Potato biscuit and its preparing method

A potato and potato powder technology, which is applied in food preparation, baking, baked food, etc., can solve the problems of dependence on imports, high requirements for potato varieties and quality, and difficulty in making biscuits, so as to achieve good appearance and taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

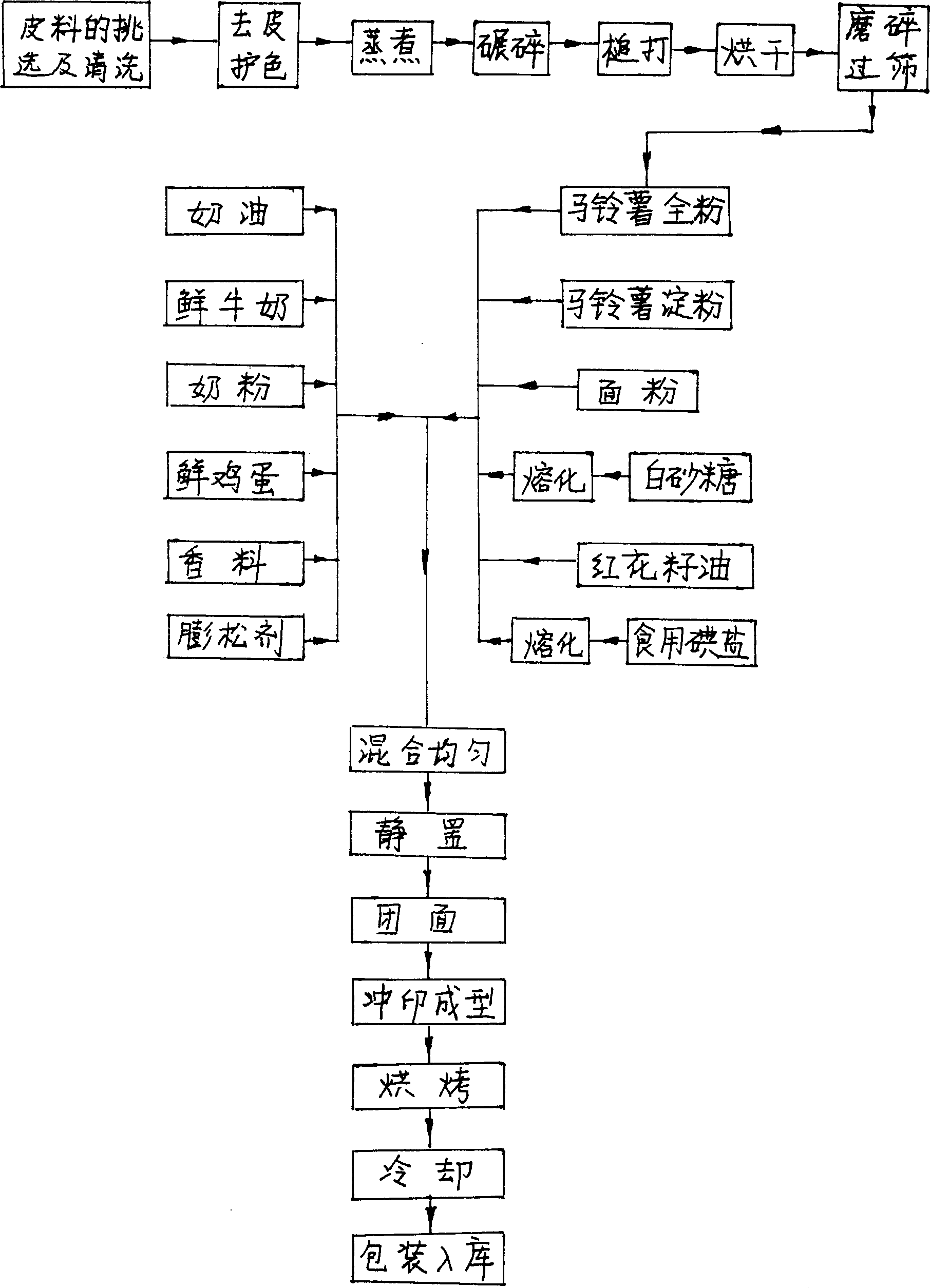

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: a kind of potato biscuit, it is made of 15% potato whole flour, 25% potato starch, 26% flour, 7% white granulated sugar, 10% butter, 7% fresh milk, 3% Milk powder, 5% fresh eggs, 1% safflower oil, 0.2% spices, 0.8% leavening agent. (1) Production of potato flour: select qualified potatoes without rot, deterioration, and no pests and diseases, dig out bud eyes and disabled parts, and put them into a brush-type cleaning machine for cleaning; after cleaning, send them to a friction-type peeling machine to remove After peeling, it is sent to the color protection liquid tank for color protection; after color protection, it is sent to a continuous cooking machine for cooking until it is fully cooked without hard core, and then it is sent to a roller rolling machine for crushing to become muddy; then put Put it into the hammering machine and beat it repeatedly, while turning it continuously, until the raw material is soft, flexible and not sticky; put the mashed ...

Embodiment 2

[0014] Embodiment 2: a kind of potato biscuit, it is made of 35% potato whole powder, 15% potato starch, 16% flour, 5.9% white granulated sugar, 12% cream, 5% fresh milk, 3% Milk powder, 6% fresh eggs, 1% safflower oil, 0.4% spices, 0.6% leavening agent, 0.1% edible iodized salt. Make potato flour according to the method in Example 1, then mix it evenly according to the above ratio and let it stand for 1.5 hours, knead the dough and put it into a printing plate to print and shape, and then bake it in a baking machine at 185°C After cooling for 10 minutes, it can be packaged and put into storage.

Embodiment 3

[0015] Embodiment 3: a kind of potato biscuit, it is made of 35% potato whole powder, 25% potato starch, 6% flour, 7.95% white granulated sugar, 8% cream, 6% fresh milk, 5% Milk powder, 5% fresh eggs, 0.6% safflower oil, 0.2% spices, 1% leavening agent, 0.05% edible iodized salt. Make potato flour according to the method of Example 1, then mix it evenly according to the above ratio and let it stand for 2 hours, knead the dough and put it into a printing plate for printing and molding, and then bake it in a baking machine at 220°C After 6 minutes, it can be packaged and put into storage after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com