Decomposition catalyst for nitrous oxide, process for producing the same and process for decomposing nitrous oxide

A nitrous oxide and catalyst technology, applied in the direction of nitrous oxide capture, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of reduced specific surface area and reduced catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

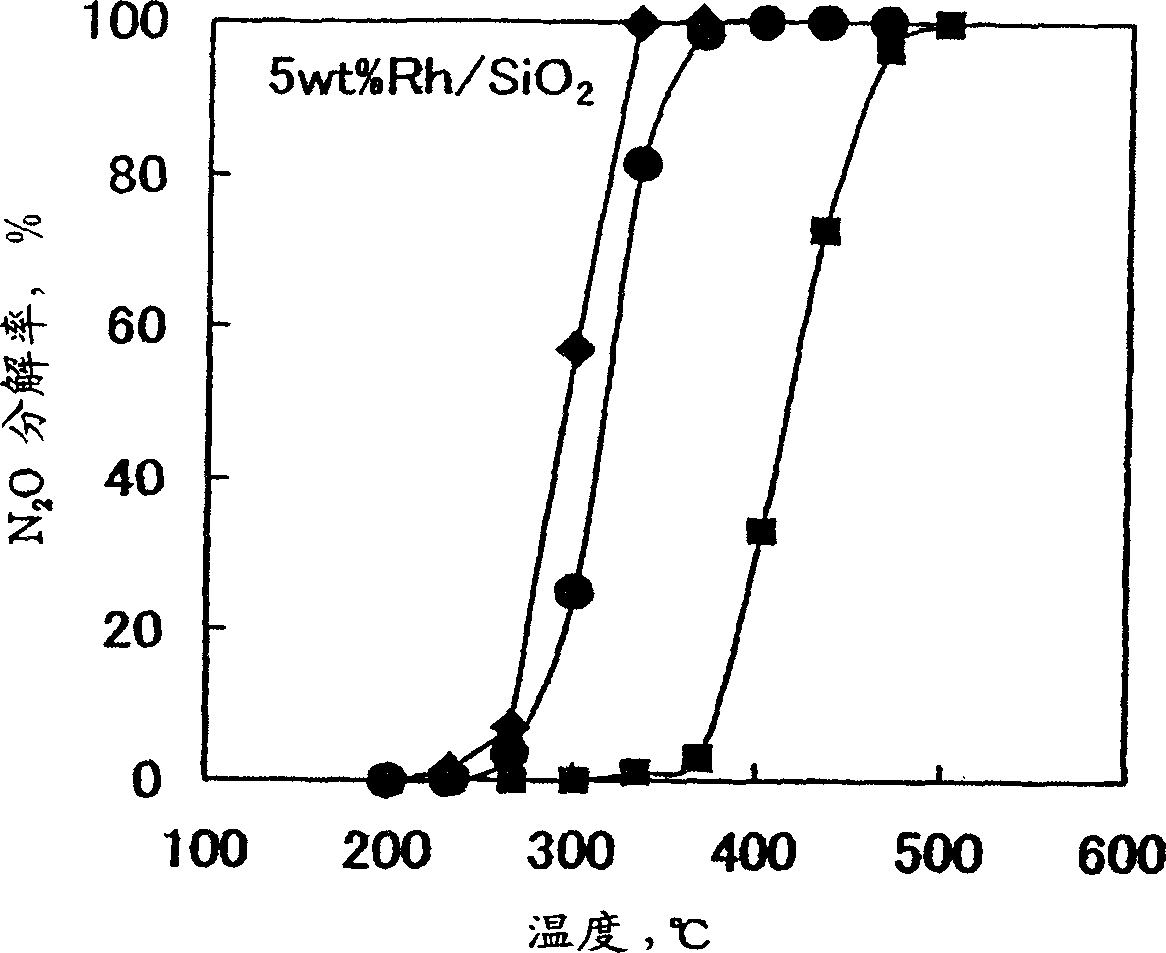

Embodiment 1

[0113] With 1.84g distilled water and 1.32g, 21.4% rhodium nitrate solution (Rh(NO 3 ) 3 aqueous solution) mixed. To this was added 2.04 g of a silica carrier (JRC-SIO-4, see Nippon Shokubai Gakkai, Shokubai (Catalyst) ), after the entire amount has been impregnated, the carrier is dried in a 90°C hot bath. The obtained carrier was dried in air at 110° C. for 12 hours, and then calcined at 650° C. for 2 hours to obtain Catalyst 1 in which 5% by mass rhodium (Rh) was supported on the silica carrier. Embodiment 2: the preparation of catalyst

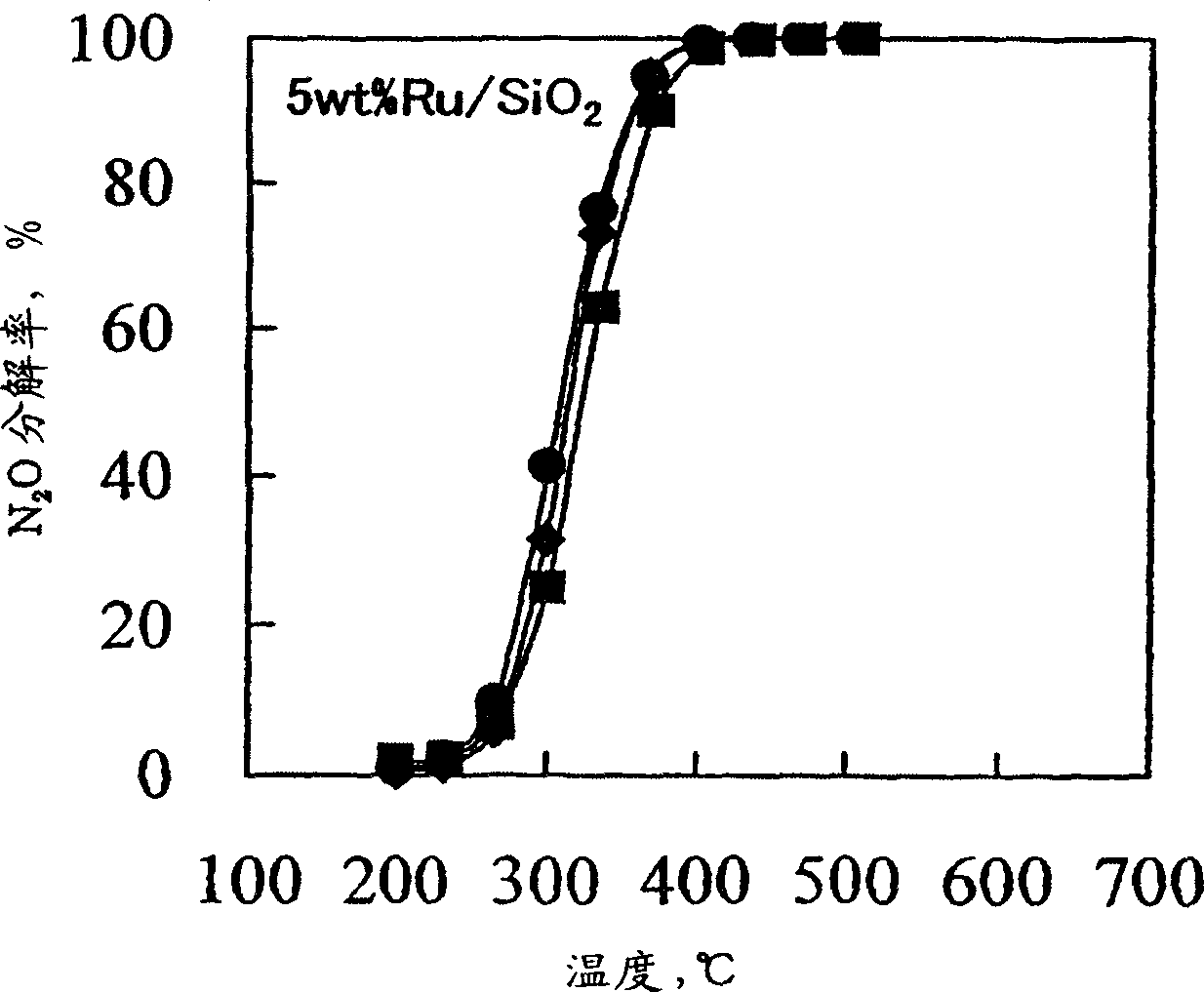

Embodiment 2

[0114] Catalyst 2 was prepared in the same manner as in Example 1, but using 0.99g of 31.4% ruthenium nitrosyl nitrate solution (Ru(NO)(NO 3 ) 3 aqueous solution). In the obtained catalyst 2, 5% by mass of ruthenium (Ru) was supported on a silica carrier. Embodiment 3: the preparation of catalyst

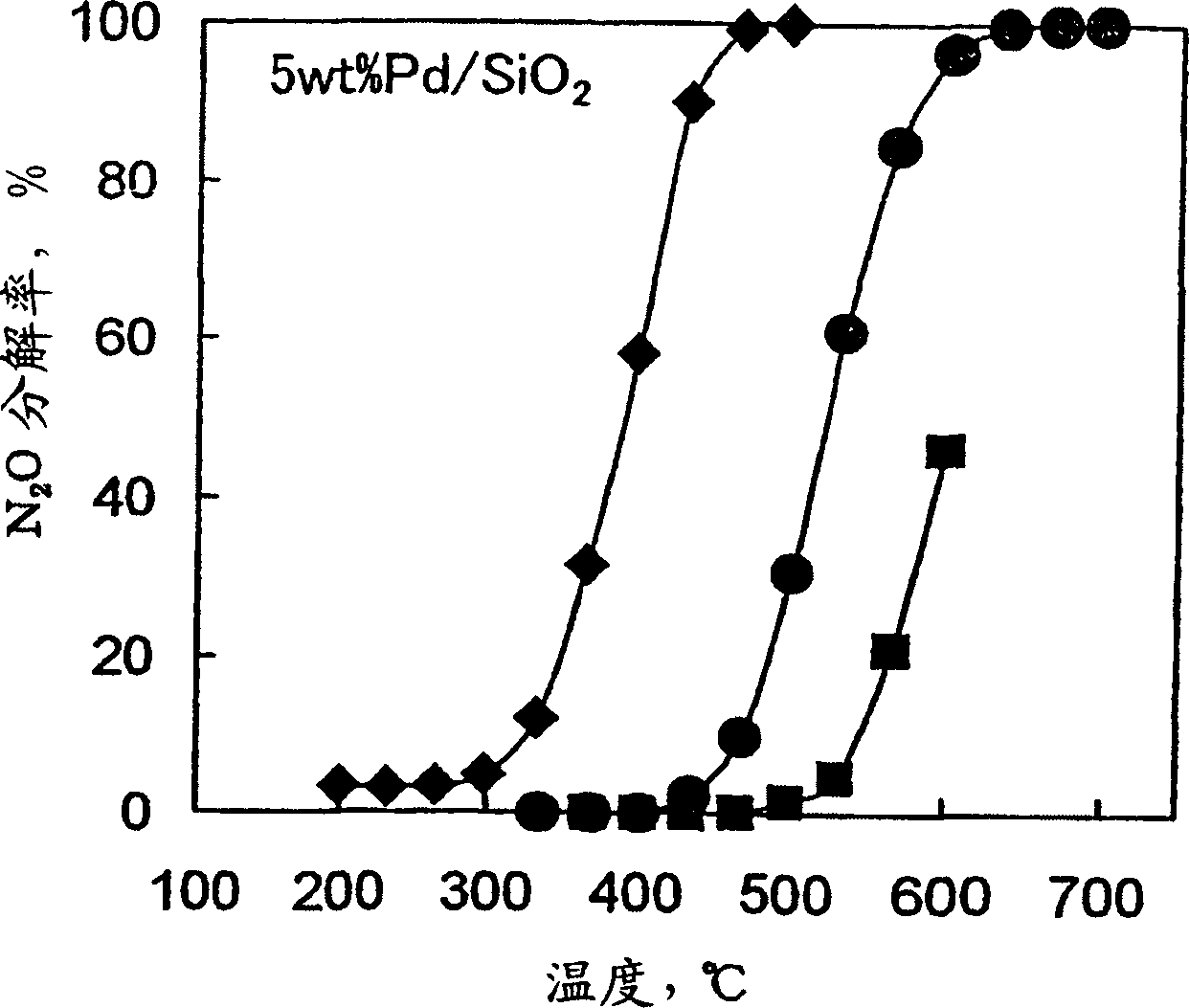

Embodiment 3

[0115] Catalyst 3 was prepared in the same manner as in Example 1, but 0.43g of 52.2% palladium nitrate solution (Pd(NO 3 ) 3 aqueous solution). In the obtained catalyst 3, 5% by mass of palladium (Pd) was supported on a silica carrier. Embodiment 4: the preparation of catalyst

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com