Polisher

A technology of polishing machine and frame, which is applied in surface polishing machine tools, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc., which can solve the problems of improving and stabilizing product quality, and separating the main machine from the small material barrel. Problems such as unreasonable design, not suitable for high-volume and high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

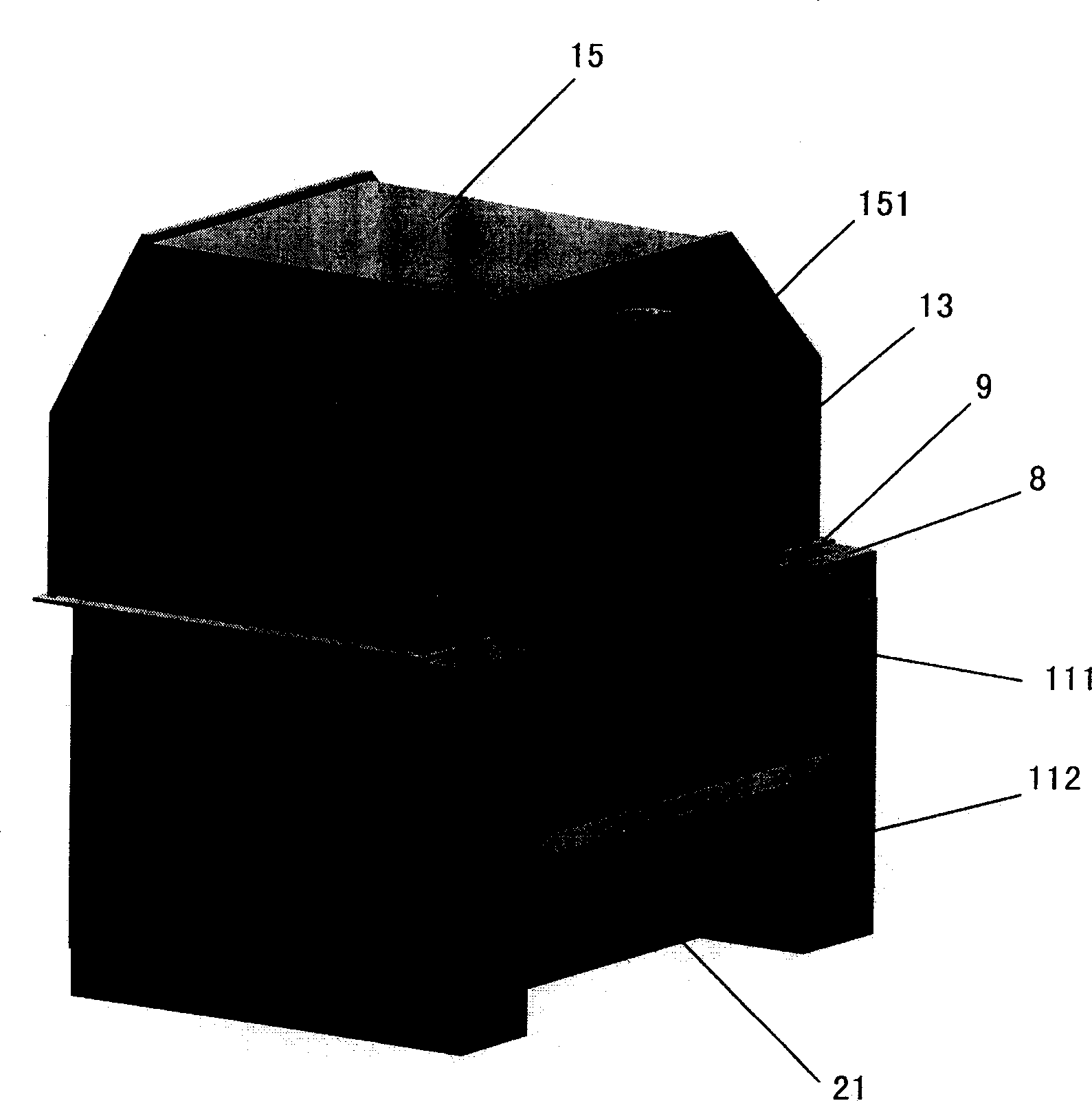

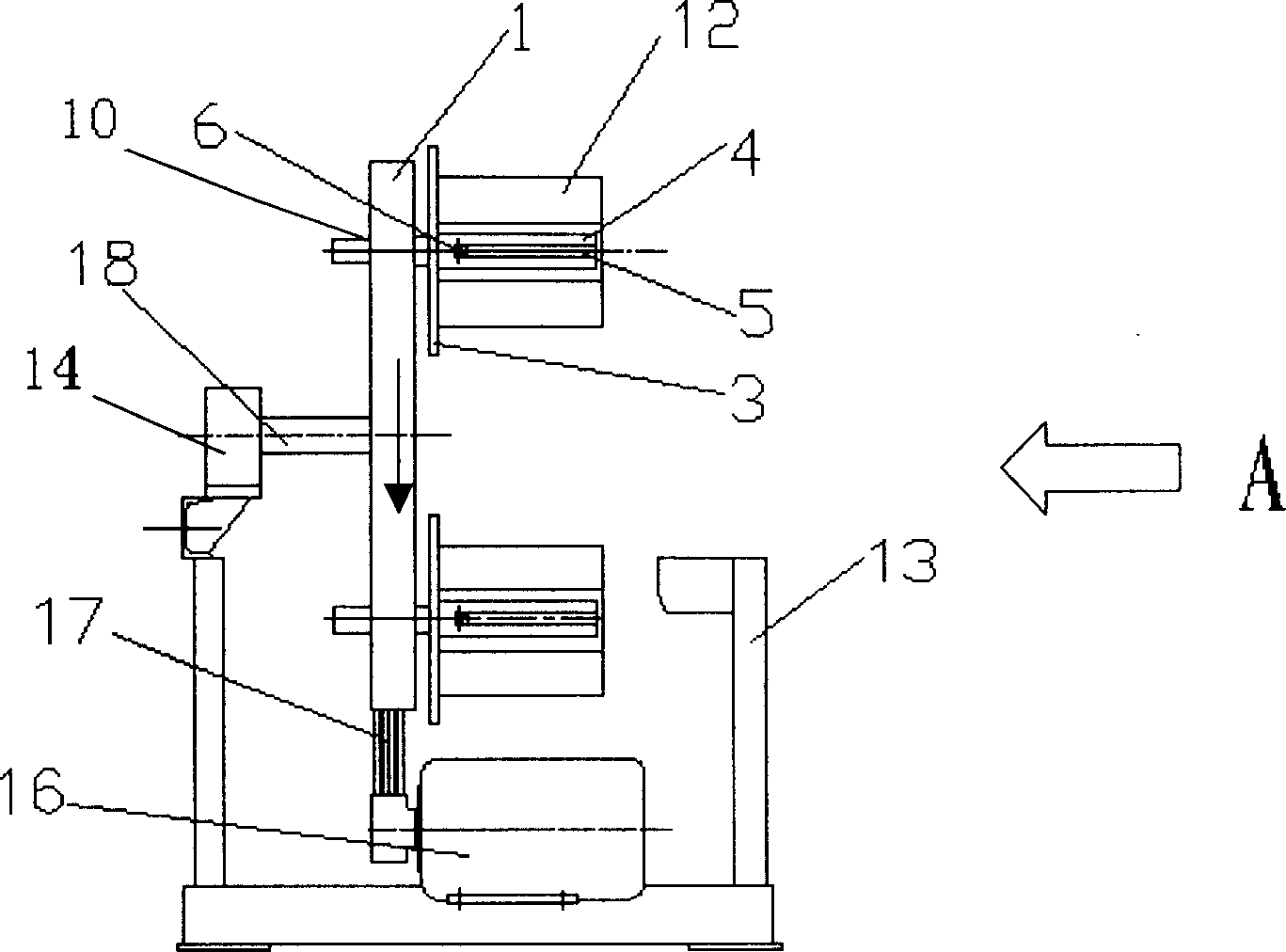

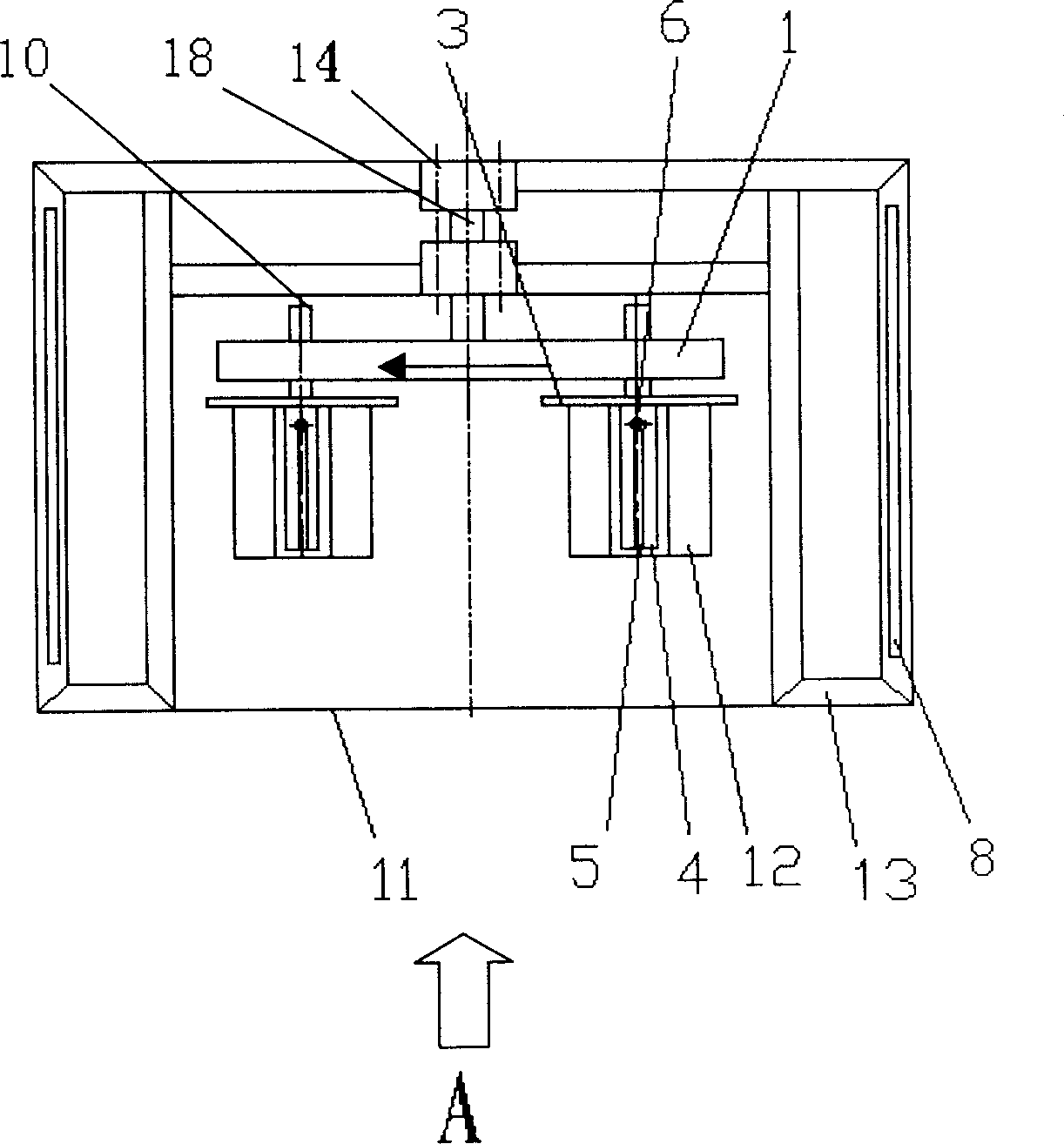

[0015] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

[0016] On the basis of many years of development and production of horizontal planetary polishing machine, that is, traditional polishing machine, the present invention has developed the polishing machine of the present invention, which is named planetary end disc polishing machine, in view of the problems existing in existing products through in-depth research of enterprises. machine. Polishing machine of the present invention (see figure 1 , 2 , 3) including parts and structures such as original frame 13, baffle plate 11, cover 15, planetary gear train 1, small bucket 2, but still adopt the planetary gear train transmission principle, to keep the machine movement aspect high efficiency features. It is characterized in that the planetary gear train 1 adopts a cantilever beam structure and is installed on the frame 13 by using the support 14, and the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com