Vortex eliminating structure for two-way structure distribution container parallel connected pipe group

A distribution header and parallel technology, applied in the direction of mechanical equipment, fluid flow, etc., can solve the problems of uneven flow distribution, difference in flow distribution of parallel pipe groups, abnormality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

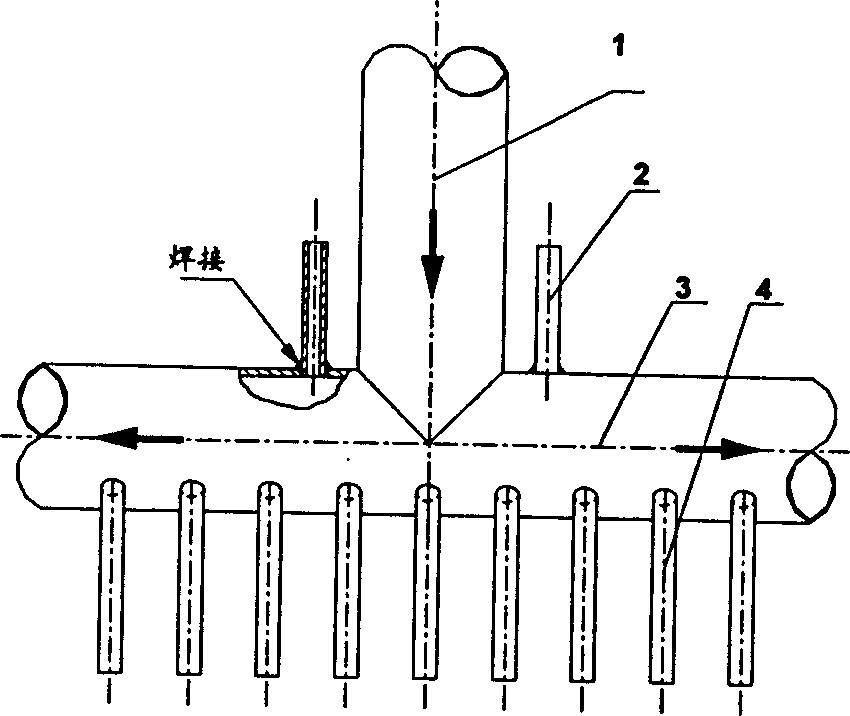

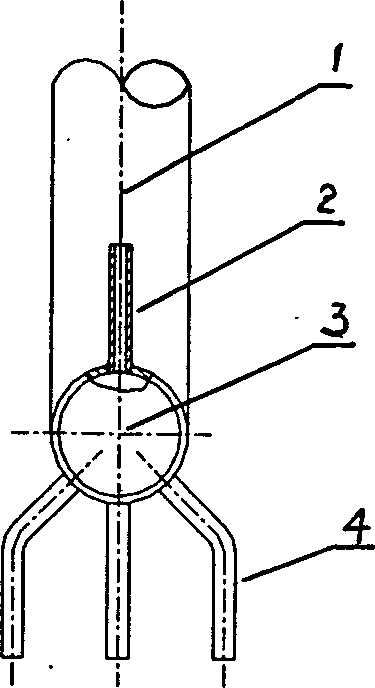

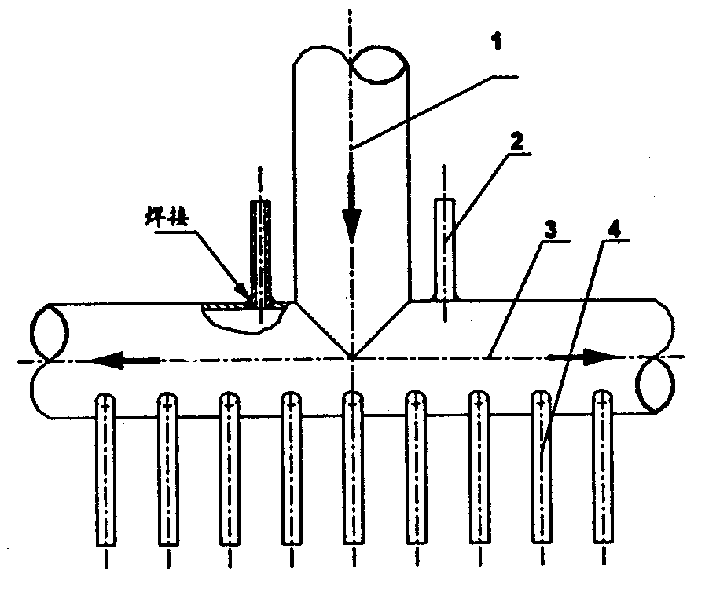

[0012] The vortex-eliminating structure of the distribution header parallel pipe group with a three-way structure of the present invention is as follows: figure 1 figure 2 As shown, in the parallel pipe group system, on the upper side of the distribution header 3 and on both sides of the three-way structure introduction conduit 1, two vortex elimination outlet branch pipes 2 are drilled and welded. The distance between the vortex-eliminating outlet branch pipe 2 and the axis of the introduction conduit 1 is 1.5 times the inner diameter of the introduction conduit 1, and the diameter of the vortex-elimination outlet branch pipe 2 is the same as that of the parallel tube group 4. The vortex elimination branch pipe 2 is directly introduced into the next stage header.

[0013] When the fluid flows, a vortex is generated near the tee in the header. Since the distribution header 3 is installed with a vortex-eliminating branch pipe 2, the fluid in the vortex area can be extracted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com