Reciprocating movement compressor

A reciprocating motion and compressor technology, which is applied in the field of compressors, can solve problems such as impact, lubricating oil suction cannot be carried out smoothly, and increased oil circuit resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

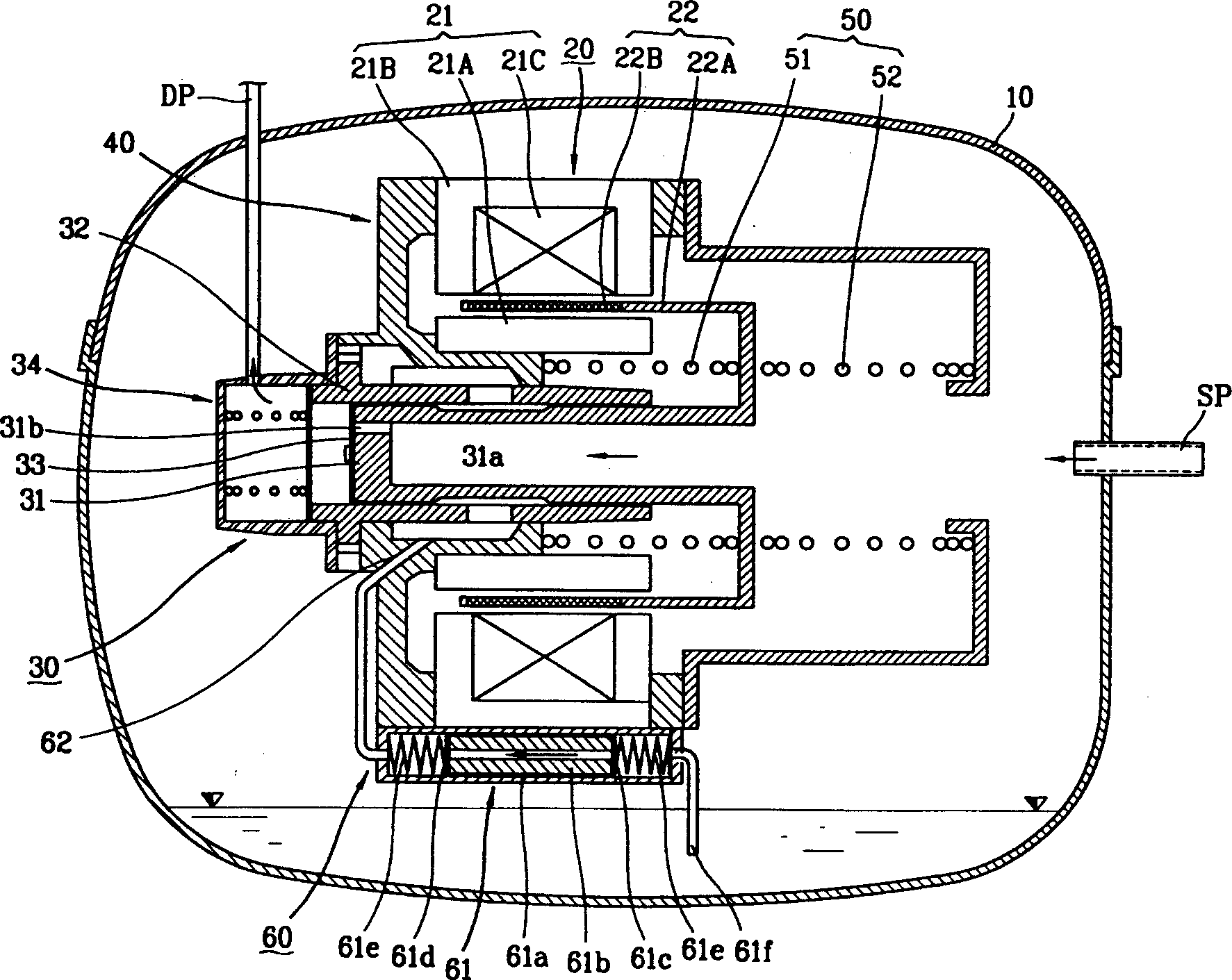

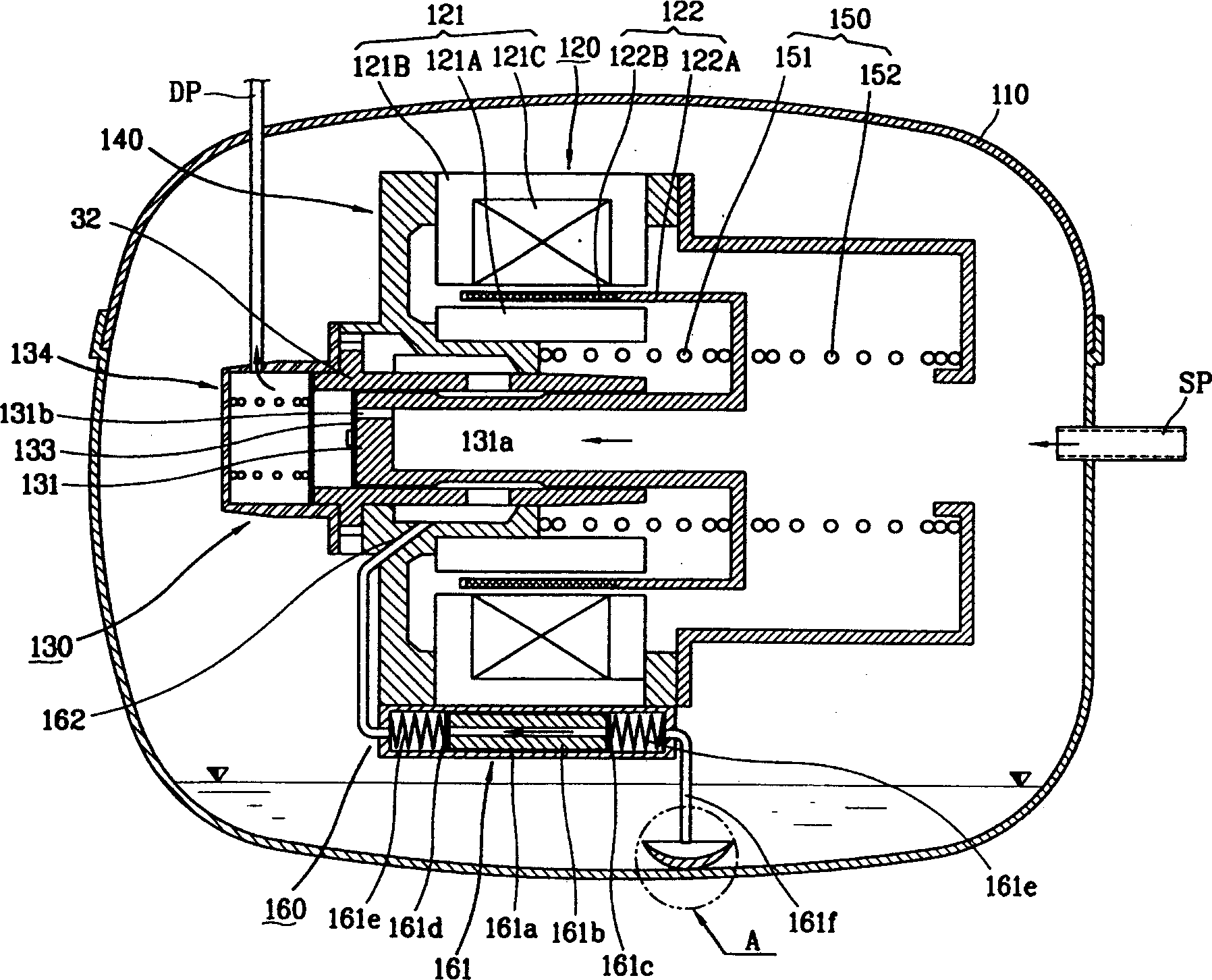

[0037] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention will be described in detail as follows.

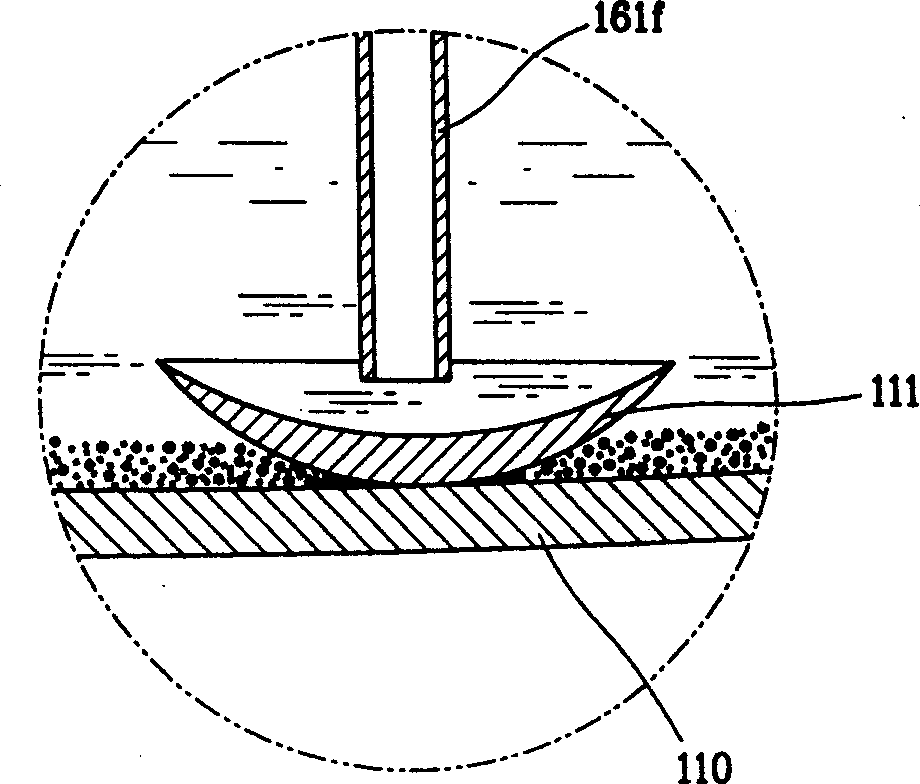

[0038] 110. Airtight container 111. Shielding part

[0039] 120. Reciprocating motor 121. Stator

[0040] 122. Rotor 130. Compression part

[0041] 140. Frame part 150. Spring part

[0042] 160. Lubricating oil supply department 161. Lubricating oil pumping department

[0043] 162. Lubricating oil supply flow path 161f. Lubricating oil suction pipe

[0044] see figure 2 , image 3 , Figure 4 As shown, the reciprocating compressor of the present invention has the following structure: the reciprocating motor 120 is arranged inside the airtight container 110 with a certain amount of lubricating oil, and the frame 40 supports the compression part 130 combined with the reciprocating motor 120; The oil supply unit 160 is attached to the frame unit 140 , and supplies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com