Molding method and mold for shoe sole of foamed colored ethylene-vinyl acetate copolymer

A technology of vinyl acetate copolymerization and molding method, which is applied to other household appliances, footwear, household appliances, etc., which can solve problems such as defective products, difficult operation, burns, etc., and achieve the effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] For convenience of description, in the following embodiments, the same components are denoted by the same reference numerals.

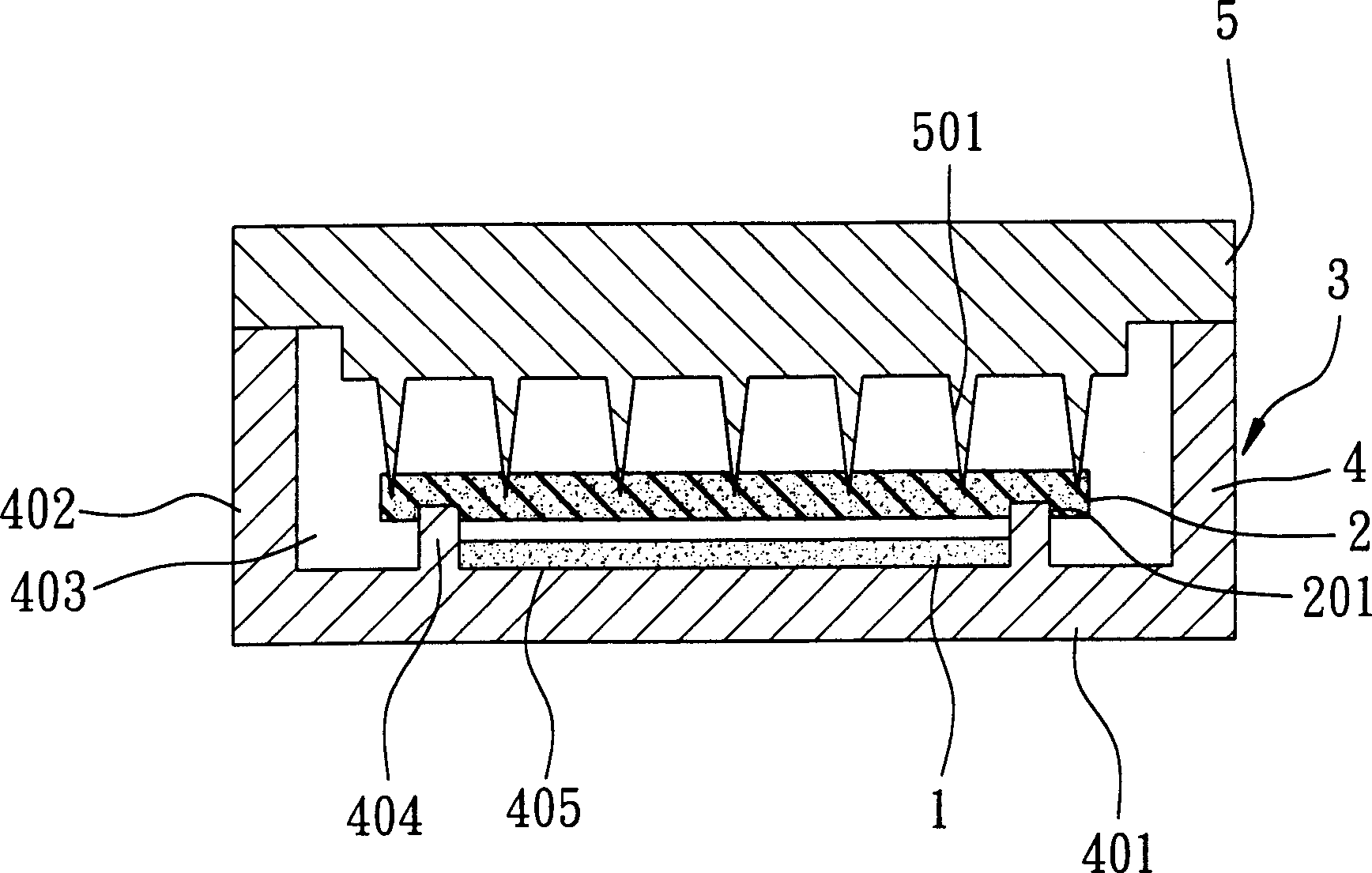

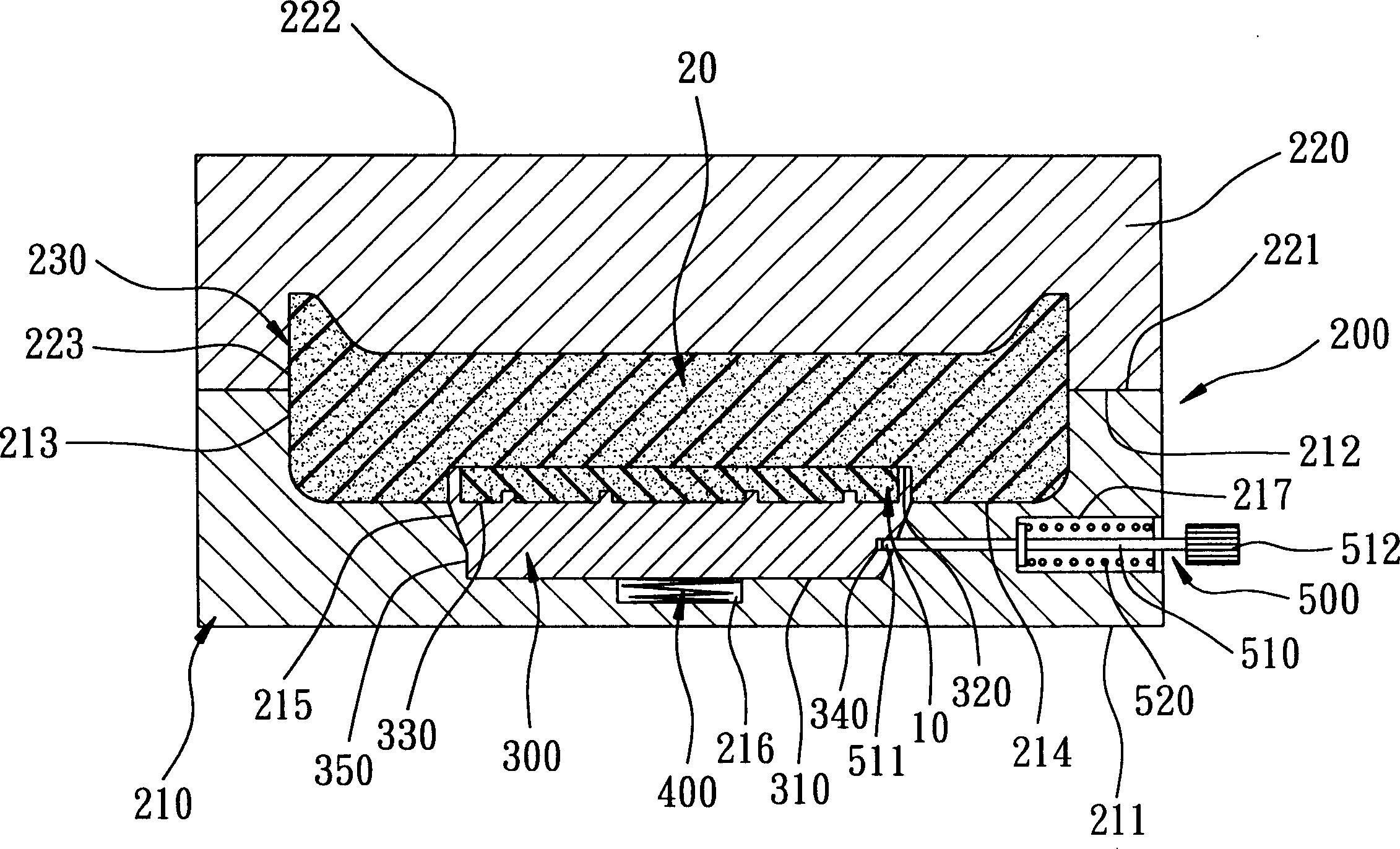

[0034] Such as image 3 As shown, the first embodiment of the multi-color ethylene-vinyl acetate copolymer foaming shoe sole forming mold of the present invention can provide at least one trim blank 10 and a large bottom blank heated to the melting point and not yet cross-linked and foamed. The materials 20 are welded to each other, and undergo cross-linking and foaming reactions. The trim blank 10 and the outsole blank 20 can be the same material (ethylene-vinyl acetate copolymer), different hardness, and different colors, so as to make a multi-color foaming sole. The mold includes a master mold 200, at least one sub-mold 300 that can be detachably set and positioned inside the master mold 200, at least one elastic element 400 that can push and lift the sub-mould 300, and a sub-mold that can make the sub-mold 300 The mold 300 is positioned b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com