Long-stator iron core electric performance testing device

A technology for electrical performance and testing devices, applied in the field of measuring instruments, to reduce debugging time, ensure normal operation, and reduce laying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

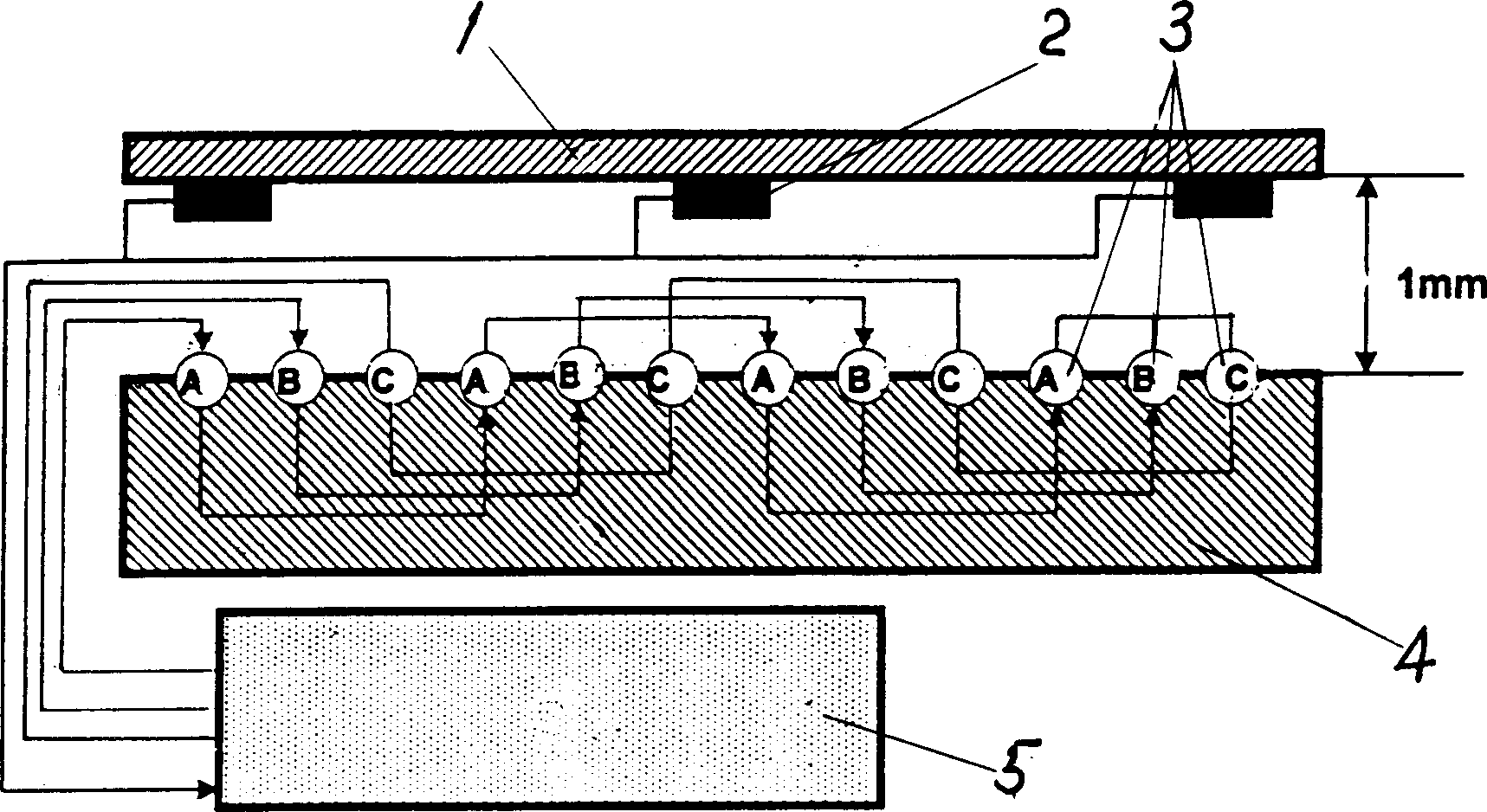

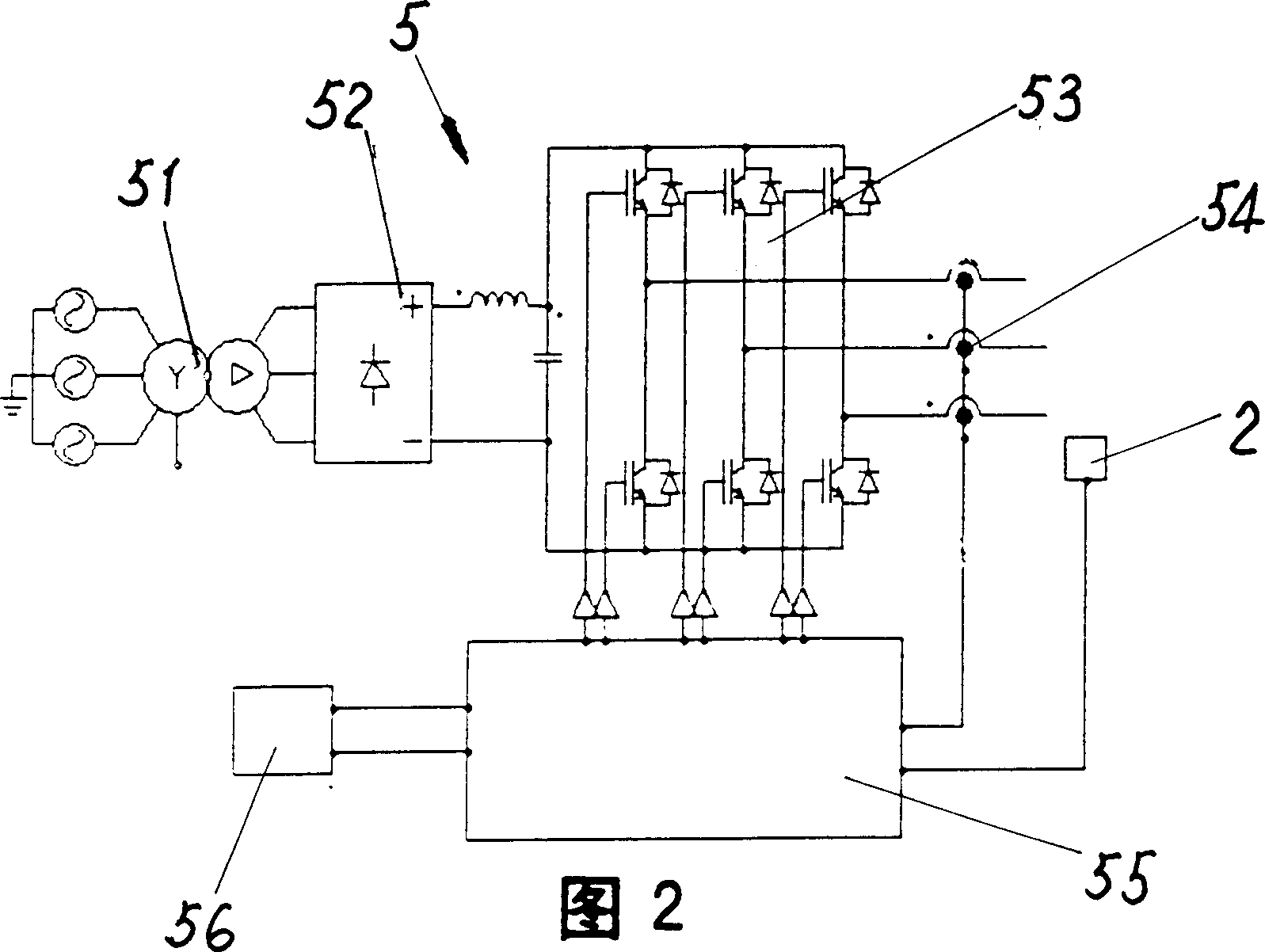

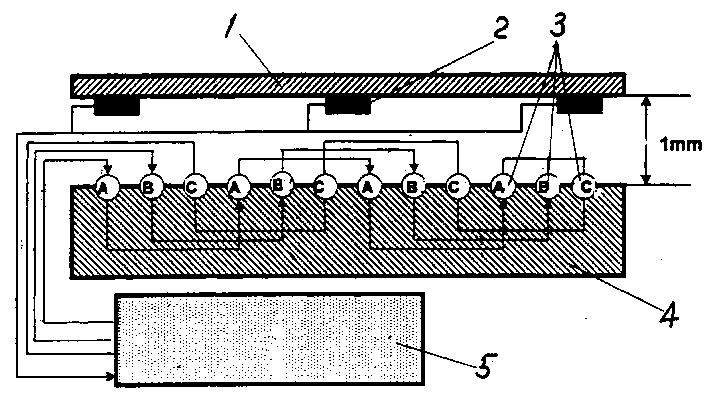

[0013] see figure 1 . The present invention is provided with a magnetic induction block 1 , a magnetic flux sensor 2 , a three-phase armature winding 3 and a measurement control system 5 . The magnetic induction block 1 is a whole ferromagnetic material; or it is composed of laminated sheets of ferromagnetic material, such as silicon steel sheets. The magnetic flux sensor 2 is a magnetic flux sensor utilizing the Hall effect, it is arranged on the magnetic induction block 1, and its output end is electrically connected with the measurement control system 5 by wires. One end of the three-phase (A, B, C) armature winding 3 is short-circuited, and the other end is electrically connected to the measurement control system 5 respectively. The measurement and control system 5 (see Figure 2) includes a transformer 51, a rectifier 52, an inverter 53 and a three-phase current closed-loop control system 55, which is a current with an effective value of 0-300 amperes and a frequency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com