Biological active bone tissue inducing regeneration film and preparation method

A technology of biological activity and bioactive factors, applied in the field of medical materials and their preparation, can solve the problems of no tissue induction, achieve huge social and economic benefits, be easy to control, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

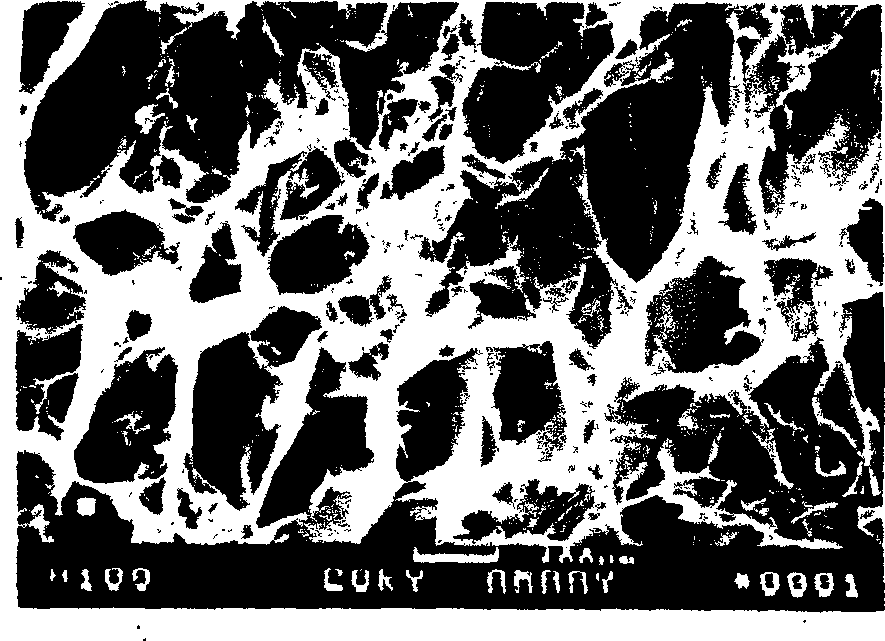

Image

Examples

Embodiment 1

[0024] Weigh 2 grams of polylactic acid with a viscosity of 3.51 with a balance, add it to 40ml of ethyl acetate, and swell at room temperature for 12 hours, stir and dissolve for 1 hour, and after defoaming for 1 hour, pour it into a 10×10cm flat mold. What this embodiment chooses is flat flow casting film on flat glass mold, then put it into a semi-closed container to slowly volatilize ethyl acetate for 1 day, then open and volatilize for 2 days, then vacuum dry at 70°C for 8 hours to remove residual of ethyl acetate.

[0025] Under the condition that the prepared polylactic acid membrane is separated from the surrounding membrane without demolding, use a probe to scratch and roughen the surface to form staggered scratches with a depth of 1 to 10 microns, and then place the cow 0.5 g of collagen was dissolved in 0.01M acetic acid and made into a 3% collagen solution, which was evenly spread on the scratched membrane surface, and then evaporated and dried naturally at room te...

Embodiment 2

[0029] Use a balance to weigh 3 grams of polylactic acid with a viscosity of 3.32, add it to 50ml of ethyl acetate, and swell at room temperature for 15 hours, stir and dissolve for 2 hours, and after defoaming for 1 hour, pour it into a 14×14cm flat mold. What this embodiment chooses is flat flow casting film on flat glass mold, then put into semi-closed container and volatilize ethyl acetate slowly for 2 days, then open and volatilize for 1 day, then vacuum dry at 60°C for 6 hours to remove residual of ethyl acetate.

[0030] Under the condition that the prepared polylactic acid membrane is separated from the surrounding membrane without demoulding, use a probe to scratch and roughen the surface to form staggered scratches with a depth of 1 to 10 microns, and then place the pig 1.0 g of collagen was dissolved in 0.01M acetic acid and made into a 1% collagen solution, which was evenly spread on the scratched membrane surface, and then evaporated and dried naturally at room te...

Embodiment 3

[0034] Use a balance to weigh 3 grams of polylactic acid with a viscosity of 3.78, add it to 100ml of ethyl acetate, and swell at room temperature for 18 hours, stir and dissolve for 2 hours, and after defoaming for 2 hours, pour it into a 14×14cm flat mold. What this embodiment chooses is flat flow casting film on flat glass mold, then put into semi-closed container and volatilize ethyl acetate slowly for 2 days, then open and volatilize for 2 days, then vacuum dry at 80°C for 10 hours to remove residual of ethyl acetate.

[0035] Under the condition that the prepared polylactic acid membrane is separated from the surrounding membrane without demolding, use a probe to scratch and roughen the surface to form staggered scratches with a depth of 1 to 10 microns, and then place the cow 1.0 g of collagen was dissolved in 0.01M acetic acid and made into a 2% collagen solution, evenly spread on the scratched membrane surface, and allowed to evaporate and dry naturally at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com