Method for mfg. intake manifold for electric injection engine

A technology of intake manifold and processing method, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of large volume, high cost per piece, and large equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

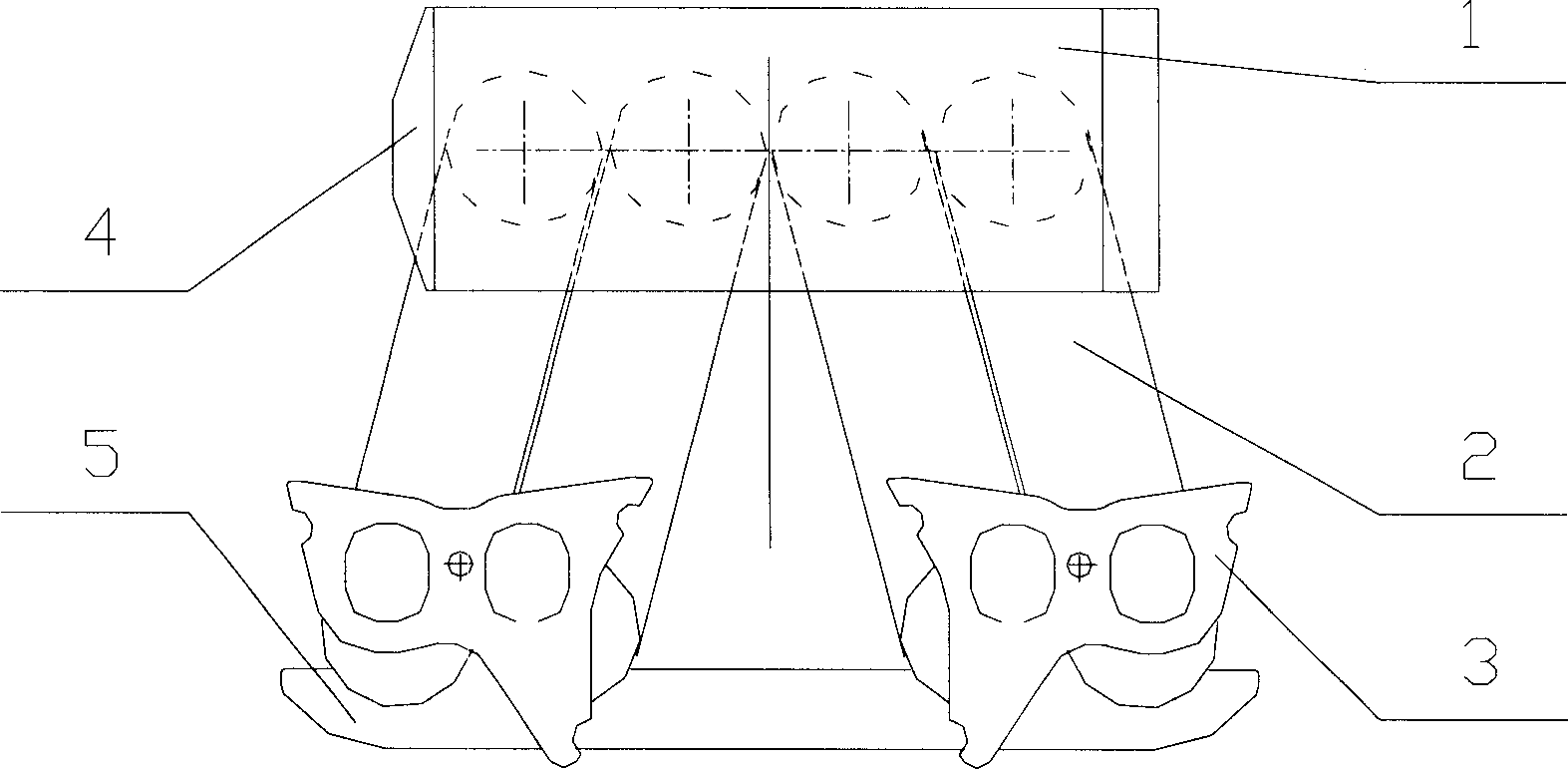

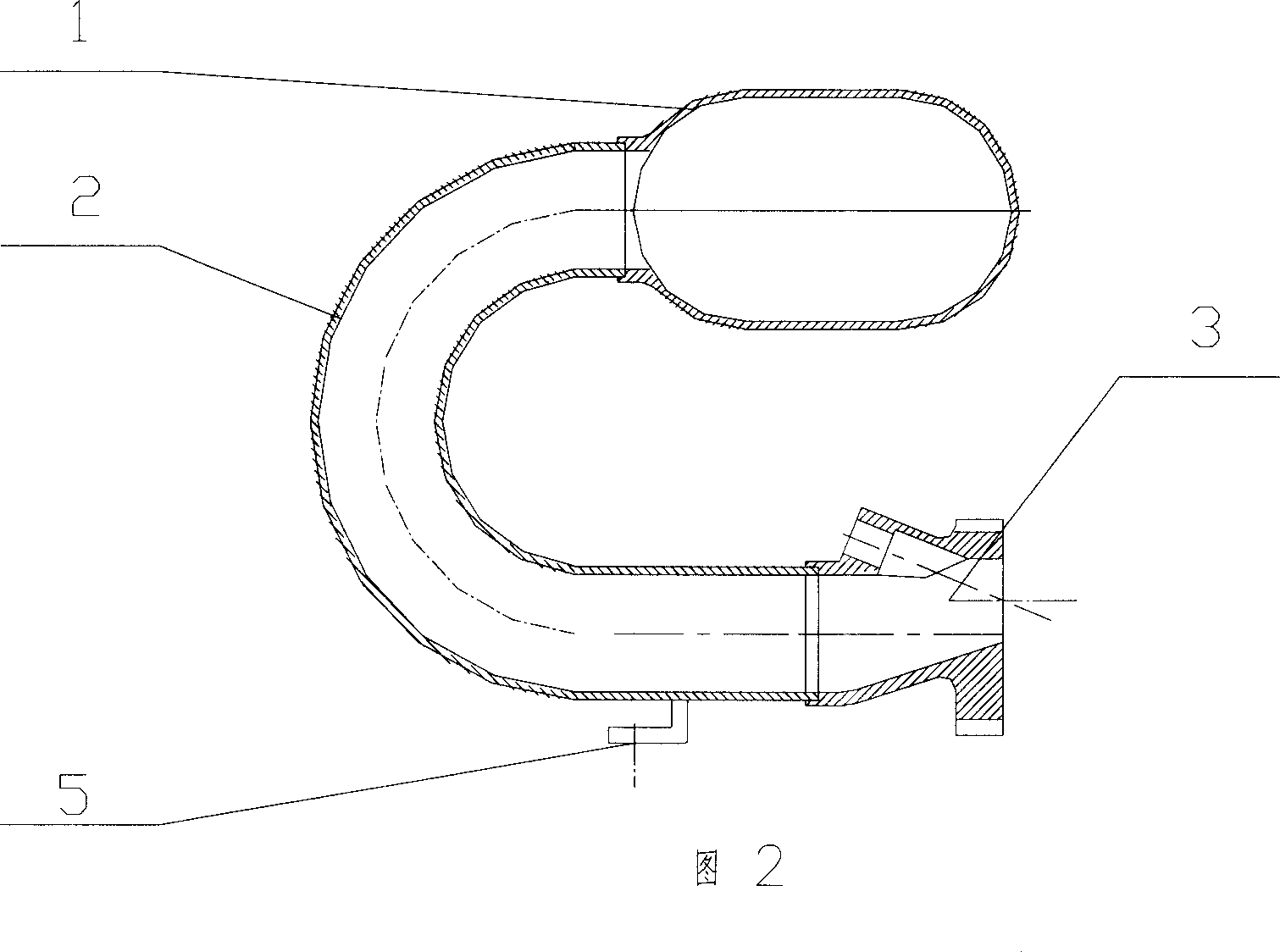

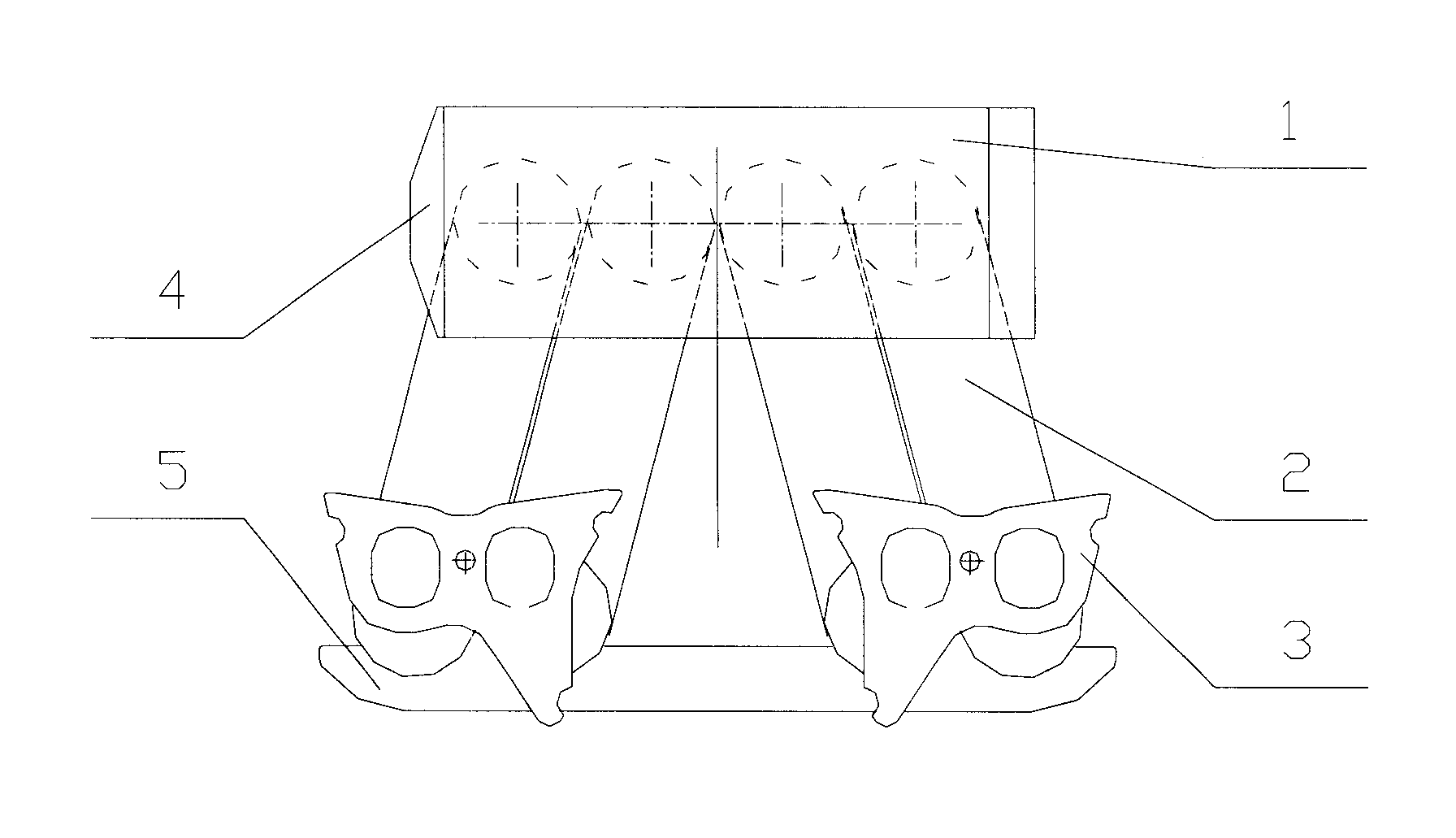

[0013] Depend on figure 1 --- As shown in Fig. 2, the present invention is

[0014] a. After the intake manifold is cut and blanked, it is bent and formed by a CNC pipe bender with a bending angle of 180 degrees.

[0015] b. After the metal sheet is blanked, it is extruded into a cylindrical shape with a mold, then stretched and formed, and processed by a CNC machine tool according to the designed size to cut the blank and process it into a voltage stabilizing box.

[0016] c. The voltage stabilizing box plug is processed by precision die-casting, and then the voltage stabilizing box plug and the voltage stabilizing box body are bonded, and then the periphery of the junction between the voltage stabilizing box body and the voltage stabilizing box plug is riveted.

[0017] d. Sub-arc welding is performed between the intake manifold seat formed by precision die-casting and the inlet end of the intake manifold.

[0018] e. Weld the intake manifold frame on the outer wall of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com