Tiltmeter

A technology of tilt detector and fixed contact, applied in the direction of measuring tilt, instruments, measuring devices, etc., can solve the problems of low detection accuracy and unstable contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

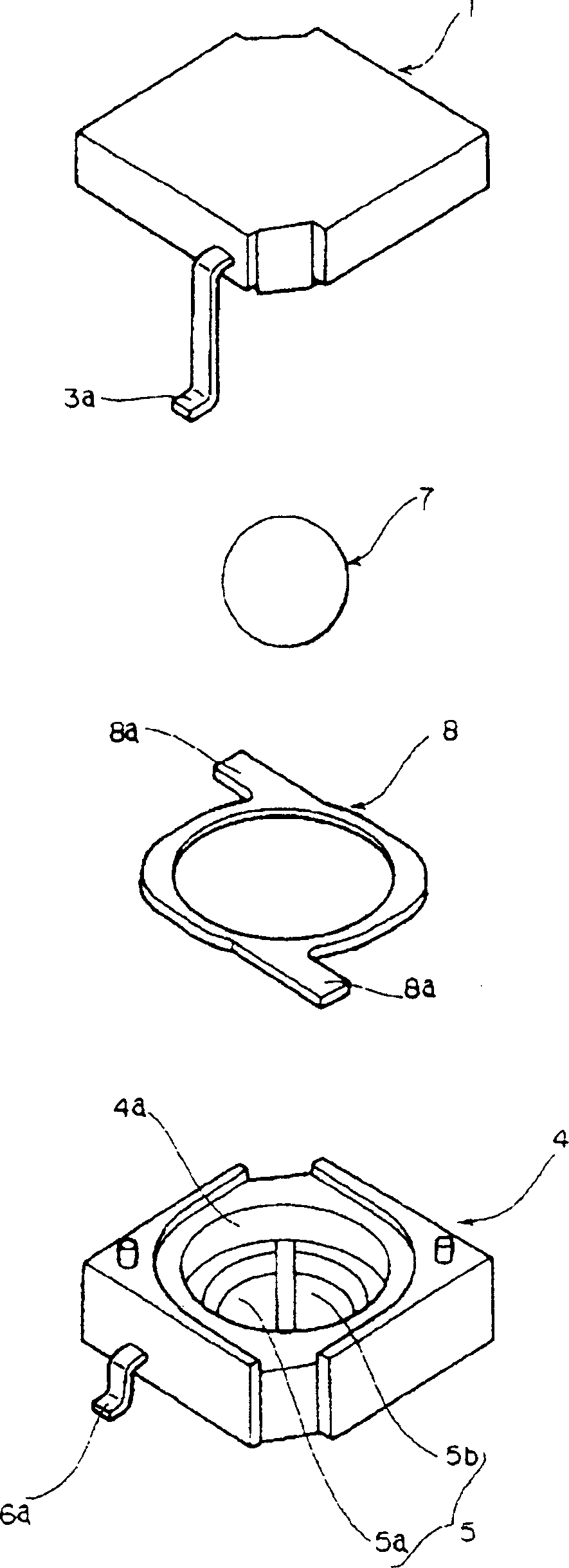

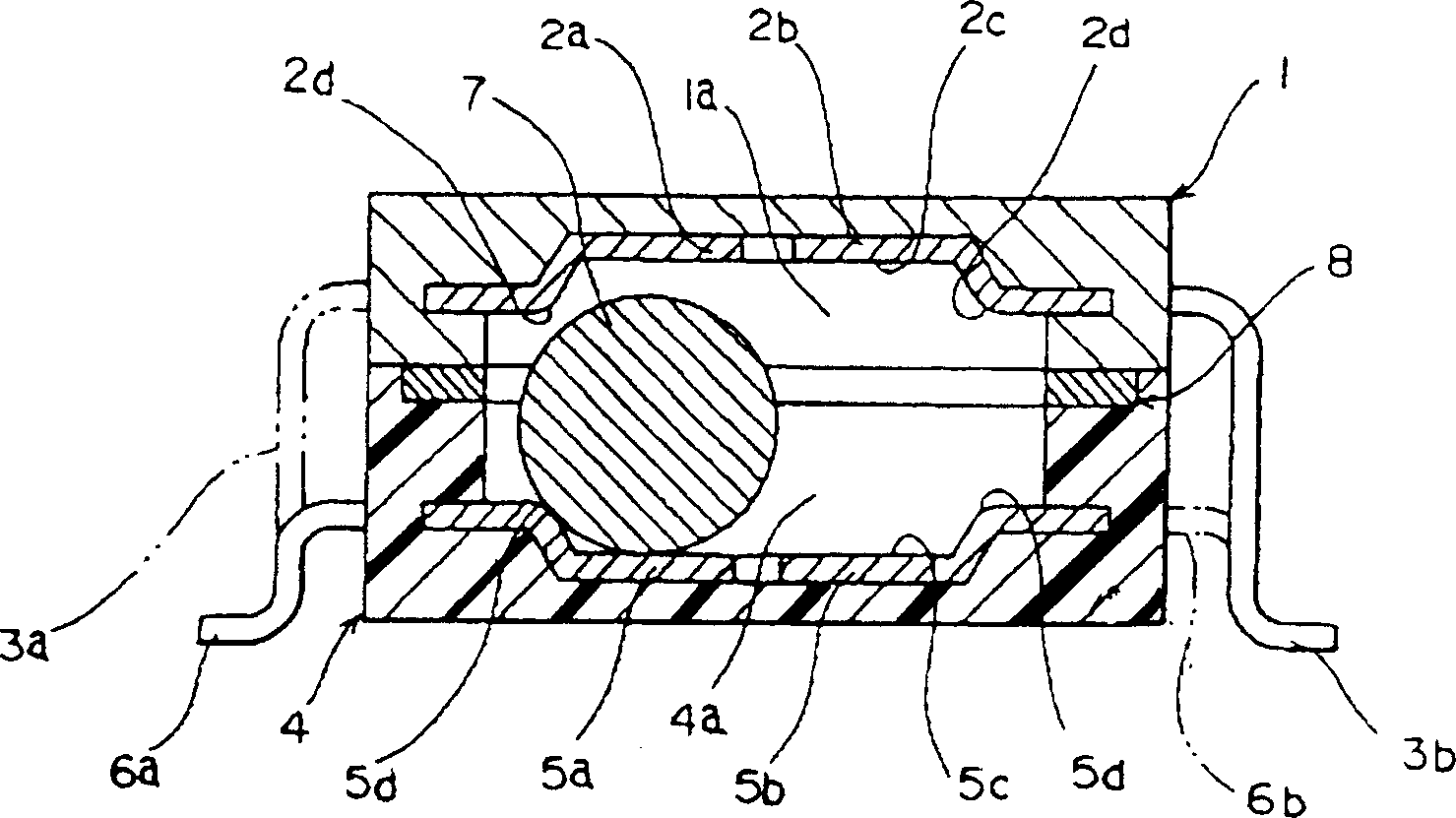

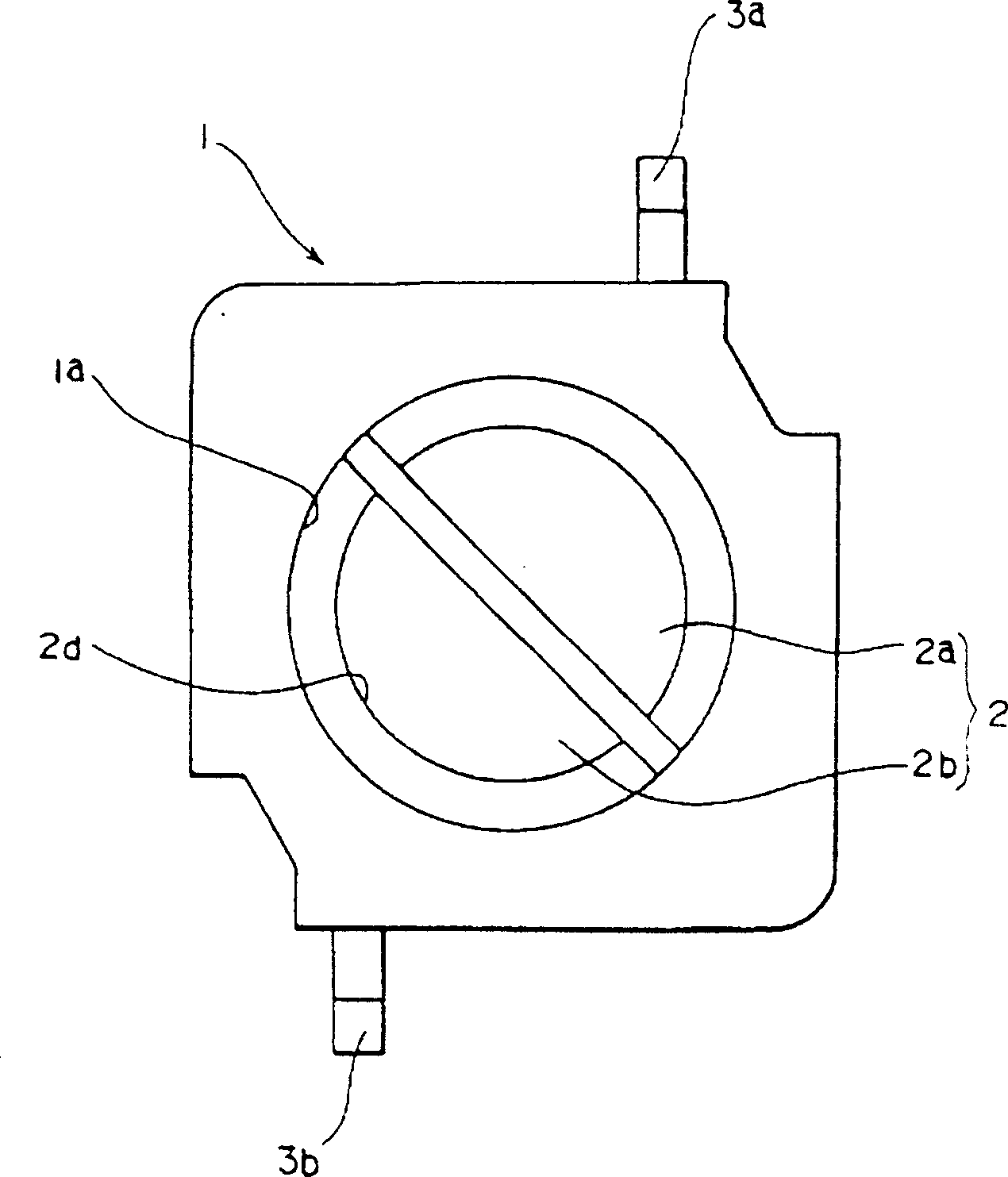

[0023] the following Figure 1 to Figure 7 Embodiments of the present invention are shown. figure 1 is the exploded oblique view of the tilt detector, figure 2 is a longitudinal section view, image 3 is the bottom view of the first case, Figure 4 is the plan view of the second case, Figure 5 It is an explanatory diagram showing the operating state of the movable contact when tilted to the left, Figure 6 It is an explanatory diagram showing the operating state of the movable contact when tilting to the right, Figure 7 It is a longitudinal sectional view showing another embodiment.

[0024] In the figure, the first housing 1 is made of an insulating material such as synthetic resin and is formed into a box shape with an open bottom. In the opening of the first case 1, a bottomed and circular first housing portion 1a is formed, and on the inner bottom surface of the first housing portion 1a, a first housing made of a conductive metal plate is provided almost on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com