Pickled red beet root and pickling process

A mustard and process technology, applied in the field of red mustard and its pickling process, can solve the problems of improper selection of family and genus varieties, long construction period and many process links, etc., and achieve the effects of enriching raw material sources, shortening production cycle and improving nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

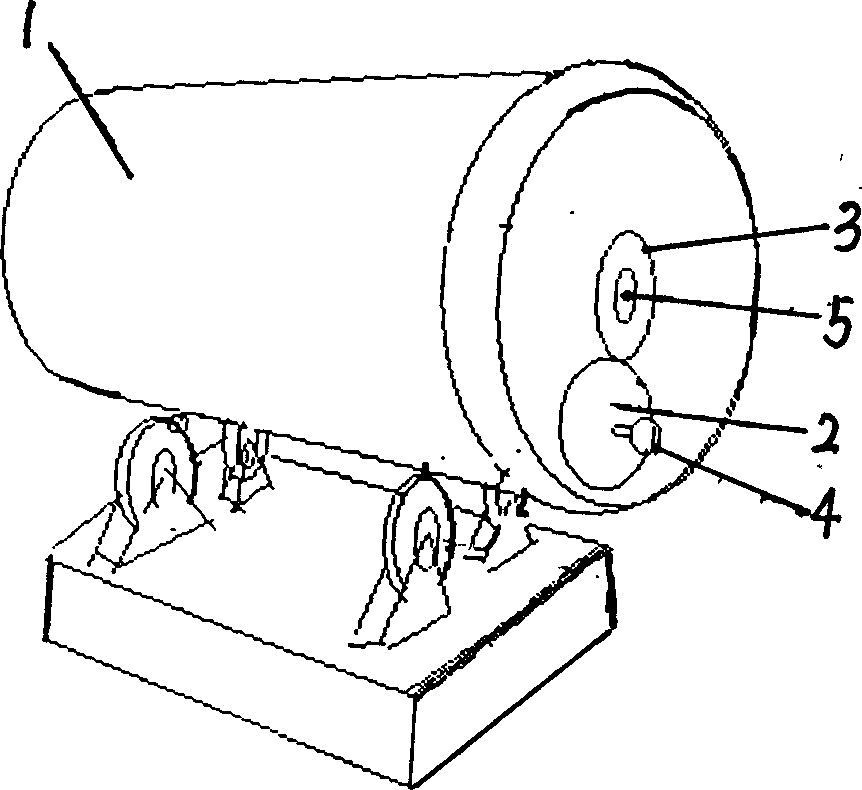

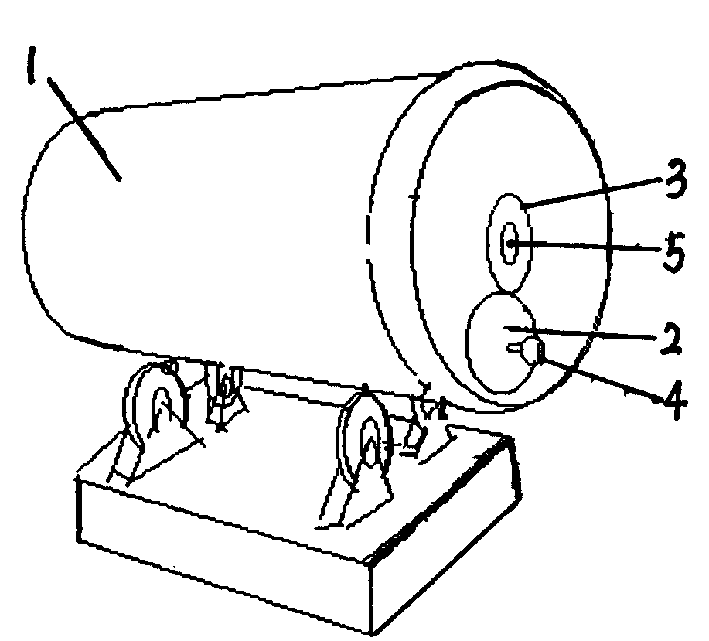

[0017] Select 100 kg of fresh magenta beets, cut off fibrous roots and residual stems, wash the sediment, cut into pieces, air-dry and dehydrate, and recover when 100 kg of fresh vegetables are dehydrated to about 80 kg. Add salt in a proportion of 4%, mix evenly, put it into a fermenter, and cover it with a sealing cover so that water and air cannot leak out. Start the fermenter, roll once every hour for 15 minutes on the first day, roll once every 6 hours for 10 minutes each on the second day, roll once every 12 hours for the 3rd-7th, 3 minutes each time, from Observed through the monitoring window, the salt water seeps out gradually until it covers the surface of the vegetable block. Starting from the second week, for the remaining 5-8 weeks, roll once every 12 hours for 3-5 minutes each time. Observed from the monitoring window, the brine increased day by day, and then gradually returned to the vegetable pieces. The rolling speed of the tank is controlled within the rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com