Method for producing metafluoroethylene by pyrolysis of difluoro-chloroethane

A technology of difluoro-chloroethane and vinylidene fluoride, which is applied in the fields of dehydrohalogenation preparation, organic chemistry, etc., can solve the problems of unstable product quality, high quality requirements for operators, and high requirements for instrument performance, so as to improve continuous operation Cycle time, good quality stability, and low property requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

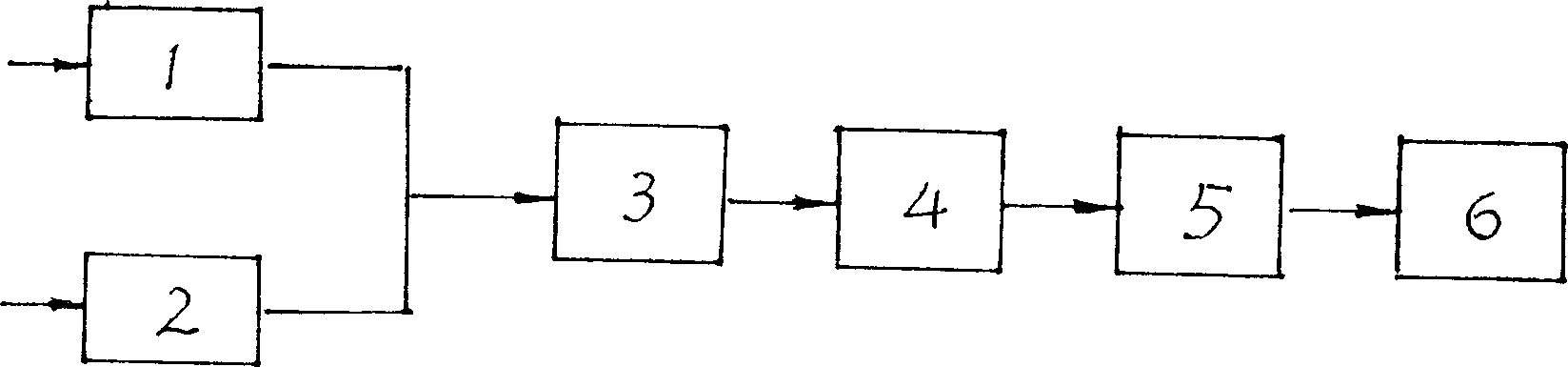

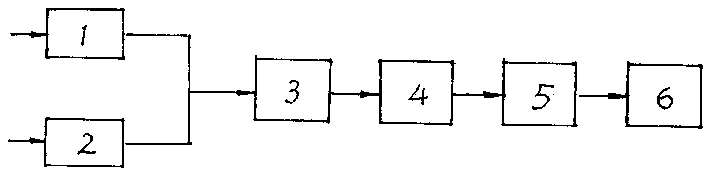

[0025] Reactor 4 in this embodiment adopts an adiabatic tubular reactor with a pipe diameter of Φ22×2. Its technological process is:

[0026] A. Firstly, the superheated steam is heated to 890°C through the hot steam heating device, and the material difluorochloroethane is heated to 250°C through the difluorochloroethane preheating device;

[0027] B. Input the above-mentioned superheated steam into the mixing device 3 at 22500mol / h and preheated difluorochloroethane at 1250mol / h and mix evenly, and the dilution ratio is 18;

[0028] C. Cracking reaction: heat and crack the uniformly mixed superheated steam and materials in the externally heated tubular reactor 4, the reaction residence time is 0.02s, the reactor inlet temperature is 840°C, and the outlet temperature is 780°C.

[0029] D. The above-mentioned cracking reactant is input into the coil cooling device and rapidly cooled to 160°C.

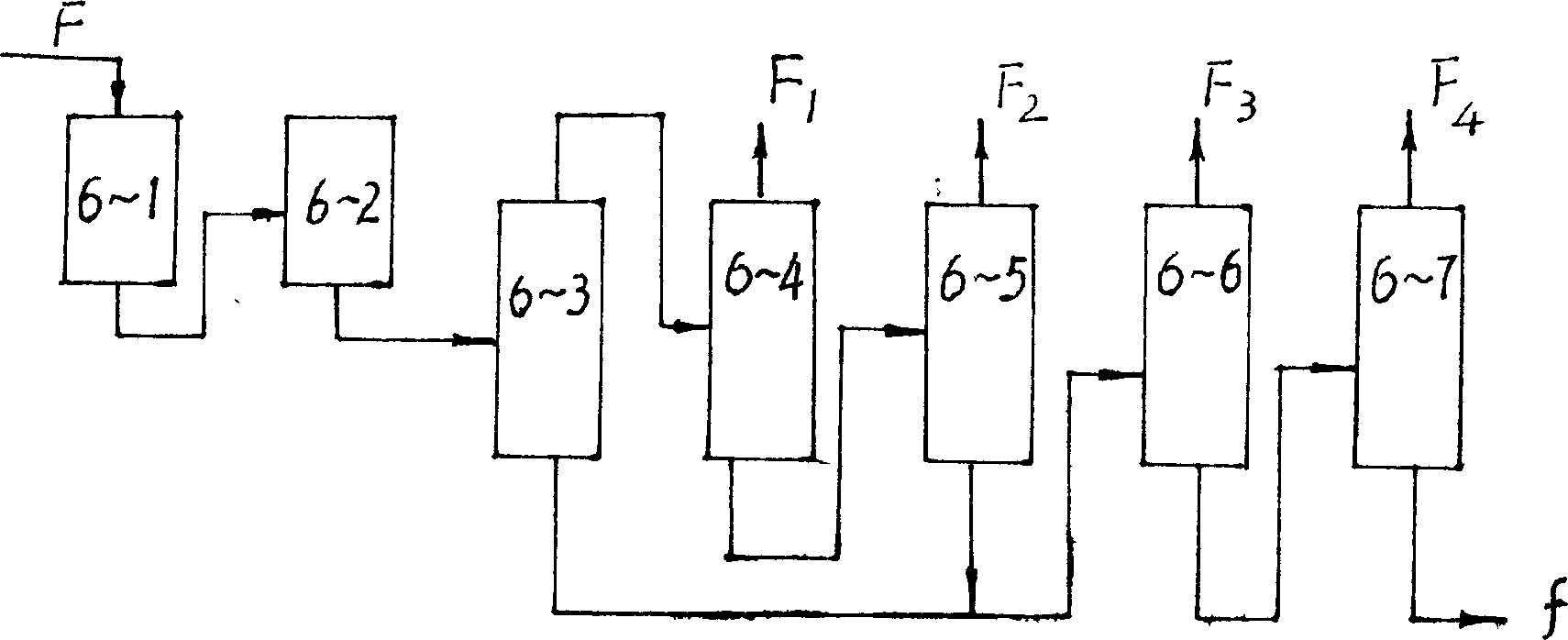

[0030] E. Separation treatment:

[0031] a. Initial dehydration: The mixture quen...

Embodiment 2

[0041] The reactor in this embodiment adopts an externally heated tubular reactor with a pipe diameter of φ14×2.

[0042]The feed rate of difluoro-chloroethane is 1500mol / h, preheated to 400°C, the dilution ratio is 13, the superheated steam temperature is 700°C, the materials are mixed into the reactor 4, and the reactor is continued to be heated so that the outlet temperature of the reactor reaches 680°C , The reaction residence time is 0.1s (seconds). All the other processes are the same as in Example 1.

[0043] In this example, the conversion rate of vinylidene fluoride is 92%, the selectivity is 99.4%, and the purity of vinylidene fluoride separated by rectification is ≥99.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com