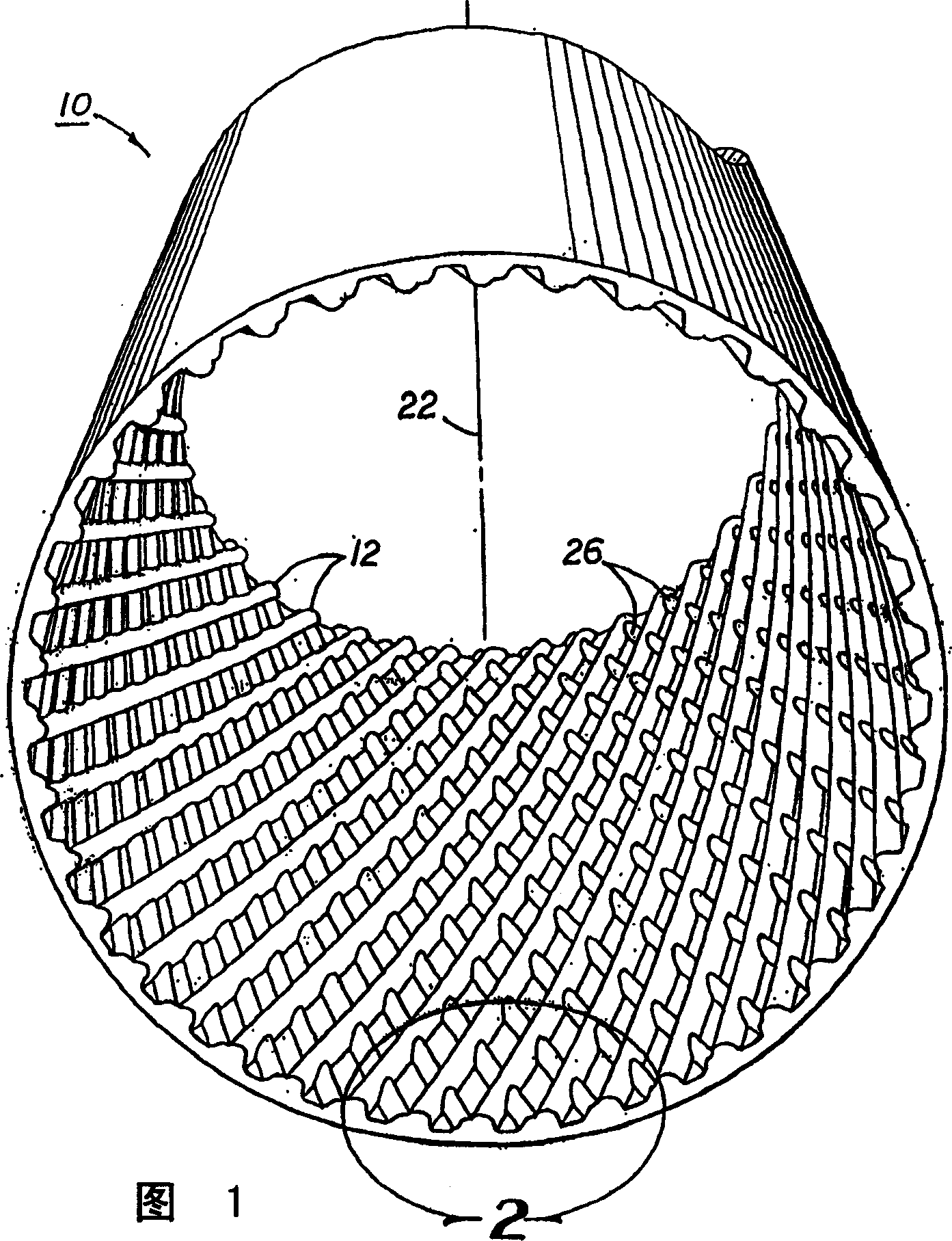

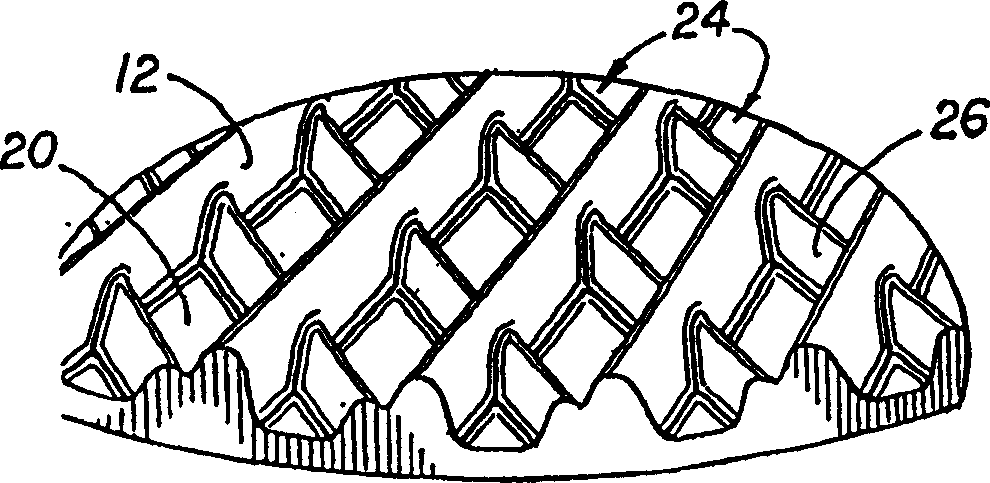

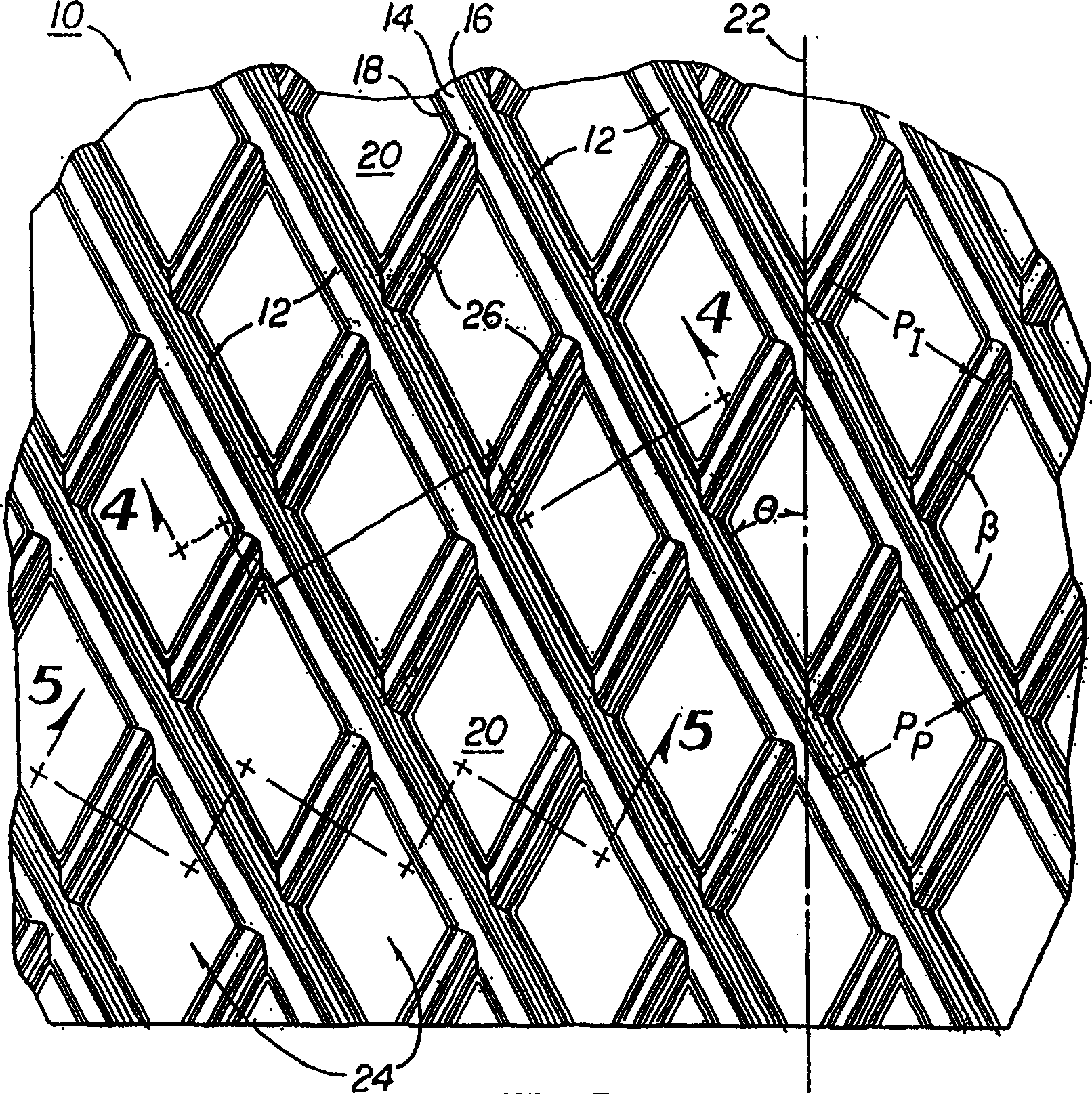

[0053] Similar to prior art patterns, one embodiment of the inner surface pattern of the tube 10 of the present invention is shown in FIGS. The cross-sectional shape of the basic fin 12 can be assumed as Figure 6-11 Any shape disclosed, but preferably a triangular shape with sloped straight sides 14, rounded apex 16, and rounded edge 18 at the junction of straight side 14 and inner surface 20 of tube 10 (see Figure 4 ). Basic fin height H p It can vary depending on the diameter of the tube 10 and the particular application, but is preferably between 0.004-0.02 inches. like image 3 As shown, the base fins 12 may be positioned at a base fin angle Θ relative to the longitudinal axis 22 of the tube 10, the angle being between 0°-90°. The angle θ is preferably between 5°-50°, more preferably between 5°-30°. Finally, the number of elementary fins 12 positioned along the inner surface 20 of the tube 10, and the pitch P of the elementary fins p (determined as the distance mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com