House composed of large building blocks between two in-situ cast reinforced concrete columns

A horizontal hole and concrete technology, which is applied to building materials, building components, walls, etc., can solve the problems of unstable filling walls, unsuitable for comprehensive promotion, and high production costs, and achieve the effects of high rigidity, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

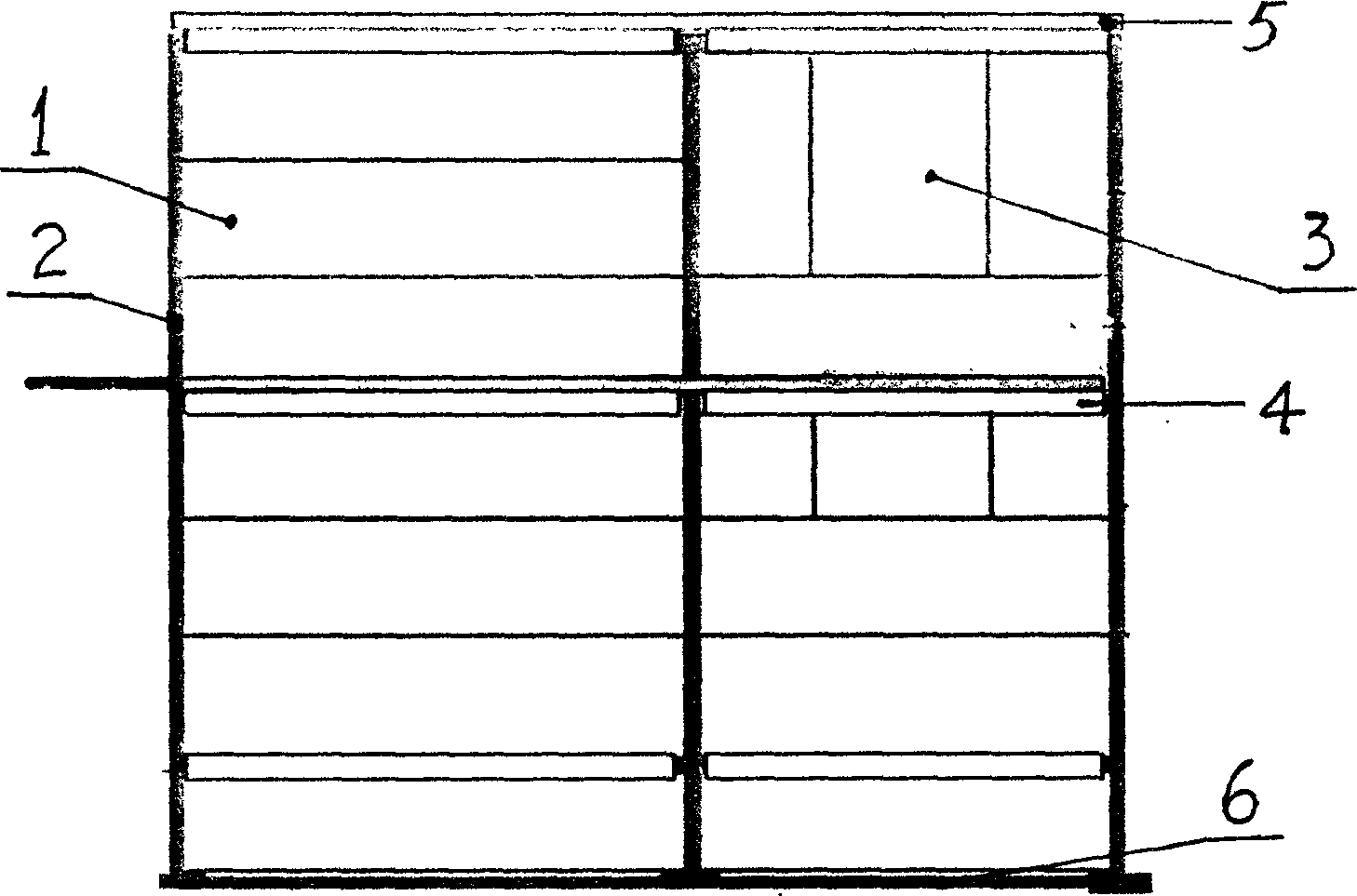

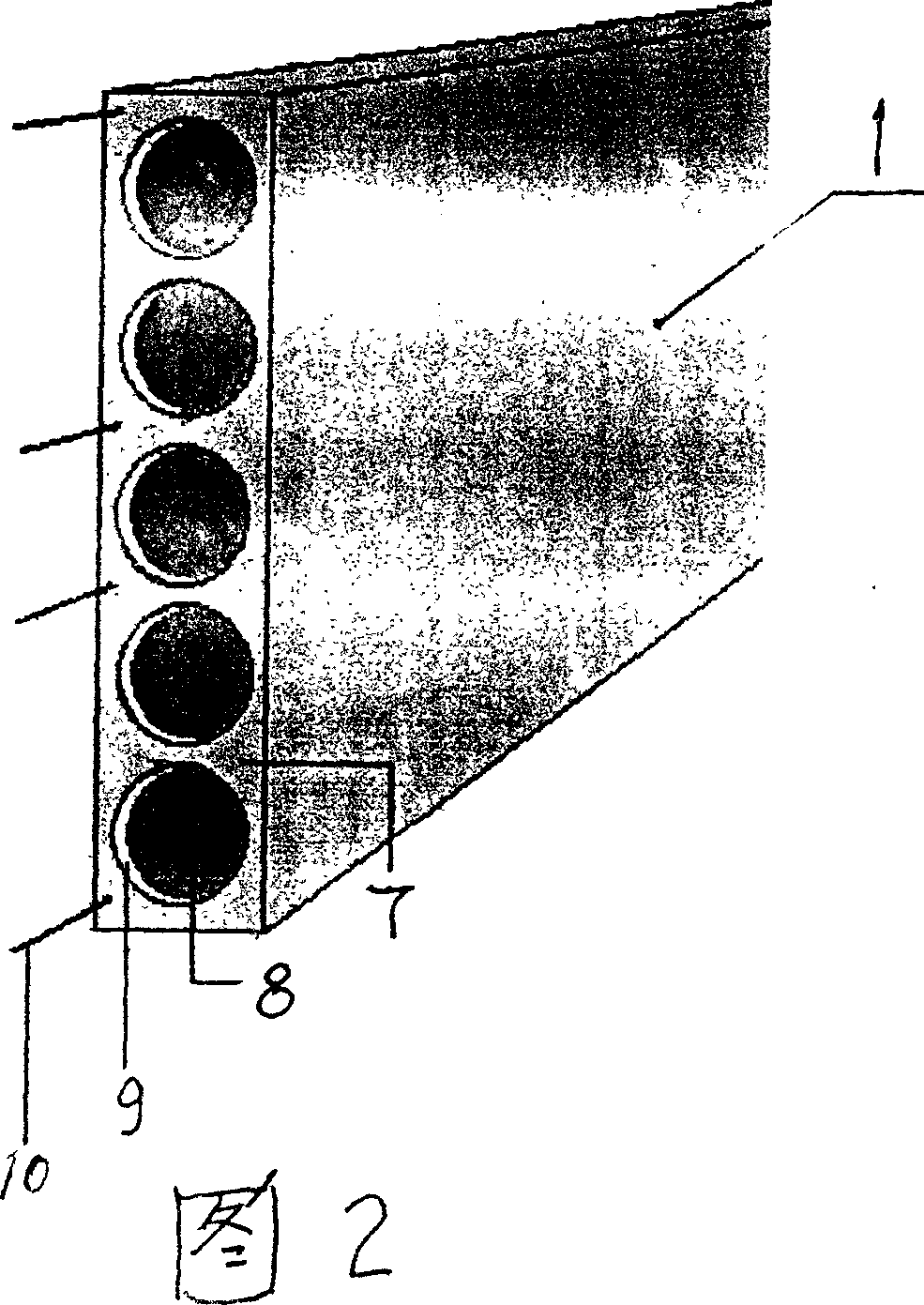

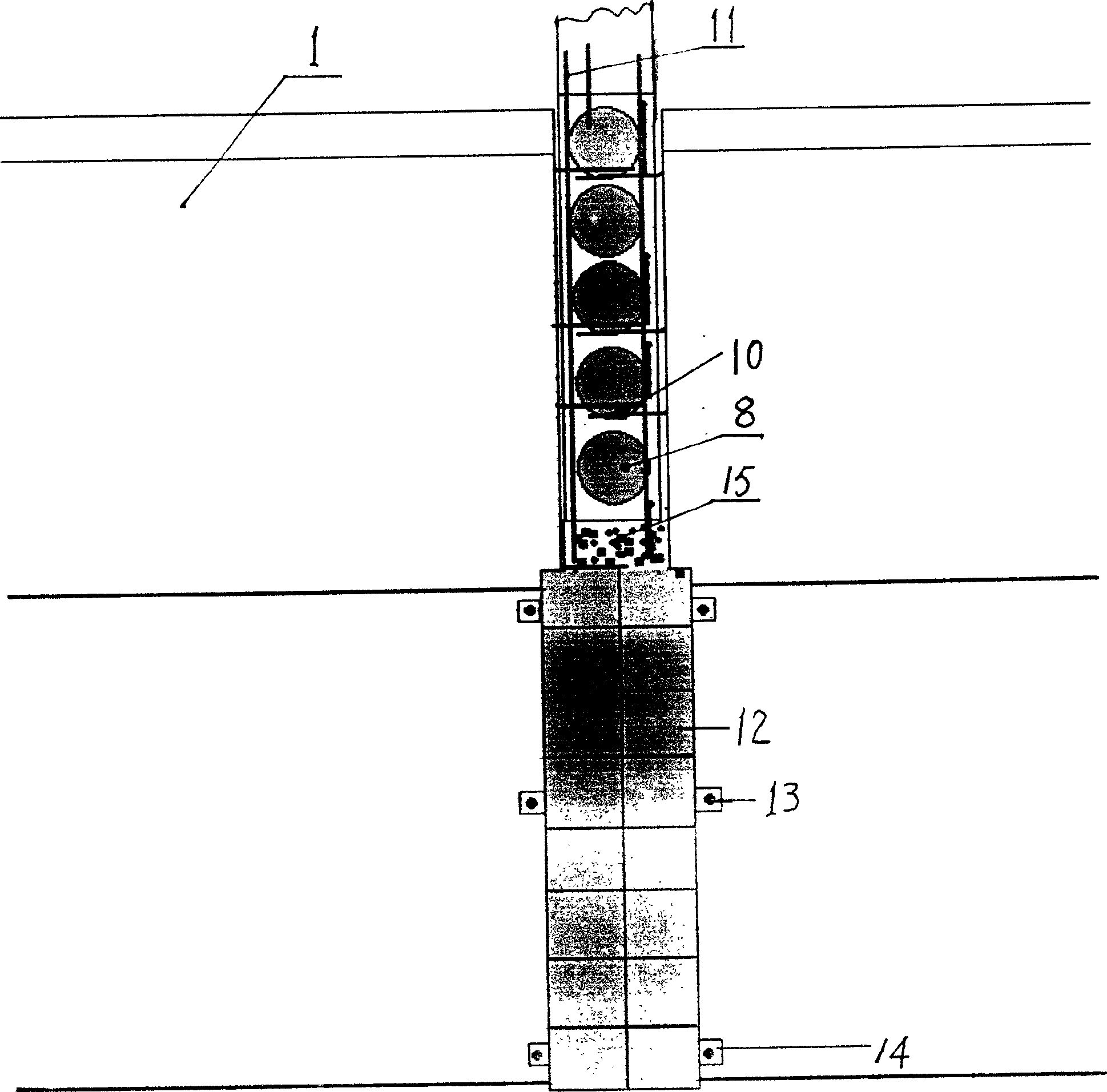

[0013] Such as Figure 1~4 As shown, the present invention is made of large block 1, cast-in-place reinforced concrete column 2, prefabricated ring beam 4, roof slab 5 and concrete cushion 6, and large-scale block 1 is between two cast-in-place reinforced concrete columns 2, and the prefabricated ring The beam 4 is at the upper and lower parts of the large block wall, the roof slab 5 is at the top of the house, and the concrete cushion 6 is at the bottom of the house. It is characterized in that 3 to 5 large blocks 1 are stacked horizontally on one wall of each single room Formed, there are only horizontal seams on one wall of a single room. The large block 1 is rectangular, and it is composed of concrete, several horizontal holes, prestressed steel bars 10, thermal insulation materials 17 in the horizontal holes, and inner hole column plates 8, and the inner hole hanging plates 8 are slightly concave at both ends of the horizontal holes. A section of position that goes in, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com