Method for coating active component cellular carrier

A honeycomb carrier, active component technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as uneven coating, and achieve the effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] This example illustrates the method provided by the invention.

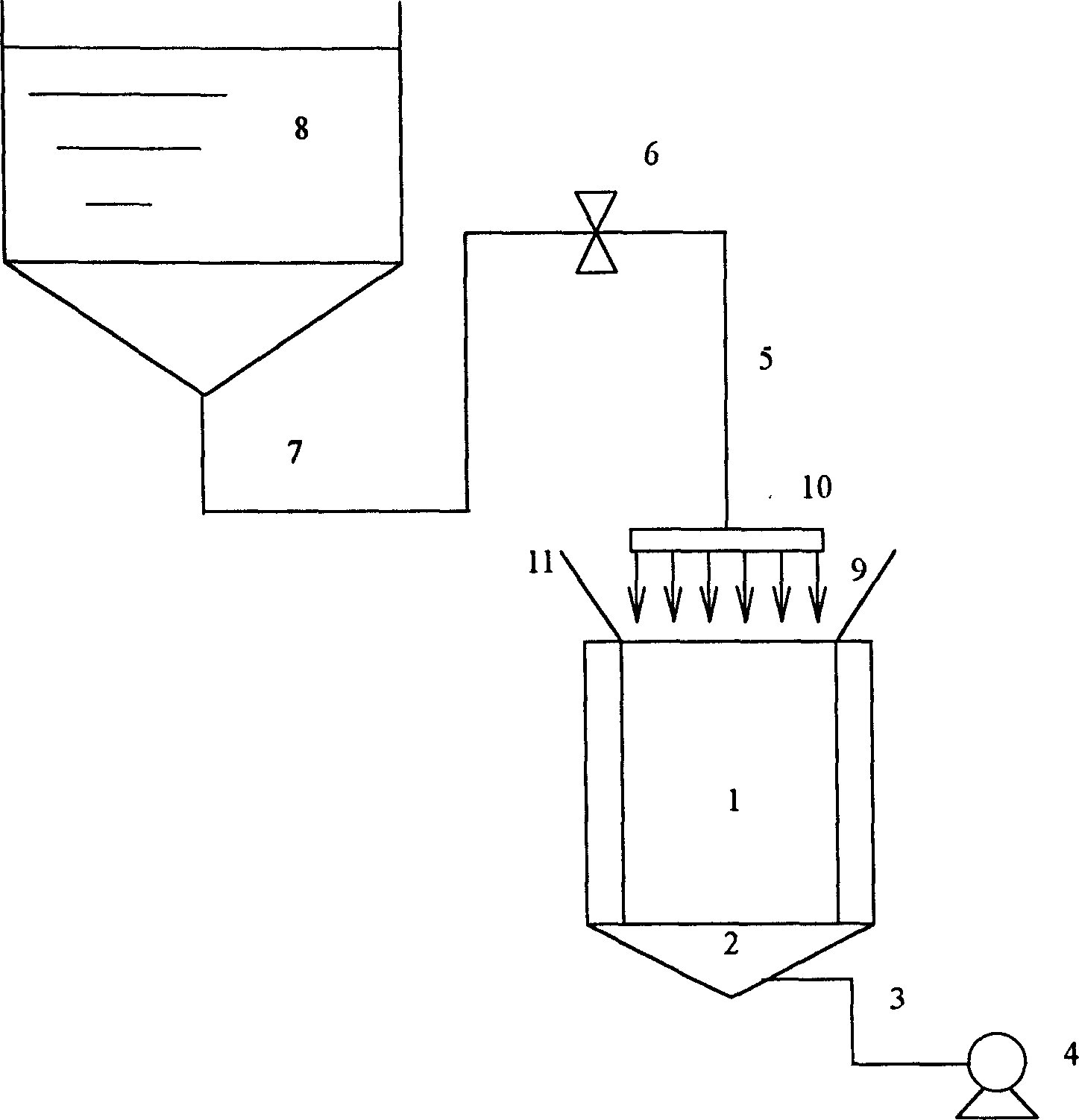

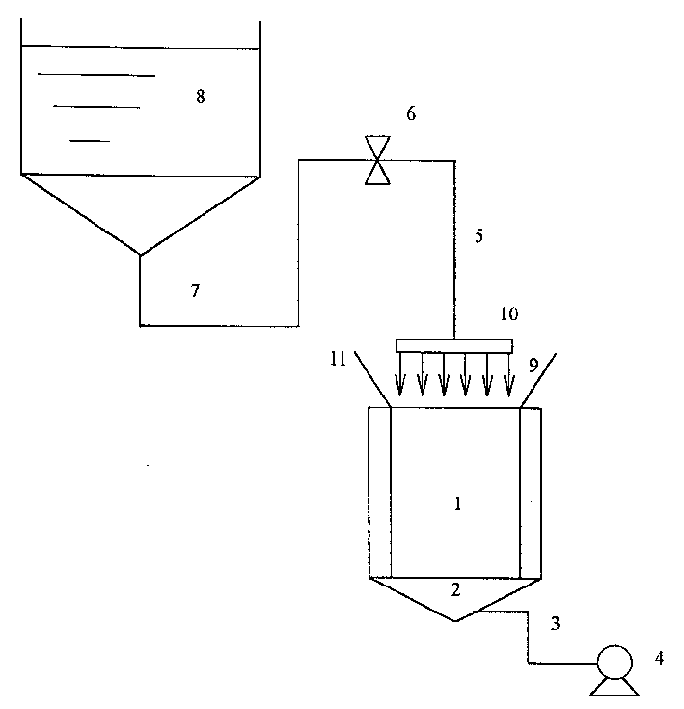

[0027] Such as figure 1 As shown, (1) the honeycomb carrier 1 with particle trapping function is placed vertically, and the space 2 at the lower end of the carrier 1 is sealed. The carrier 1 is a cylindrical ceramic carrier with a weight of 1312 grams and a cross-sectional area of 162.24 cm 2 , the height is 15.24 cm, and the number of pores on the cross-section is 15.5 pores / cm 2 , the cross-sectional area of the square air hole is 16.0mm 2 (the side length is 4.0 millimeters), the volume of the carrier is 2473 milliliters, each pore is blocked at one end, and the water pore volume is 494.6 milliliters.

[0028] Turn on the vacuum pump 4, vacuumize the confined space 2 through the pipeline 3, and when the pressure reaches 70 kPa, open the valve 6, the slurry 9 is ejected from the nozzle 10, and the slurry 9 enters from the storage tank 8 through the pipeline 7, valve 6 and pipeline 5 Nozzle10.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com