Improved method for integrating touch screen closely

A touch screen, flexible technology, applied in the direction of digital output to display devices, layered products, etc., can solve the problems of low pass rate, growth of manpower demand, low production efficiency, etc., to improve the pass rate and production efficiency, and achieve significant technological progress. and creativity, the effect of improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

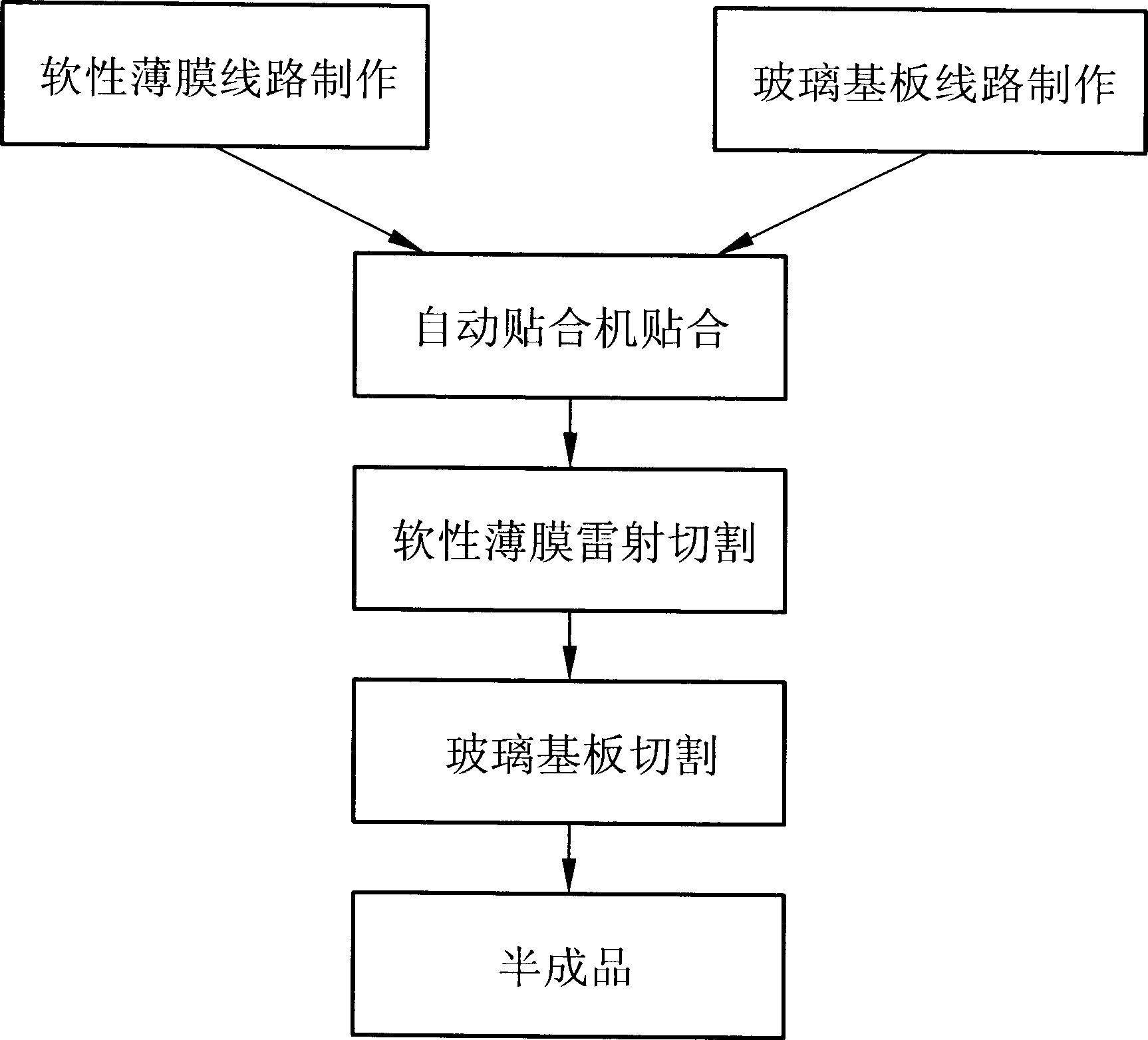

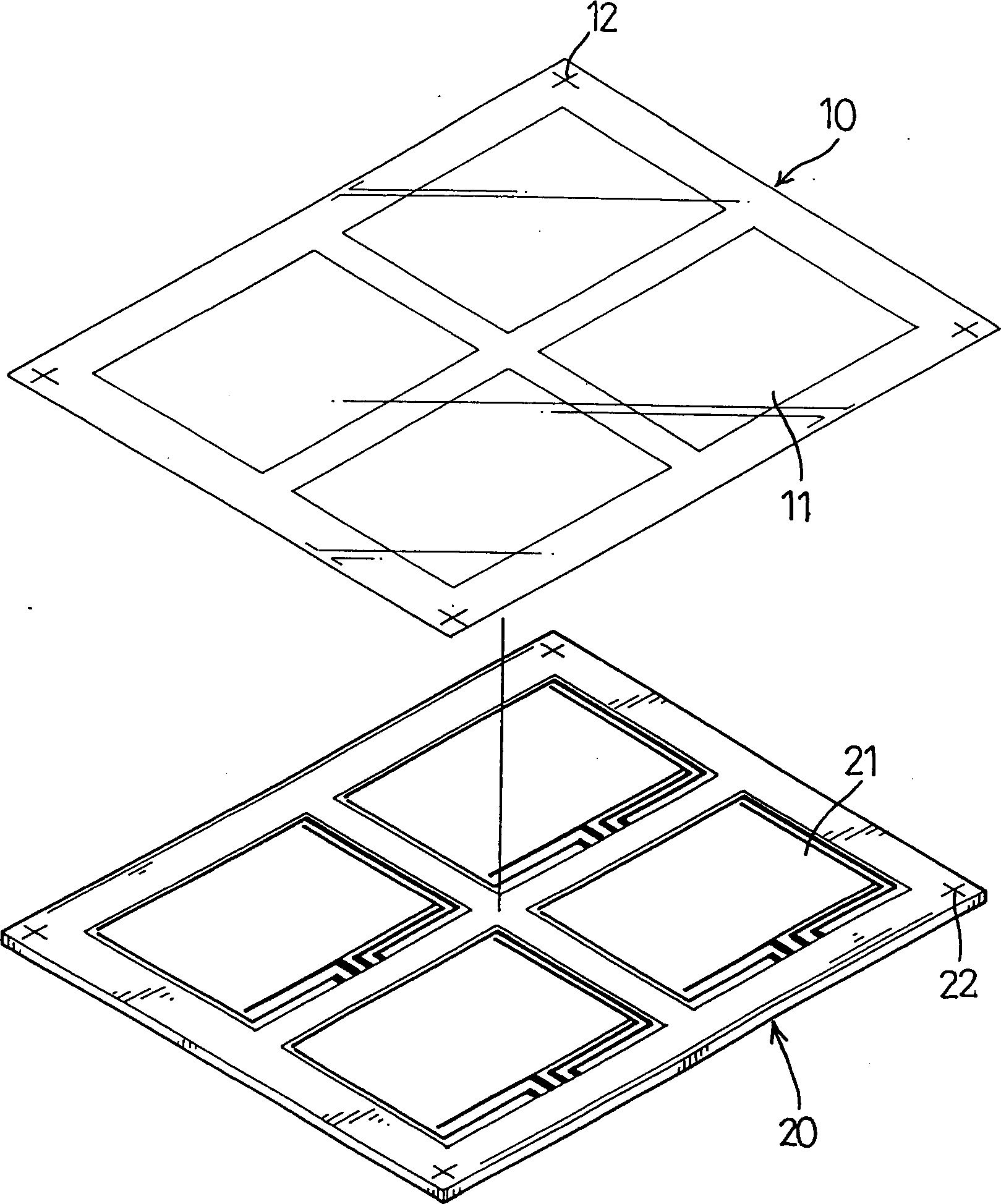

[0025] See attached figure 1 And attached figure 2 As shown, the content of the present invention is mainly that a flexible film 10 and a glass substrate 20 constituting the touch screen are firstly planned out line patterns according to the required size, and the line patterns are arranged in order and arranged in corresponding positions. relationship, and carry out the etching of the circuit and the fabrication of the indium tin oxide conductive layer, and form several thin film circuit devices 11 and substrate circuit devices 21 on the surface of the flexible film 10 facing the glass substrate 20 .

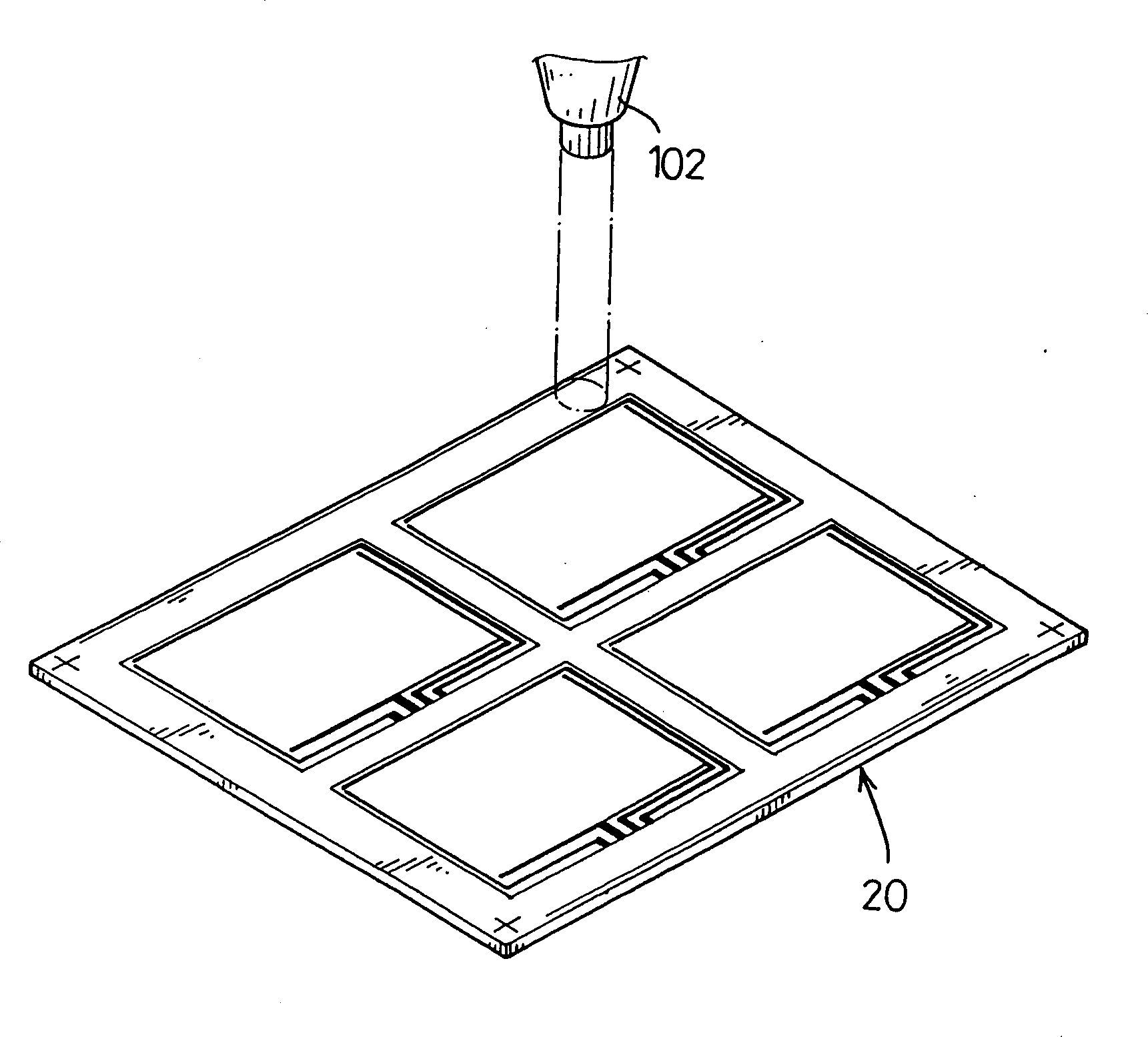

[0026] At the same time, at the four corners of the flexible film 10 and the glass substrate 20, respectively, four opposite film positioning points 12 and substrate positioning points 22 are respectively provided, so that the automatic laminating machine c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com