A method for individualised marking of circuit boards

A technology for distinguishing marks and circuit boards, applied in circuit inspection/identification, removal of conductive materials by chemical/electrolytic methods, circuits, etc., can solve problems such as unsuitable exposure technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

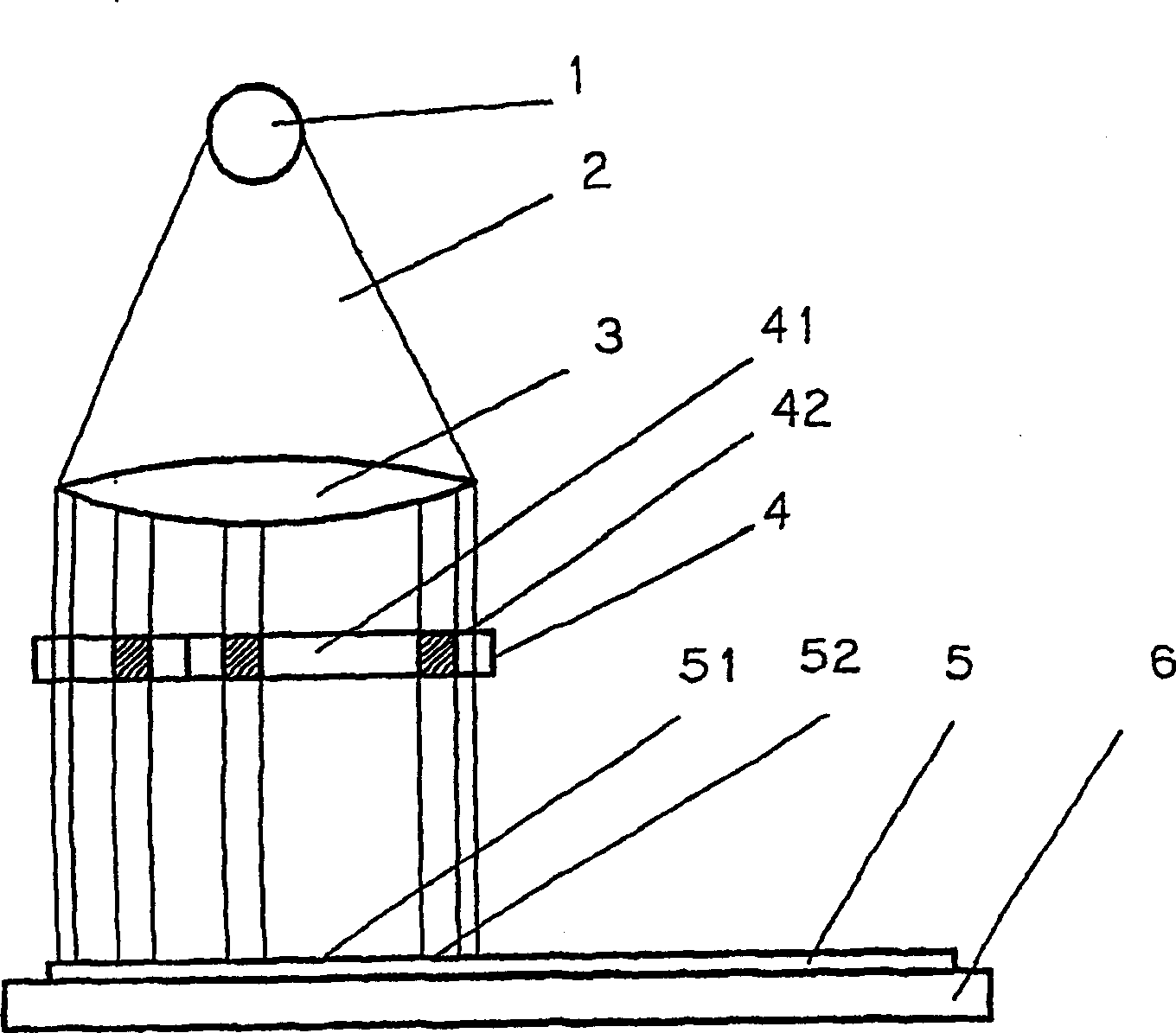

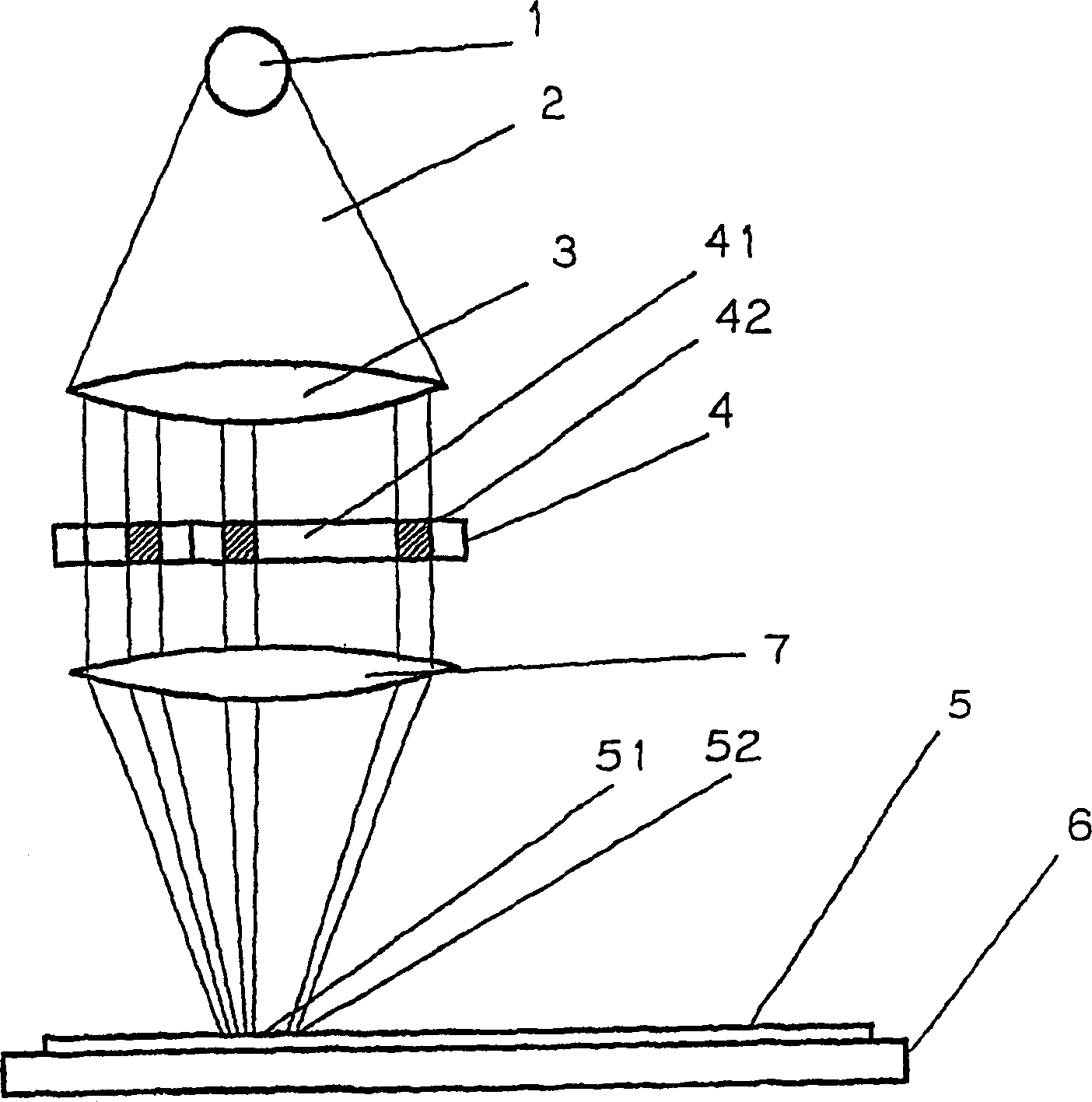

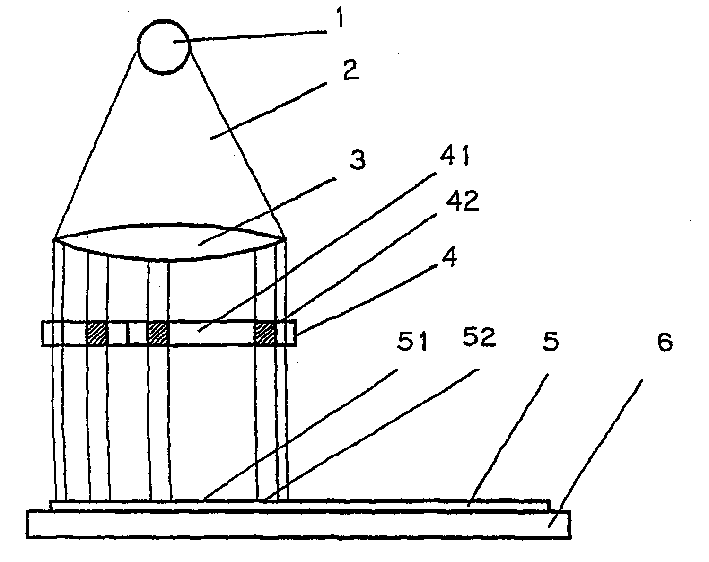

[0037] In the figures, the same reference numerals denote mutually corresponding elements. exist figure 1 In, reference numeral 1 denotes a light source, and reference numeral 2 denotes its light beam, which is directed to a photosensitive surface portion 5 of a circuit board 6 to be marked. An optical device 3 and a device 4 with adjustable transparency are arranged in the light beam 2 of the light source 1 . The device 4 comprises a region 41 which is in the direction of propagation of the light and which allows the passage of light, and a region 42 which does not allow the passage of light or whose transparency is substantially lower than that of the region 41 .

[0038] The shape and position of the areas 41 and 42 are selected so that by means of them a pattern corresponding to the desired marking can be formed on the photosensitive surface 5 of the circuit board 6 . The figures do not show the means for adjusting the shape and / or position of the regions 41 and 42 . In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com