Motor unit

A technology for electric motors and mounting plates, which is applied in the direction of electromechanical devices, electric components, electrical components, etc., and can solve problems such as burrs or flashes on the shear surface and reduced driving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

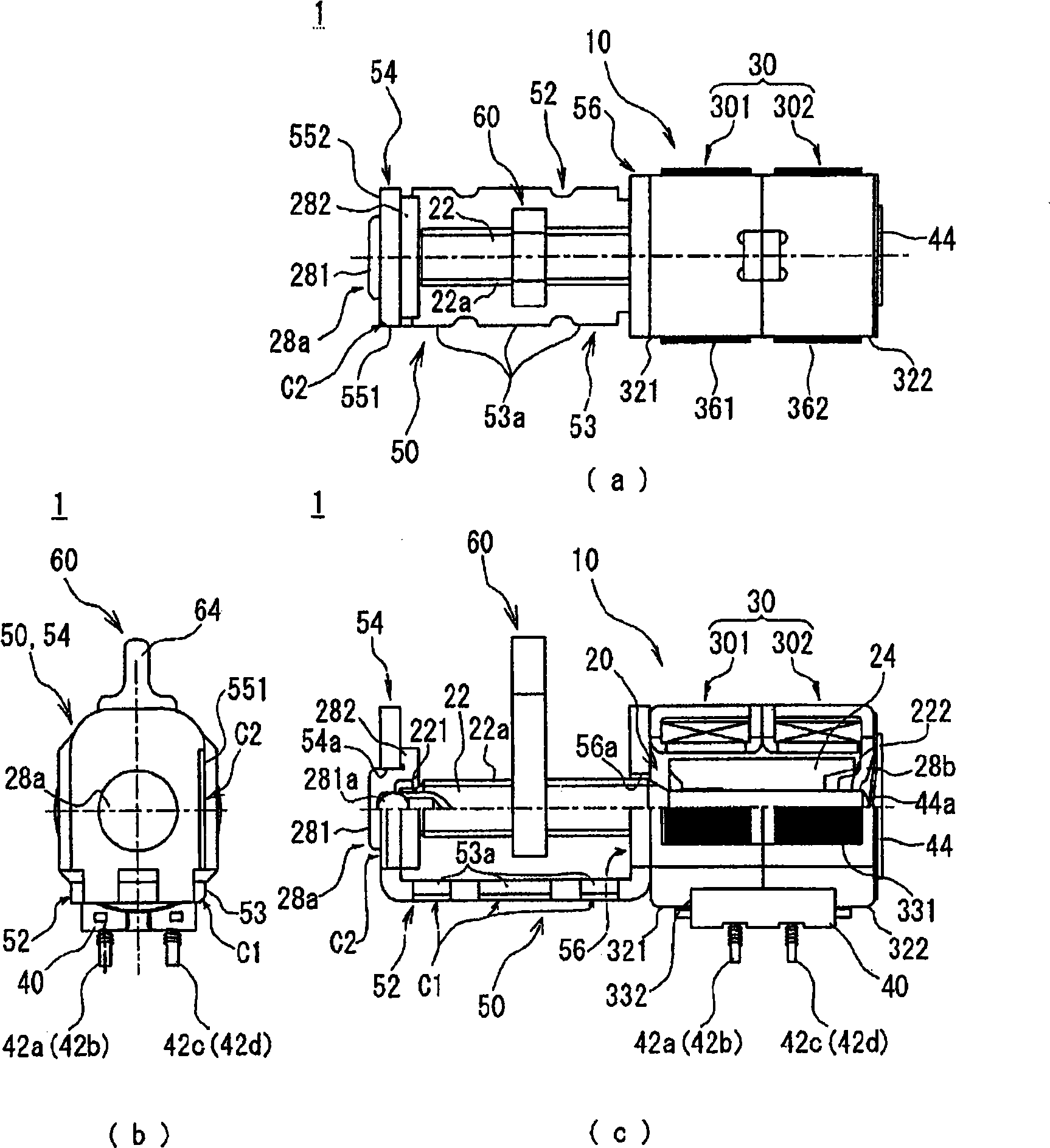

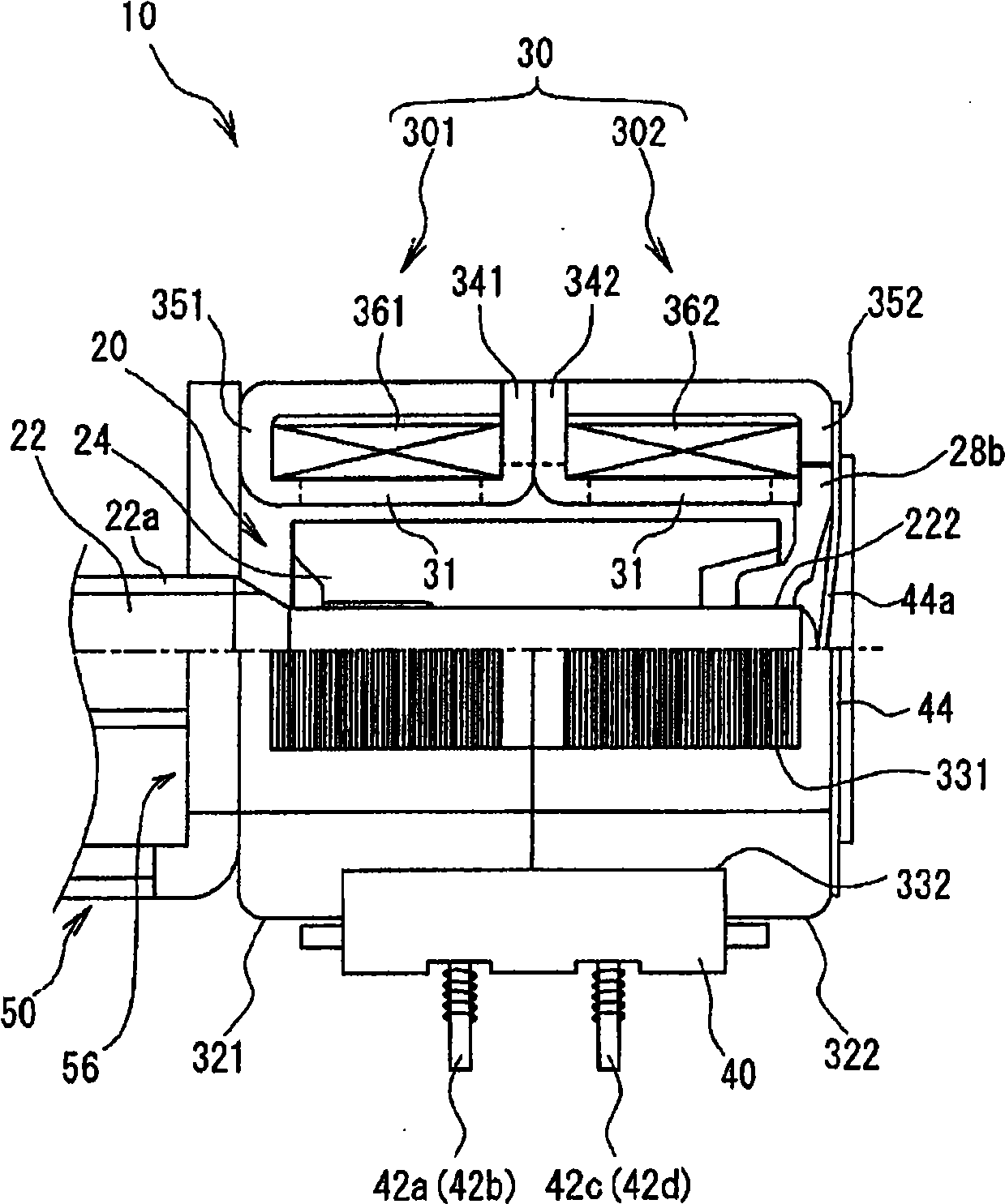

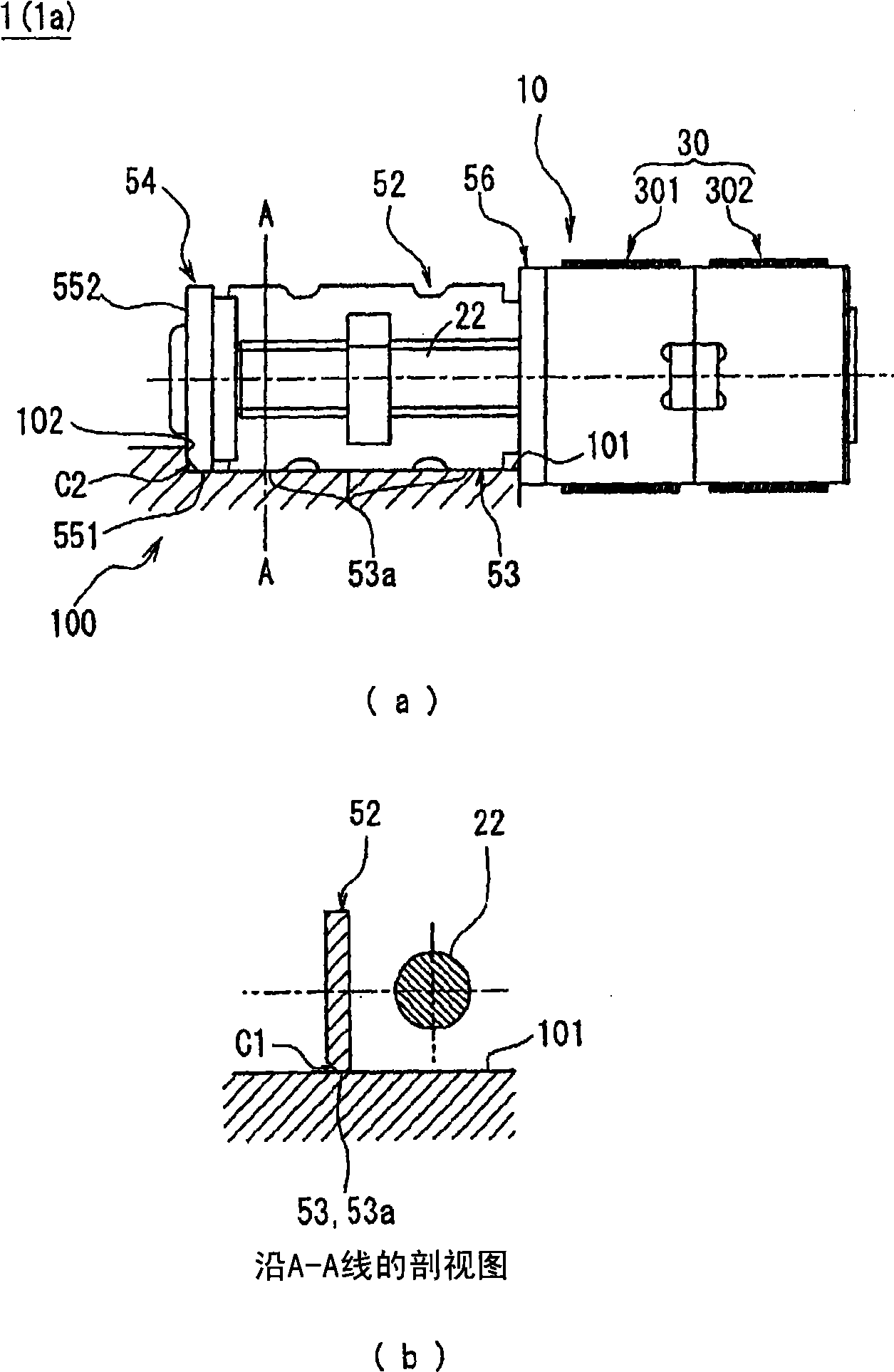

[0061] image 3 (a) is a figure which shows the state which mounted|worn the motor device 1a of 1st Embodiment to a motor drive facility. image 3 (b) is along image 3 (a) A cross-sectional view taken along line A-A. Such as image 3 As shown, the motor unit 1a is fixed in a state where one side surface 53 of the bottom plate portion 52 is in contact with the mounting surface 101 of the motor mounting portion 100 of the motor drive device. That is, the one side surface 53 of the bottom plate part 52 becomes a contact part which contacts a motor drive device.

[0062] Here, in the present embodiment, on the one side surface 53 of the bottom plate portion 52, as described above, the chamfering processing C1 is performed on the protruding portion 53a at three locations as the contact portion with the motor drive device. Burrs and burrs generated on the protruding portion 53a by press working (cutting work) are removed. Therefore, even if the motor unit 1a is laid on the mou...

no. 2 approach

[0069] exist image 3 In the first embodiment shown, the one side surface 53 of the bottom plate portion 52 and the one side surface 551 of the rotating shaft support portion 54 are used as abutting portions for abutting against the motor drive device, but they may also be used as Figure 4 The motor device 1b is constructed as shown in (a), except for the one side surface 53 of the bottom plate portion 52, the one side surface 57 of the stator support portion 56 ( Figure 4 The lower side surface in (a) also serves as an abutment portion that abuts against the motor drive device. When constituted in this way, like the first embodiment, the abutting portion of the motor unit 1b that abuts against the mounting surface 101 of the motor mounting portion 100 of the motor drive equipment is in an “L” shape, so that the motor unit 1b can be mounted in an installed state. become stable. In this case, in order to prevent the motor unit 1b from tilting,

[0070] It is necessary to p...

no. 3 approach

[0072] In the first embodiment and the second embodiment, the one side surface 53 of the bottom plate portion 52 and the one side surface 551 of the rotating shaft support portion 54, or the one side surface 53 of the bottom plate portion 52 and the one side surface 57 of the stator support portion are used as the motor device. The abutment part of the abutment, the abutment part is "L" shaped, but it can also be as Figure 4 The motor unit 1c is configured as shown in (b), and one side surface 53, 551, 57 of the bottom plate portion 52, the rotating shaft support portion 54, and the stator support portion 56 is used as an abutting portion for the motor drive device. With this structure, the abutting portion has a U-shape with respect to the mounting surface 101 of the motor mounting portion 100 of the motor drive device, so that the mounting state of the motor unit 1c can be made more stable. In addition, it is necessary to similarly perform cutting or grinding on the respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com