Cutting tool capable of changing knife head and knife head capable of installing on said cutting tool

A cutting tool and replaceable technology, which is applied in the direction of manufacturing tools, accessories of tool holders, and tools used in lathes, etc., can solve the problems of the cutting head falling off, the rigidity cannot be guaranteed, and the installation state of the cutting head is poor. Stability, increased rigidity, and the effect of maintaining a stable installation state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097]Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

[0098] First, a first embodiment of the present invention will be described.

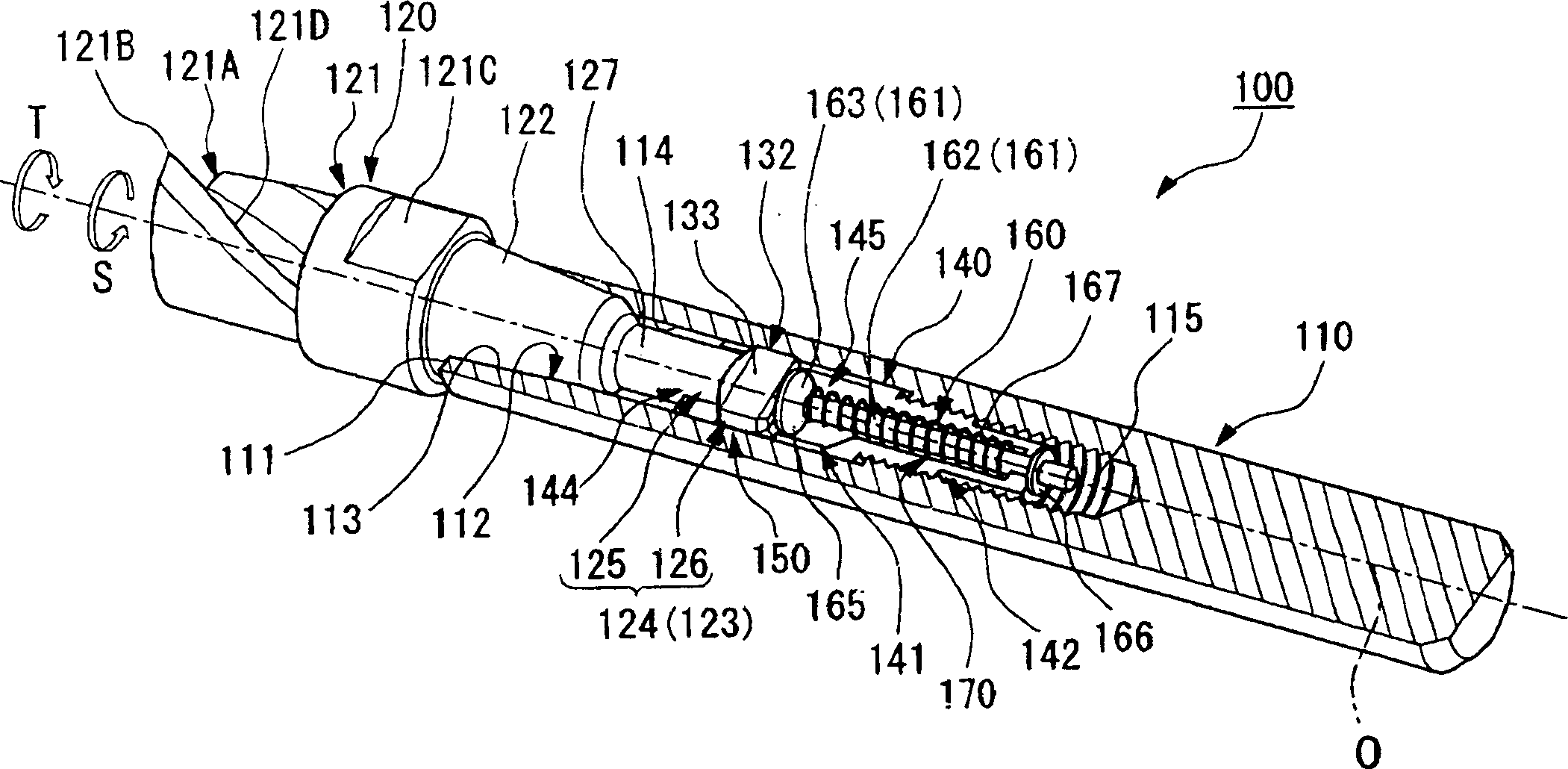

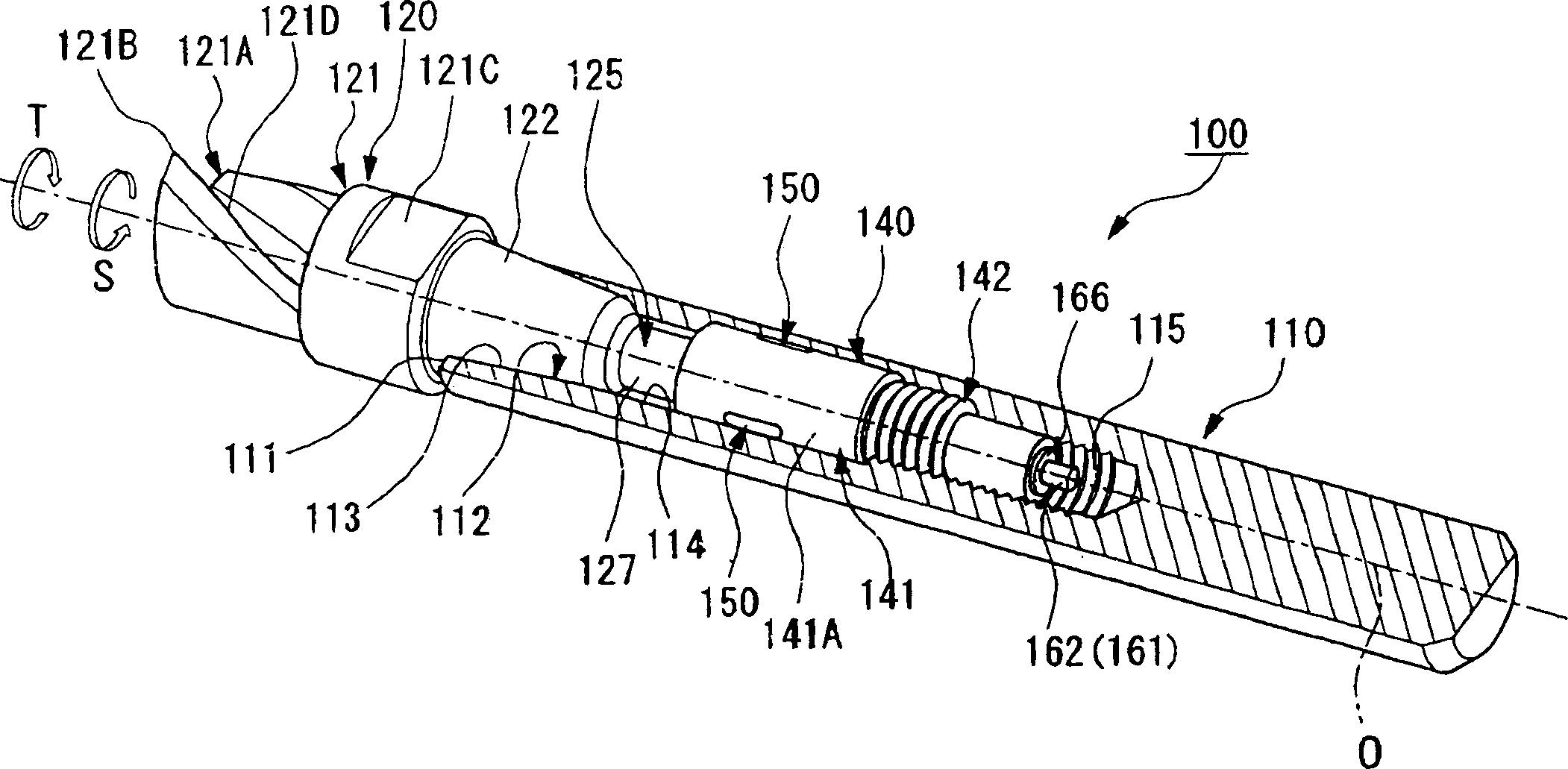

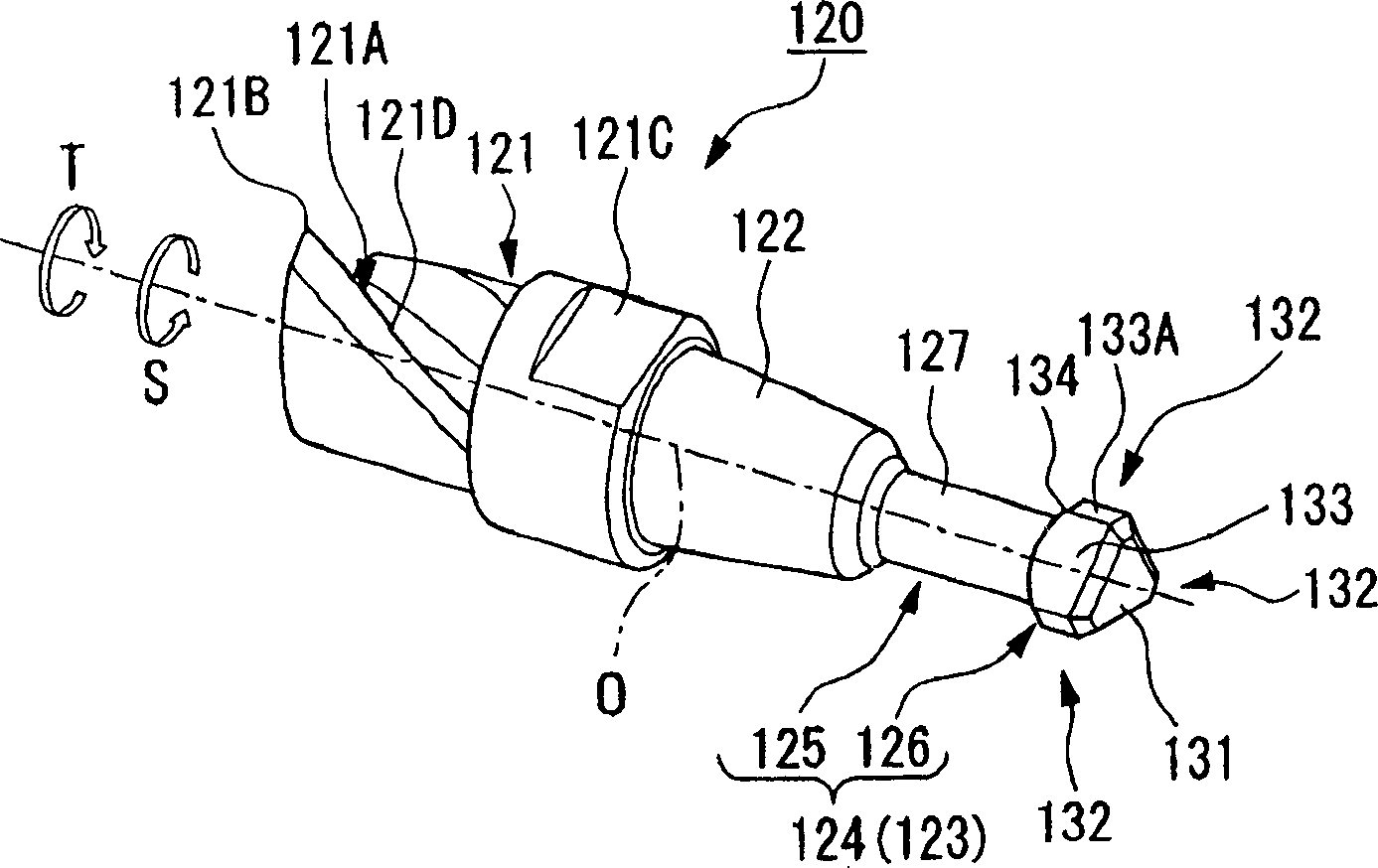

[0099] The cutter head replaceable cutting tool 100 provided by this first embodiment is as figure 1 and figure 2 As shown, a tool body 110 that can rotate around the axis O, a cutter head 120 that is detachably mounted and fixed on the tool body 110 , and a pull-in tool for installing the cutter head 120 on the tool body 110 The bolt portion 140 of the component constitutes.

[0100] The tool body 110 is, for example, made of steel and has a substantially cylindrical shape centered on the axis O, and has a mounting hole 112 centered on the axis O from the front end surface 111 toward the rear end side.

[0101] The mounting hole 112 is composed of a conical hole 113, an accommodating hole 114 and a female thread portion 115; wherein, the inner diameter of the conical hole 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com