Mass center method for adjusting core making automatic end to end joint for wave-guide and optical fiber

An automatic docking and automatic adjustment technology, applied in the field of optical communication, can solve problems such as poor repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Optical fiber - automatic core adjustment of optical fiber and its results:

[0054] A commercially available flat-polished single-mode fiber patch cord was used as the standard waveguide in the experiment. Since the mode field distribution of single-mode fibers is very standardized, the coupling test between single-mode fibers can eliminate the influence of waveguide defects and objectively reflect the characteristics of the software and hardware of the core alignment system. Install two single-mode optical fibers with clean and dry end faces on the bracket of the core alignment instrument, and place a small amount of refractive index matching liquid between the end faces of the two optical fibers. The refractive index of the matching liquid is 1.445 and 1.444 at wavelengths of 1310nm and 1550nm, respectively. The refractive index difference with the silica fiber core is less than 0.01, and the reflection loss is less than -50dB. The transmittances of the matching liq...

Embodiment 2

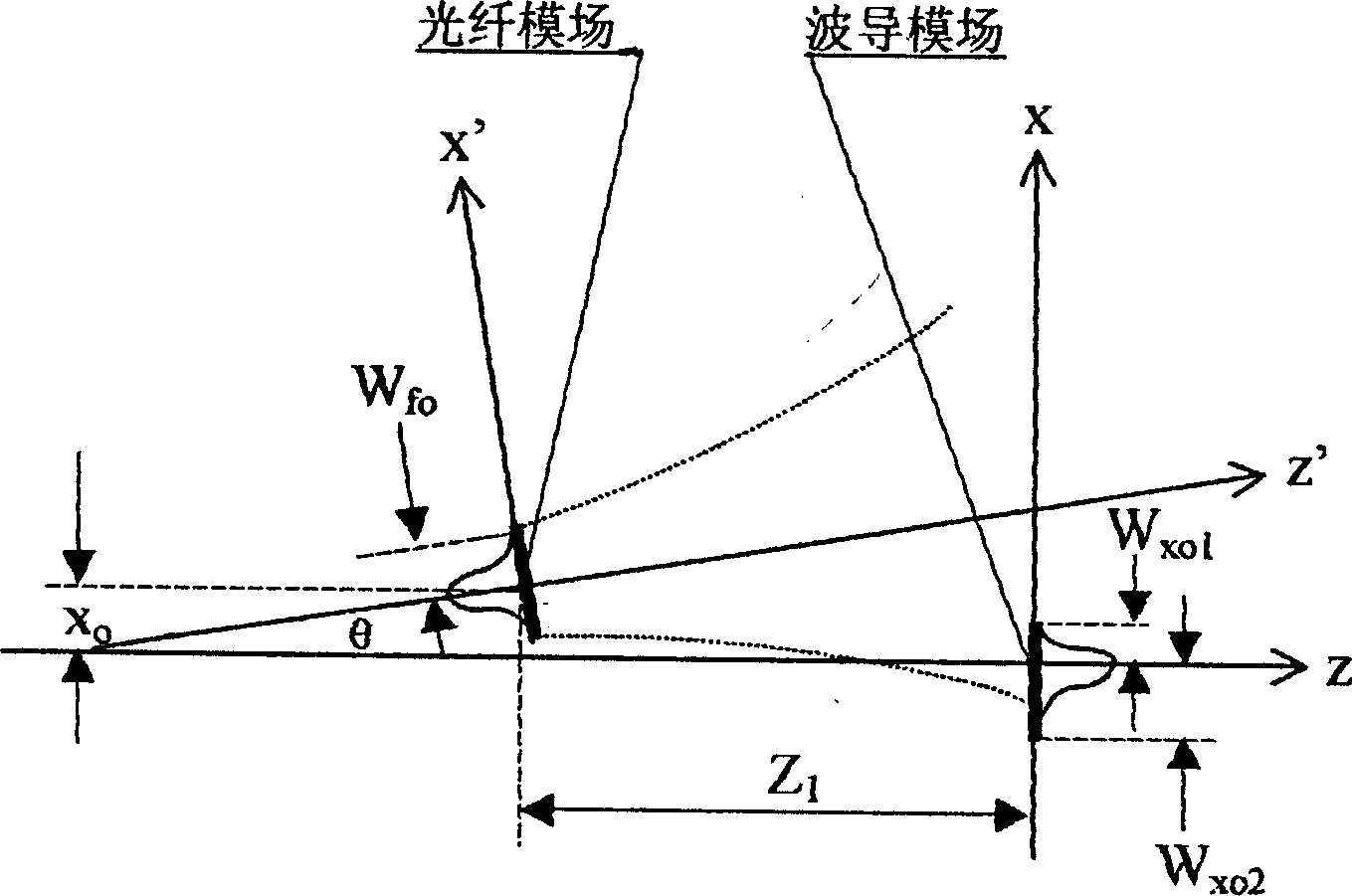

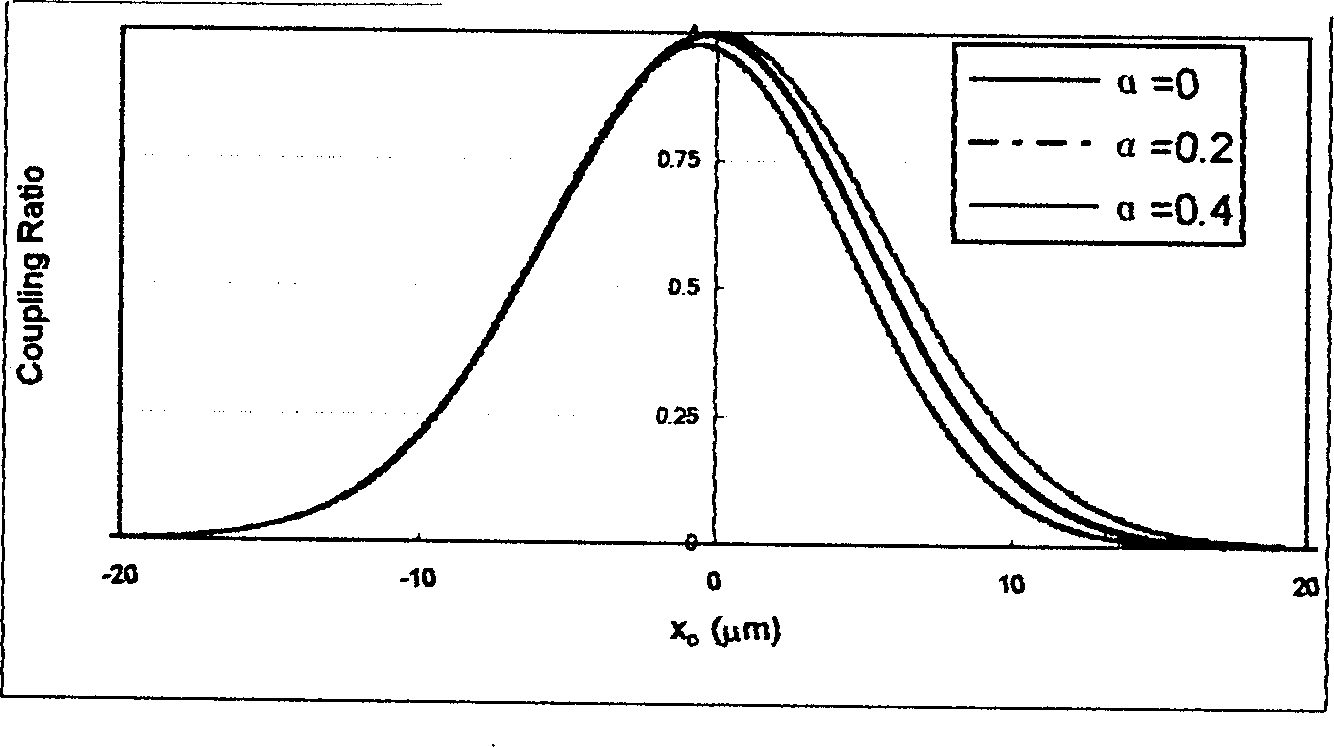

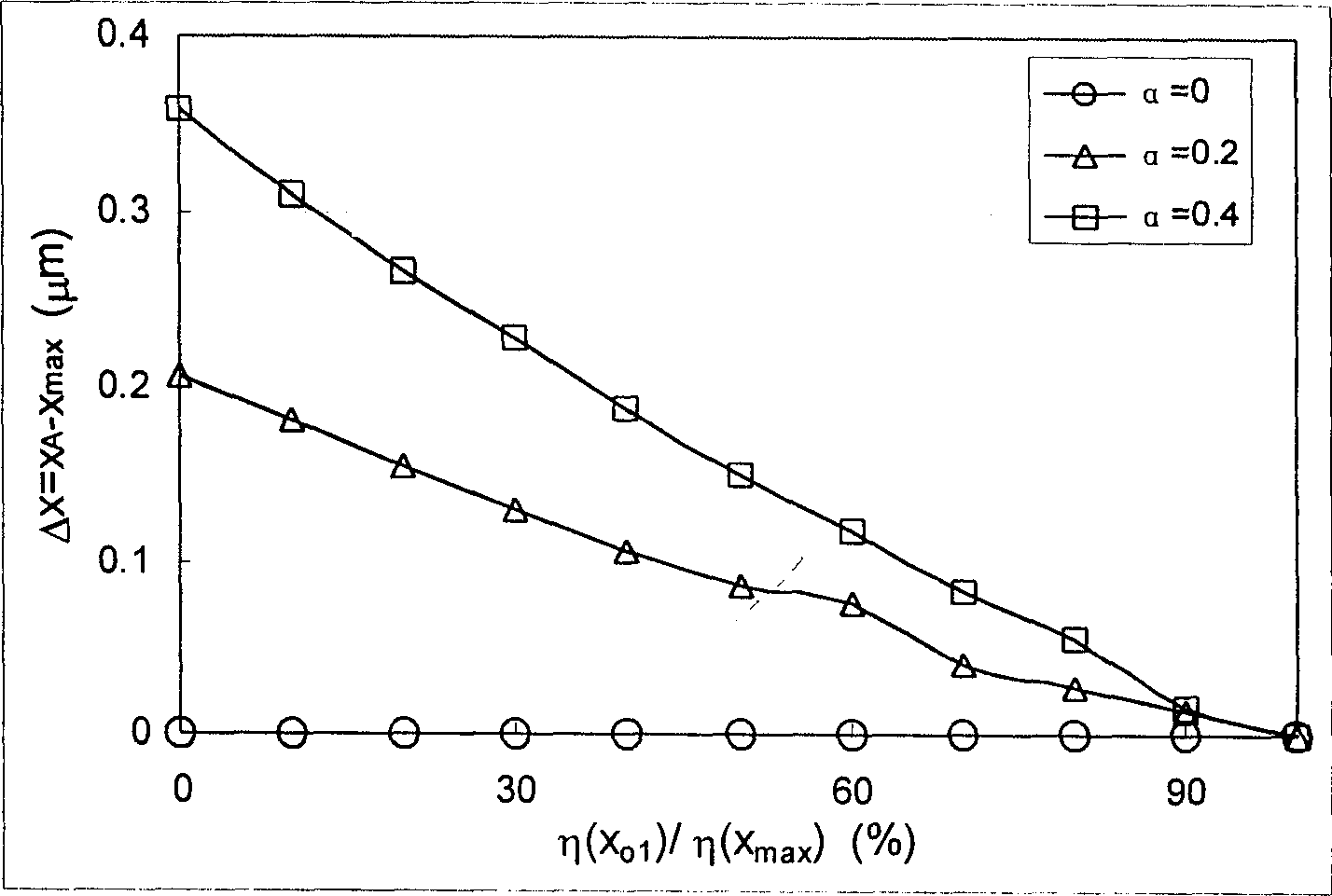

[0058] Fiber-waveguide-fiber automatic core alignment and its results:

[0059] The optical waveguide uses quartz-based SiO produced by NHK Corporation of Japan 2 Buried single-mode strip waveguide, the design value of the waveguide core section size is 8×8μm 2 , The relative refractive index difference Δ = 0.3%, both ends of the plane grinding. The input and output ends are respectively connected to single-mode optical fibers, and a refractive index matching liquid is arranged between the end faces. The rough adjustment process is basically the same as the fiber-to-fiber one above. Since there is a pair of couplings at both ends of the waveguide, the initial light adjustment is easy to judge by using 632.8nm visible light. After the light is passed between the fiber-waveguide-fiber, the feedback channel between the computer and the power meter enters the operational state, and at this time, the input light is changed to near-infrared light. The automatic alignment at both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com